A leap forward in the application of ultrafast lasers

On 22 March 1960, American physicists Charles H. Townes and Arthur L. Schawlow were granted a patent for something called an optical maser. While this term might be unfamiliar to some of our readers, the majority will have heard of what it has become known as in the years after: lasers. Lasers are used in a wide range of different applications, from CD players, to medical applications and even self-driving cars!

However, the invention of lasers would not have been possible were it not for Max Planck’s discovery of elementary energy quanta (for which he received the 1918 Nobel Prize in physics). Later, Einstein suggested that it might be possible to stimulate electrons and make them emit light of a particular wavelength. As usual, Einstein was way ahead of his time and it was more than four decades after this that his theory was demonstrated in practice. So, what is a laser? Well, put simply, a laser is something that can make billions of atoms generate trillions of light particles (protons) that line up to produce a concentrated beam of light. So concentrated is this beam of light, that it makes lasers extremely precise and powerful.

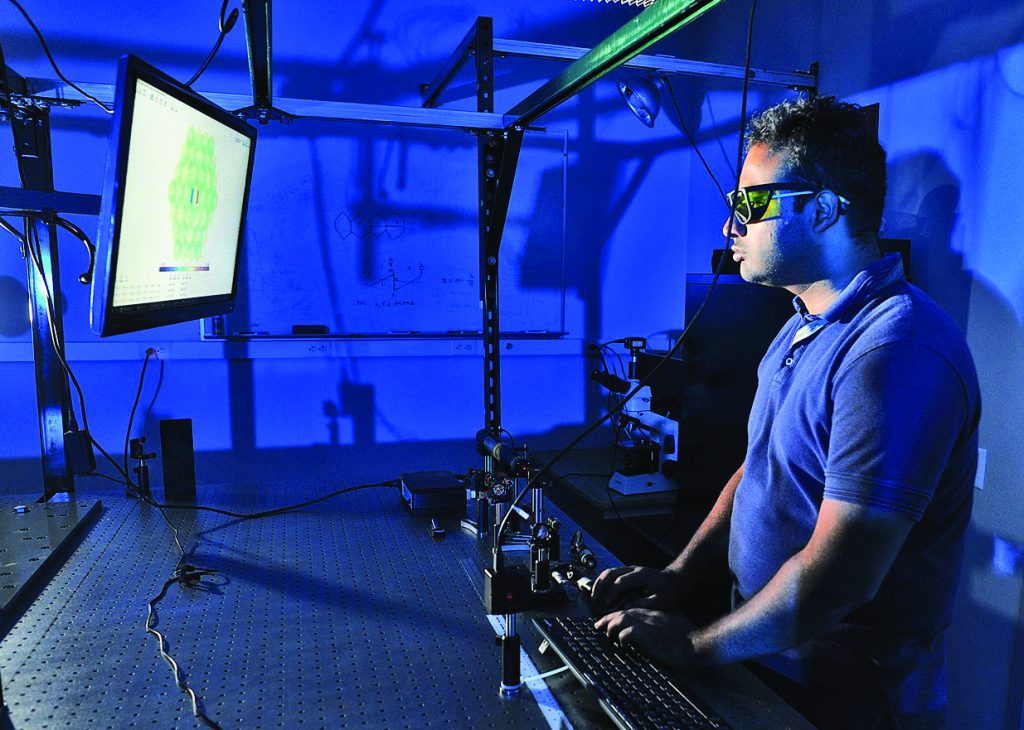

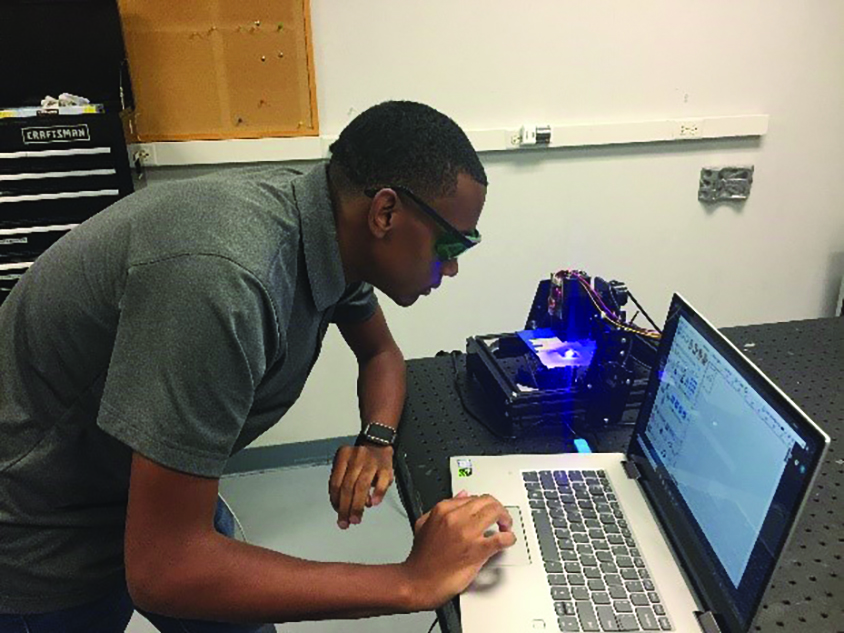

Now that we are firmly within the 21st century, technological advancements are enabling more developed lasers to be used in a range of applications, with enormous benefits across a range of fields. Dr Xiaoming Yu, who is based within CREOL, The College of Optics and Photonics at the University of Central Florida in the US, is working on using ultrafast lasers as a potential manufacturing tool – one that could lead to the development of new and improved medical devices (as well as many other possible applications).

WHAT ARE THE BENEFITS OF USING ULTRAFAST LASERS?

Firstly, lasers have the ability to modify materials from the inside! For instance, there are bubblegrams, which are solid blocks of glass that have been exposed to laser beams to produce 3D designs inside. The precision that enables these artworks to be created also has exciting applications in 3D printing to produce medical devices and even artificial tissues.

The second benefit is the high resolution that lasers boast, which means they have extremely small features – smaller than a red blood cell – which is where Xiaoming’s research comes in. They can do this because, unlike other types of laser, ultrafast lasers (also known as ultrashort-pulsed lasers) emit bursts of light that are unbelievably short. So short in fact that the light they emit travels a shorter distance than a fraction of the width of a human hair!

These ultrashort pulses are 100 trillion times brighter than sunlight. “When shining onto a material, these bursts create extremely high temperature and pressure that can only be found at explosion of thousands of tons of TNT or a small nuclear bomb, turning the material to a plasma (the fourth state of matter),” explains Xiaoming. “What is more important is that these bursts are so short that temperature does not have enough time to spread, so the plasma only affects a small area. This is called ‘nonthermal ablation’ and is unique to ultrafast lasers and the reason that small features can be made.”

HOW HAVE XIAOMING AND HIS TEAM WORKED TO DEVELOP THESE LASERS?

Xiaoming has developed a new process to fabricate large-area nanostructures on dielectric materials, that is, materials that do not conduct electricity. The new process is called Laser Etching by Avalanche-assisted Photoabsorption (LEAP), which uses the ultrashort laser pulses mentioned above. “LEAP uses multiphoton absorption and another photo-physical process called avalanche ionization, which means an ultrafast laser beam creates a cascade of energised electrons similar to an avalanche – one electron turns into two, then four, then eight, etc. This process repeats itself as long as there are new pulses coming in,” says Xiaoming. “In LEAP, such a process is controlled so precisely that the last pulse creates just enough energised electrons to form a nano-plasma, which is smaller than using multiphoton absorption only, so the resolution is enhanced.”

HAVE THERE BEEN ANY CHALLENGES IN THE RESEARCH?

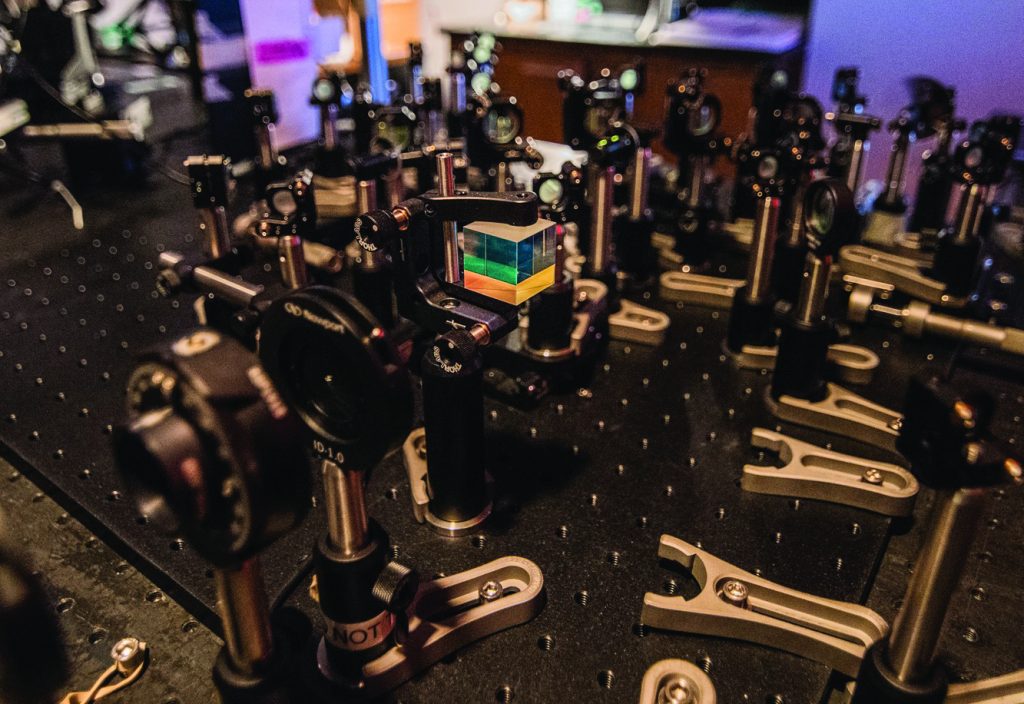

Yes! When working with these ultrashort pulses, it becomes extremely challenging to control them. Given that the pulse travels such an incredibly short distance, the slightest thing – like a slight misalignment of the beam or even movement in the air – can change the characteristics of the pulse. To overcome this, Xiaoming and the team designed their instrument in such a way that potential disturbances could be minimised and compensated for. “The entire instrument was built on a single piece of metal so each component would move in the same way if there was any vibration. We mounted the mirrors on motors so the timing of the pulses could be tuned precisely,” explains Xiaoming. “Since the pulses were so strong, we looked at and blocked every possible way the beam could escape and cause damage.”

Of course, alongside these experimental challenges there is the overall challenge regarding the big question the team want to answer: how to make ultrafast lasers a more versatile and useful manufacturing tool. Xiaoming is therefore spending time working to improve the concentration of the laser energy and deposit energy more efficiently.

WHAT ARE THE NEXT STEPS FOR THE RESEARCH?

Xiaoming and the team have focused on building the instrument for the experiment to prove that it can work. This has enabled them to develop a model that unifies the results from other researchers and acts as the basis of other findings on the ultimate resolution limit of ultrafast lasers. Over the course of their studies, they came across an unexpected result when two laser pulses were slightly misaligned, and the overlapped region created a feature that was smaller than that from each pulse individually! Discovered purely by chance, this helped demonstrate a way of enhancing the resolution.

Reference

https://doi.org/10.33424/FUTURUM127

On 22 March 1960, American physicists Charles H. Townes and Arthur L. Schawlow were granted a patent for something called an optical maser. While this term might be unfamiliar to some of our readers, the majority will have heard of what it has become known as in the years after: lasers. Lasers are used in a wide range of different applications, from CD players, to medical applications and even self-driving cars!

However, the invention of lasers would not have been possible were it not for Max Planck’s discovery of elementary energy quanta (for which he received the 1918 Nobel Prize in physics). Later, Einstein suggested that it might be possible to stimulate electrons and make them emit light of a particular wavelength. As usual, Einstein was way ahead of his time and it was more than four decades after this that his theory was demonstrated in practice. So, what is a laser? Well, put simply, a laser is something that can make billions of atoms generate trillions of light particles (protons) that line up to produce a concentrated beam of light. So concentrated is this beam of light, that it makes lasers extremely precise and powerful.

Now that we are firmly within the 21st century, technological advancements are enabling more developed lasers to be used in a range of applications, with enormous benefits across a range of fields. Dr Xiaoming Yu, who is based within CREOL, The College of Optics and Photonics at the University of Central Florida in the US, is working on using ultrafast lasers as a potential manufacturing tool – one that could lead to the development of new and improved medical devices (as well as many other possible applications).

WHAT ARE THE BENEFITS OF USING ULTRAFAST LASERS?

Firstly, lasers have the ability to modify materials from the inside! For instance, there are bubblegrams, which are solid blocks of glass that have been exposed to laser beams to produce 3D designs inside. The precision that enables these artworks to be created also has exciting applications in 3D printing to produce medical devices and even artificial tissues.

The second benefit is the high resolution that lasers boast, which means they have extremely small features – smaller than a red blood cell – which is where Xiaoming’s research comes in. They can do this because, unlike other types of laser, ultrafast lasers (also known as ultrashort-pulsed lasers) emit bursts of light that are unbelievably short. So short in fact that the light they emit travels a shorter distance than a fraction of the width of a human hair!

These ultrashort pulses are 100 trillion times brighter than sunlight. “When shining onto a material, these bursts create extremely high temperature and pressure that can only be found at explosion of thousands of tons of TNT or a small nuclear bomb, turning the material to a plasma (the fourth state of matter),” explains Xiaoming. “What is more important is that these bursts are so short that temperature does not have enough time to spread, so the plasma only affects a small area. This is called ‘nonthermal ablation’ and is unique to ultrafast lasers and the reason that small features can be made.”

HOW HAVE XIAOMING AND HIS TEAM WORKED TO DEVELOP THESE LASERS?

Xiaoming has developed a new process to fabricate large-area nanostructures on dielectric materials, that is, materials that do not conduct electricity. The new process is called Laser Etching by Avalanche-assisted Photoabsorption (LEAP), which uses the ultrashort laser pulses mentioned above. “LEAP uses multiphoton absorption and another photo-physical process called avalanche ionization, which means an ultrafast laser beam creates a cascade of energised electrons similar to an avalanche – one electron turns into two, then four, then eight, etc. This process repeats itself as long as there are new pulses coming in,” says Xiaoming. “In LEAP, such a process is controlled so precisely that the last pulse creates just enough energised electrons to form a nano-plasma, which is smaller than using multiphoton absorption only, so the resolution is enhanced.”

HAVE THERE BEEN ANY CHALLENGES IN THE RESEARCH?

Yes! When working with these ultrashort pulses, it becomes extremely challenging to control them. Given that the pulse travels such an incredibly short distance, the slightest thing – like a slight misalignment of the beam or even movement in the air – can change the characteristics of the pulse. To overcome this, Xiaoming and the team designed their instrument in such a way that potential disturbances could be minimised and compensated for. “The entire instrument was built on a single piece of metal so each component would move in the same way if there was any vibration. We mounted the mirrors on motors so the timing of the pulses could be tuned precisely,” explains Xiaoming. “Since the pulses were so strong, we looked at and blocked every possible way the beam could escape and cause damage.”

Of course, alongside these experimental challenges there is the overall challenge regarding the big question the team want to answer: how to make ultrafast lasers a more versatile and useful manufacturing tool. Xiaoming is therefore spending time working to improve the concentration of the laser energy and deposit energy more efficiently.

WHAT ARE THE NEXT STEPS FOR THE RESEARCH?

Xiaoming and the team have focused on building the instrument for the experiment to prove that it can work. This has enabled them to develop a model that unifies the results from other researchers and acts as the basis of other findings on the ultimate resolution limit of ultrafast lasers. Over the course of their studies, they came across an unexpected result when two laser pulses were slightly misaligned, and the overlapped region created a feature that was smaller than that from each pulse individually! Discovered purely by chance, this helped demonstrate a way of enhancing the resolution.

The next steps are to use the instrument to produce pulses with characteristics in favour of the aforementioned avalanche process. “We will make the laser beam go into a small focus and use it to fabricate nanostructures on the surface and in the bulk of glass samples,” says Xiaoming. “Ultimately, my work can be used in the fabrication of medical devices, such as stents and scaffolds, laser surgery and the processing of display panels. In addition, smartphone panels are processed by lasers and my work will make the manufacturing of these materials more precise and error-free.”

DR XIAOMING YU

DR XIAOMING YU

Assistant Professor of Optics & Photonics, CREOL, The College of Optics and Photonics, University of Central Florida, USA.

FIELD OF RESEARCH: Optics and Photonics

RESEARCH PROJECT: Developing a new nanomanufacturing process that can be used in the fabrication of medical devices and display panels. The findings will improve various aspects of our lives.

FUNDERS: National Science Foundation

DR XIAOMING YU

DR XIAOMING YU

Assistant Professor of Optics & Photonics, CREOL, The College of Optics and Photonics, University of Central Florida, USA.

FIELD OF RESEARCH: Optics and Photonics

RESEARCH PROJECT: Developing a new nanomanufacturing process that can be used in the fabrication of medical devices and display panels. The findings will improve various aspects of our lives.

FUNDERS: National Science Foundation

ABOUT OPTICS AND PHOTONICS

The word photonics comes from the Greek word ‘phos’ meaning light (and is also the reason we call particles of light photons). The invention of the laser in 1960 gave rise to the field of photonics, which is closely related to optics. However, optics was established far before photonics, with the development of lenses for microscopes, the refracting lens and the reflecting mirror. Of course, with the advent of significant technological developments, researchers have been able to advance the field of photonics in considerable ways, particularly those related to fields like quantum optics and quantum electronics.

WHAT DOES XIAOMING FIND MOST REWARDING ABOUT HIS RESEARCH?

Xiaoming is a pioneer in the fields of optics and photonics; he has developed many techniques that have since been used by other researchers to solve real-world problems. “A technique I developed when I was a graduate student – ‘polarisation-sensitive chemical etching’ – has been used to fabricate microfluidic chips used in large chemical plants,” explains Xiaoming. “I am collaborating with a US manufacturer of fabric-processing machines which will be using ultrafast lasers as the main processing tool. I hope the LEAP method, once fully developed in the current project, will help laser processing companies reduce cost and increase throughput.”

WHAT TYPES OF COLLABORATION HIS XIAOMING ENGAGED IN?

Since lasers were invented more than 60 years ago, the field has been interdisciplinary by nature and that continues to the present day. Xiaoming is currently working with a chemist to develop a new material suitable for 3D printing and a mechanical engineer to develop a multi-physics model that will help to understand different types of laser-induced phenomena. And then, of course, there is the team he collaborates with at his college at CREOL.

WHAT WILL THE NEXT GENERATION OF SCIENTISTS ENGAGED IN OPTICS AND PHOTONICS BE FOCUSING ON?

Even though this field has been studied for more than half a century and a lot has been learned about the interaction between ultrashort laser pulses and solid materials, Xiaoming is confident that this complex and fascinating topic has only had its surface scratched. “On the theory side, many models dealing with steady-state phenomena would not work under the extreme temperature and pressure environment induced by the ultrafast laser, so new theories need to be developed. Practically, ultrafast lasers are still difficult to use because of the stringent requirement on the environment,” says Xiaoming. “We need engineers to make ultrafast lasers ‘smarter’, so that they can sense any change in the environment and make adjustment by themselves. The physicist, Richard Feynman, once imagined a future when atoms can be manipulated individually to build things like nano-robots. We are far from this, but we are moving toward this goal with the new generation of scientists and engineers.”

HOW TO GET INVOLVED IN OPTICS AND PHOTONICS

• Optics.org is dedicated to providing daily coverage of the optics and photonics industry and the markets that it serves: https://optics.org/

• Photonics.com has a heady list of societies and associations to explore: https://www.photonics.com/EDU/EducationalInstitutions.aspx?TID=1

• The average salary for a photonics engineer in the US is approximately $99,000, although that figure can rise significantly for more experienced engineers.

PATHWAY FROM SCHOOL TO OPTICS AND PHOTONICS

Optics is a sub-field of physics, so basic physics courses are helpful, as well as mathematics courses that you will likely encounter in high school. “It is worth taking more advanced courses in subjects such as static and dynamic electromagnetics, solid state physics, linear algebra, matrices, linear systems, quantum mechanics and thermodynamics,” explains Xiaoming. “I also recommend taking as many chemistry and biology modules as possible because optics and photonics is a highly interdisciplinary field.”

You will need a degree in a relevant subject for postgraduate study. https://www.careerexplorer.com/careers/photonics-engineer/

HOW DID XIAOMING BECOME AN EXPERT IN OPTICS AND PHOTONICS?

WHAT WERE YOUR INTEREST AS A CHILD?

I liked astronomy when I was young, which was an interest that was partly influenced by Stephen Hawking’s book ‘A Brief History of Time’ and partly because a night sky always triggered my imagination about the many unknown worlds beyond our reach. I liked reading magazines about science and technology and enjoyed tinkering with (often destroying) things that had moving parts in them. I guess it was because I wanted to know how stuff worked – that’s how I explained it anyway!

WHO INSPIRED YOU TO BECOME A SCIENTIST?

Famous scientists like Stephen Hawking and Richard Feynman, mainly through their books. I was inspired by my high school physics teacher, who taught me the power of science. Using nothing but imagination, logic and perhaps a piece of paper and a pencil, Newton was able to declare a law that every object in the universe must obey. I became fascinated by science after learning about this in high school.

WHAT ATTRIBUTES HAVE MADE YOU SUCCESSFUL AS A SCIENTIST?

I wouldn’t call myself successful! There are so many things to learn which, I guess, counts as an attribute – the acknowledgement that there is always something new to learn. Another key attribute is critical thinking, which is the ability to provide independent assessment of facts and opinions. The third attribute is persistence. There will be challenges in research and many of them have not been solved or even encountered before. It is in such moments that scientists and researchers need to hold on to their beliefs and try everything they can. Every problem has a solution.

HOW DO YOU OVERCOME OBSTACLES IN YOUR WORK?

Learning from others. The majority of problems can be solved using my own knowledge and experience, but once in a while there are problems that exceed my ability. Instead of trying to force myself to work on the problem, I seek help from others – and not always those who have the exact expertise, but anybody who has an open mind and is willing to share their opinions from a different perspective. I find this often broadens my views and helps me solve problems using a new approach.

WHAT AMBITIONS HAVE YOU SET YOURSELF FOR THE FUTURE?

I would like to see laser materials processing, in general, and ultrafast laser processing, in particular, become more widely used manufacturing tools. Lasers are versatile in that they can be tailored to suit different types of applications, like a swiss army knife. I would like to continue my contribution in this field and my biggest ambition is to build a ‘universal laser machine’ that can do different jobs and is accessible to the public. I like to think of this as a personal workshop which ordinary people could use to build the parts they need in a way as simple as clicking a few buttons.

XIAOMING’S TOP TIPS

01 Have confidence in everything that you do. Always keep in mind that every piece of technology you are using in the present moment was invented by people just like you.

02 Keep an open mind and consider every opinion, particularly criticisms, which are often the best advice you can have to improve yourself.

03 Never be afraid of making mistakes – the important thing is to learn from your mistakes. Do not let the fear of failure stop you from dreaming big but remember to always examine your ideas carefully.

Do you have a question for Xiaoming?

Write it in the comments box below and Xiaoming will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)