Can a circular economy make the construction industry sustainable?

The construction industry is responsible for 40% of the UK’s greenhouse gas emissions. Dr Danielle Densley Tingley of the University of Sheffield’s Department of Civil and Structural Engineering in the UK is investigating how to make buildings more sustainable by reusing and recycling everything in them

TALK LIKE A LOW CARBON ENGINEER

BUILDING STOCK – the total number of buildings in a given area and the materials stocked within them

BUILT ENVIRONMENT – everything made, arranged and maintained by humans as the setting for human activities, including homes, commercial buildings, government buildings and roadways

CIRCULAR ECONOMY – an economic system that minimises use of resources and creation of waste by sharing, reusing, recycling, and repairing products instead of manufacturing new ones

DECARBONISE – reduce the amount of carbon emitted from the built environment

EMBODIED CARBON – the greenhouse gases produced when making materials, including the extraction of raw materials from the earth, transportation, processing, manufacturing, installation, maintenance and end of life

RETROFIT – the introduction of new materials or technology into a pre-existing building to make it more energy efficient (retrospectively)

One of the largest sources of the greenhouse gas emissions that drive global warming is the construction industry.

Construction accounts for roughly 40% of the UK’s greenhouse gas emissions. Some of these emissions are embodied – generated by the manufacturing and transport of materials like steel and concrete, rather than emitted directly by the buildings themselves. Other emissions are produced by building operations like heating and cooling or the use of electricity. Dr Danielle Densley Tingley, at the Department of Civil and Structural Engineering of the University of Sheffield, researches strategies for making construction sustainable by reducing the use of new resources.

Instead of using new steel and concrete, the sustainable construction industry of the future needs to be a circular economy: reusing old buildings for new purposes where possible, and reusing building elements and materials from old buildings when new ones are needed. Danielle is working on a project to collect information about the materials currently locked up in the UK’s existing building stock.

CONSTRUCTION AND GLOBAL WARMING

Buildings cause operational emissions – greenhouse gases emitted when using the built environment (for example, by heating and using electricity to run computers and home appliances). Switching to a green electric grid can help reduce operational emissions, as can behavioural changes like opening a window instead of turning on air conditioning or heating homes to 18 degrees instead of 20. Improving a building’s energy efficiency by installing modern insulation or double glazing also reduces operational emissions.

But, construction is also a major source of embodied emissions. Many of the materials used in buildings are difficult to decarbonise because producing them creates greenhouse gas emissions inherently. For example, the chemical reactions involved in making cement, a key component of concrete, naturally produce carbon dioxide, so the industry is exploring alternatives to Portland cement, which is the type most typically used. “You can have concrete without emissions,” explains Danielle, “but for various reasons, this is not currently done at scale.”

Researchers are looking for alternative building materials instead, including organic ones. The construction industry is also very resource-intensive, using over 400 million tonnes of natural resources every year – a rate that cannot be sustained indefinitely. Both emissions and resource use can be reduced by making fewer fresh materials and reusing existing stocks. This is what the circular economy aims to do.

A CIRCULAR ECONOMY

Our current economic system is linear. We extract natural resources, process and manufacture them into products, and discard the products as waste when we no longer need them. In a circular economy, both resource extraction and waste are kept to a minimum by retaining materials in use as long as possible. A circular economy involves a hierarchy of strategies for using materials over their lifetime. Danielle explains, “For the construction sector, this translates to keeping a building for as long as possible, reusing components and materials as the next option, then remanufacturing, then recycling, downcycling and, finally, incineration or disposal if none of the above can be achieved.”

An effective circular economy in the construction industry would require new ways of designing buildings. Danielle describes these as “design for adaptability” and “design for deconstruction and reuse.” Designing buildings for adaptability means designing them to accommodate changing user needs and a changing climate. Whole buildings should be able to serve different purposes at different times, with minimal change to their structure. Designing for reuse, on the other hand, means creating buildings in a modular way so that they can be taken apart and individual components can be incorporated into other structures. Instead of being demolished when no longer needed, buildings like these would be deconstructed and put back together in new forms – like LEGO bricks.

MOVING TO A CIRCULAR, LOWCARBON CONSTRUCTION INDUSTRY

Decarbonising the construction industry and turning it into a circular economy is challenging. Decarbonising the existing building stock requires expensive work, like retrofitting building fabric by replacing insulation and installing double glazing. It also requires switching from gas boilers to renewable energy sources for heating, such as air or ground source heat pumps. Retrofitting the 29 million homes in the UK is an urgent and significant task.

Reference

https://doi.org/10.33424/FUTURUM205

BUILDING STOCK – the total number of buildings in a given area and the materials stocked within them

BUILT ENVIRONMENT – everything made, arranged and maintained by humans as the setting for human activities, including homes, commercial buildings, government buildings and roadways

CIRCULAR ECONOMY – an economic system that minimises use of resources and creation of waste by sharing, reusing, recycling, and repairing products instead of manufacturing new ones

DECARBONISE – reduce the amount of carbon emitted from the built environment

EMBODIED CARBON – the greenhouse gases produced when making materials, including the extraction of raw materials from the earth, transportation, processing, manufacturing, installation, maintenance and end of life

RETROFIT – the introduction of new materials or technology into a pre-existing building to make it more energy efficient (retrospectively)

One of the largest sources of the greenhouse gas emissions that drive global warming is the construction industry.

Construction accounts for roughly 40% of the UK’s greenhouse gas emissions. Some of these emissions are embodied – generated by the manufacturing and transport of materials like steel and concrete, rather than emitted directly by the buildings themselves. Other emissions are produced by building operations like heating and cooling or the use of electricity. Dr Danielle Densley Tingley, at the Department of Civil and Structural Engineering of the University of Sheffield, researches strategies for making construction sustainable by reducing the use of new resources.

Instead of using new steel and concrete, the sustainable construction industry of the future needs to be a circular economy: reusing old buildings for new purposes where possible, and reusing building elements and materials from old buildings when new ones are needed. Danielle is working on a project to collect information about the materials currently locked up in the UK’s existing building stock.

CONSTRUCTION AND GLOBAL WARMING

Buildings cause operational emissions – greenhouse gases emitted when using the built environment (for example, by heating and using electricity to run computers and home appliances). Switching to a green electric grid can help reduce operational emissions, as can behavioural changes like opening a window instead of turning on air conditioning or heating homes to 18 degrees instead of 20. Improving a building’s energy efficiency by installing modern insulation or double glazing also reduces operational emissions.

But, construction is also a major source of embodied emissions. Many of the materials used in buildings are difficult to decarbonise because producing them creates greenhouse gas emissions inherently. For example, the chemical reactions involved in making cement, a key component of concrete, naturally produce carbon dioxide, so the industry is exploring alternatives to Portland cement, which is the type most typically used. “You can have concrete without emissions,” explains Danielle, “but for various reasons, this is not currently done at scale.”

Researchers are looking for alternative building materials instead, including organic ones. The construction industry is also very resource-intensive, using over 400 million tonnes of natural resources every year – a rate that cannot be sustained indefinitely. Both emissions and resource use can be reduced by making fewer fresh materials and reusing existing stocks. This is what the circular economy aims to do.

A CIRCULAR ECONOMY

Our current economic system is linear. We extract natural resources, process and manufacture them into products, and discard the products as waste when we no longer need them. In a circular economy, both resource extraction and waste are kept to a minimum by retaining materials in use as long as possible. A circular economy involves a hierarchy of strategies for using materials over their lifetime. Danielle explains, “For the construction sector, this translates to keeping a building for as long as possible, reusing components and materials as the next option, then remanufacturing, then recycling, downcycling and, finally, incineration or disposal if none of the above can be achieved.”

An effective circular economy in the construction industry would require new ways of designing buildings. Danielle describes these as “design for adaptability” and “design for deconstruction and reuse.” Designing buildings for adaptability means designing them to accommodate changing user needs and a changing climate. Whole buildings should be able to serve different purposes at different times, with minimal change to their structure. Designing for reuse, on the other hand, means creating buildings in a modular way so that they can be taken apart and individual components can be incorporated into other structures. Instead of being demolished when no longer needed, buildings like these would be deconstructed and put back together in new forms – like LEGO bricks.

MOVING TO A CIRCULAR, LOW CARBON CONSTRUCTION INDUSTRY

Decarbonising the construction industry and turning it into a circular economy is challenging. Decarbonising the existing building stock requires expensive work, like retrofitting building fabric by replacing insulation and installing double glazing. It also requires switching from gas boilers to renewable energy sources for heating, such as air or ground source heat pumps. Retrofitting the 29 million homes in the UK is an urgent and significant task.

Designing new buildings to promote a circular economy is also not easy. Circular building design is an active area of research, with much information and social infrastructure still missing. There are not yet many incentives for circular building design. Large up-front investments are required to achieve benefits at some point in the future, and little regulation exists to encourage circular design. Builders may not be aware of circular design principles or their importance. However, some progress is being made: the Greater London Authority in the UK now requires large development schemes to submit a circular economy statement as part of their planning applications. The statement requires a plan for waste reduction and the reporting of key metrics such as material intensity (kg of material used per m2 of floor area) and reused or recycled content.

ADDRESSING THE PROBLEM WITH LOW CARBON ENGINEERING

Danielle’s research directly addresses the lack of information needed to design a circular economy in construction. With postdoctoral researcher Maud Lanau, Danielle develops detailed case studies, cataloguing how many bricks, steel beams, and other building components are in a building and how they are connected to each other. The case studies are categorised by the purpose and structural type of the building. They are then used as a basis to estimate material stocks in the UK’s built environment as a whole and to assess the circular economy potential of the stock. “This means assessing the adaptability of existing buildings,” Danielle explains, “and the reuse and recycling potential within the stock. What steel beams can be salvaged and directly reused again as steel beams? If steel can’t be directly reused, it can be melted down to form a different steel product.”

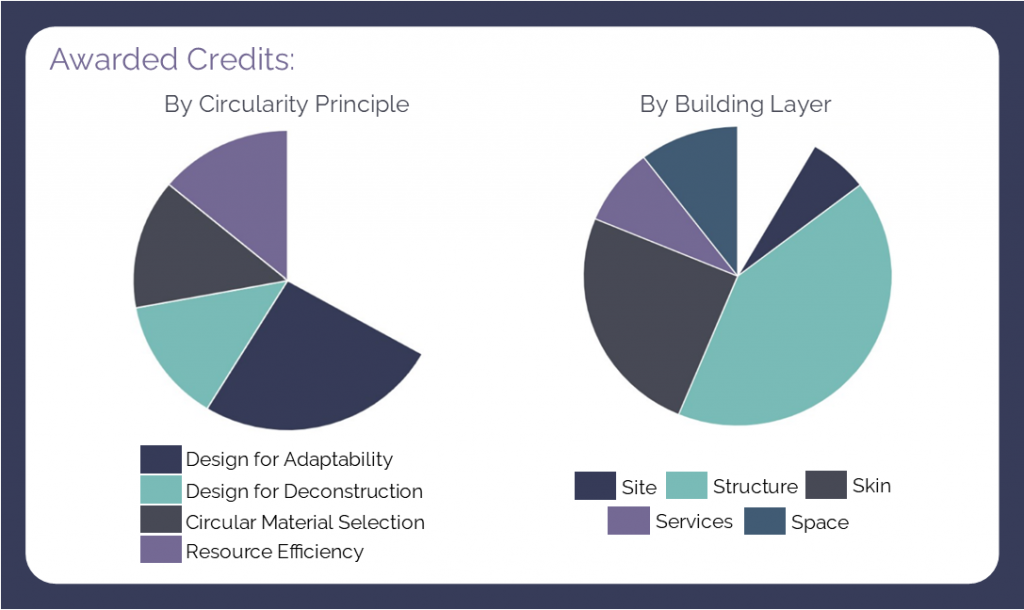

With two of her PhD students, Will Mihkelson and Charles Gillott, Danielle has developed a tool called Regenerate to measure the circularity of a building design. Regenerate assesses four core circularity principles: design for deconstruction, design for adaptability, circular material selection, and resource efficiency. The circularity criteria are looked at for five building layers – site, structure, skin, services and space – giving an overall estimate of how well the building plan meets the goals of a circular economy. Regenerate is an interactive web tool and is available for anyone to use for free. “Regenerate is being used by the construction sector to explore the circularity of their building designs, to show where improvements could be made,” Danielle says. “Hopefully, this will lead to more circular designs and, ultimately, a more resource-efficient built environment!”

DR DANIELLE DENSLEY TINGLEY

DR DANIELLE DENSLEY TINGLEY

Senior Lecturer in Architectural Engineering, Department of Civil and Structural Engineering, University of Sheffield, UK

FIELD OF RESEARCH: Sustainable Management and Conservation of Resources, Circular Economy

RESEARCH PROJECT: Developing a multi-scale framework to assess the circular economy potential of individual buildings, cities and countries

FUNDER: Engineering and Physical Sciences Research Council

DR DANIELLE DENSLEY TINGLEY

DR DANIELLE DENSLEY TINGLEY

Senior Lecturer in Architectural Engineering, Department of Civil and Structural Engineering, University of Sheffield, UK

FIELD OF RESEARCH: Sustainable Management and Conservation of Resources, Circular Economy

RESEARCH PROJECT: Developing a multi-scale framework to assess the circular economy potential of individual buildings, cities and countries

FUNDER: Engineering and Physical Sciences Research Council

The Urban Flow team working at home during the pandemic. Top row, from left to right: Xinyi Li, Danielle Densley Tingley, Will Mihkelson, Ling Ming Tan. Bottom row. left to right: Maud Lanau, Charles Gillot, Menglin Dai.

The Urban Flow team working at home during the pandemic. Top row, from left to right: Xinyi Li, Danielle Densley Tingley, Will Mihkelson, Ling Ming Tan. Bottom row. left to right: Maud Lanau, Charles Gillot, Menglin Dai.

ABOUT LOW CARBON ENGINEERING

Danielle’s specialism in low carbon engineering is part of the broader field of architectural engineering – a multi-disciplinary approach to the design, construction and operation of buildings. Architectural engineers consider the design of a building’s structure, materials, and environmental systems (lighting, heating, and so on) in an integrated way and are at the forefront of solving problems such as achieving a sustainable, low-carbon construction industry. Architectural engineering is both an art and a science, blending creative design and quantitative analysis.

With her focus on the circular economy and low carbon construction, Danielle is passionate about using her engineering skills to reduce the impact of the built environment on the planet. “My research explores sustainable building design solutions, focusing on material impacts, so we can create a built environment that operates within the carrying capacity of the planet,” she explains.

HOW CAN ENGINEERS HELP US ACHIEVE NET ZERO EMISSIONS?

Achieving net zero in the construction industry will require new technologies and huge changes in the design of the built environment. Behavioural change is also key, as people must adapt to using fewer resources. Engineers in industry will be critical to finding creative design solutions to the problems of decarbonisation and sustainability. In academia, much more research is needed about the circular economy. This research includes understanding our current material building stock and how much of it can be reused or recycled. It will also need to investigate the effectiveness of different building designs for promoting sharing and reuse of buildings or deconstruction and recycling of materials. Finally, the behavioural aspect of how we use buildings must be understood if we want to design buildings to encourage more sustainable ways of interacting with the built environment. All of these approaches are ways young researchers and engineers can contribute to a sustainable, low-carbon construction industry.

ARE THERE ANY EXAMPLES OF CONSTRUCTION COMPANIES ALREADY PARTICIPATING IN THE CIRCULAR ECONOMY TODAY?

Yes! A company called Gamle Mursten (‘Old Bricks’) salvages old bricks and uses a patented cleaning technology so they can be reused instead of discarded as waste. This saves 95% of the energy that would be used to make new bricks. Saving 2,000 bricks prevents one tonne of CO2 from being emitted into the atmosphere. In another example, the company RGS90 takes old building insulation and processes, sorts, and recycles it by sending it to partner companies to be turned into new, recyclable insulation. Other companies are working on bioconcrete, eco-friendly concrete alternatives grown from bacteria or fungi. Environmental engineering and the circular economy are wide-open fields for young researchers to make a difference.

EXPLORE A CAREER IN LOW CARBON ENGINEERING

• Low carbon engineering offers many career opportunities outside academia. Architecture firms like Perkins&Will or organicARCHITECT design eco-friendly buildings in line with circular economy principles. The need for sustainable construction will only grow as the world’s economy moves towards net zero carbon.

• Danielle’s alma mater, the University of Sheffield, is a top place to study and research low carbon structural engineering, architecture and architectural engineering in the UK at the post-graduate level.

PATHWAY FROM SCHOOL TO LOW CARBON ENGINEERING

• Danielle emphasises the interdisciplinary character of low carbon engineering, which combines maths, sciences and art. low carbon engineering is a good career for people who do not want to have to choose between the arts and the sciences.

• Danielle recommends studying maths as the most critical subject for engineering, but science is also very useful.

• There are lots of routes into low carbon engineering, including: structural engineering, architectural engineering and architecture.

• It is possible to do a PhD in fields such as architecture, structural engineering, design, or other subjects that support research in the circular economy. Low carbon engineering can also become chartered by the Chartered Institute of Building, the Institute of Structural Engineers or the Chartered Institute of Building Services Engineers and work in

industry on development projects.

HOW DID DANIELLE BECOME A LOW CARBON ENGINEER?

WHAT WERE YOUR INTERESTS WHEN YOU WERE GROWING UP?

At school I enjoyed maths, sciences and art – for a while I wanted to be a sculptor! I also considered marine biology to pursue my love of animals and science further. I eventually decided to do a degree in structural engineering and architecture as it combined my interests across maths, science and art. I stayed on to do a PhD after my degree because I wanted to make a difference in the world and felt that the way to do that was to become a built environment sustainability specialist.

WHO OR WHAT INSPIRED YOU TO BECOME AN ENGINEER?

I slightly fell into engineering through an enjoyment of maths, science and art. I was considering studying architecture, but realised that in the UK there’s little maths as part of the programme, so I studied a dual degree in structural engineering and architecture. It was during my degree that I fully appreciated (and developed) the problem-solving skills and creativity that you need to be a successful engineer.

WHAT ATTRIBUTES HAVE MADE YOU SUCCESSFUL AS AN ENGINEER?

Hard work and determination have got me a long way. I’m also a reasonably creative thinker and like tackling difficult problems.

WHAT ARE YOUR PROUDEST CAREER ACHIEVEMENTS SO FAR?

The proudest moment in my career so far was winning the funding for my ‘Multiscale, circular economic potential of non-residential building stock’ project. It was the first big project that I had led the application for, so it was a proud moment when the research council told me they were awarding the funding.

WHAT ARE YOUR AMBITIONS FOR THE FUTURE?

There’s lots of other research to do in this space, so going forward my aim is to win more funding in this field to further the research, and to do research that can make a recognisable difference in practice.

DANIELLE’S TOP TIPS

01 Remember that you can achieve almost anything if you set your mind to it and work hard.

02 Pursue something you’re genuinely passionate and excited about as this will make the hard work worthwhile, and sometimes it won’t even feel like work!

Do you have a question for Danielle?

Write it in the comments box below and Danielle will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)