Making metals: how are engineers developing new composite materials and manufacturing processes?

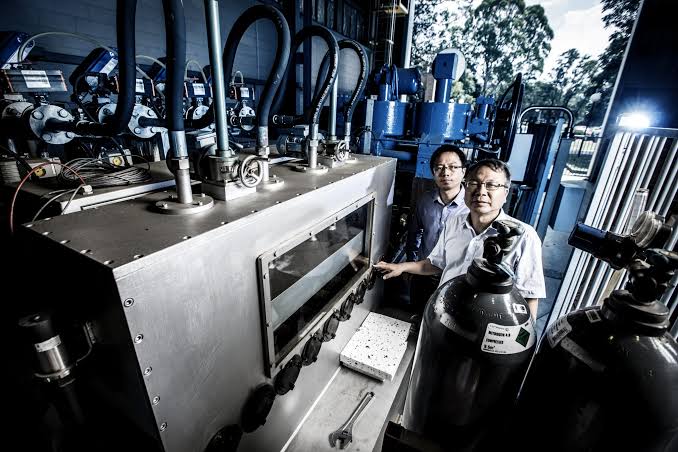

New composite materials are pushing the boundaries of what we can create. At the University of Wollongong in Australia, Distinguished Professor Zhengyi Jiang is at the forefront of this innovative pursuit. He is using his skills in materials and manufacturing engineering to create new metals that have a range of industrial applications and to improve metal manufacturing processes to make them more efficient, economic and environmentally friendly.

Talk like a materials and manufacturing engineer

Annealing — a process in which a metal is heated and cooled to make it less hard and more ductile

Casting — a process in which liquid metal is poured into a mould

Composite material — a manufactured material created by combining two or more substances which retain their original characteristics

Graphene — a material made of a single layer of carbon atoms

Lubricant — a substance that reduces friction and wear (e.g., oil)

Roll bonding — a process in which metal layers are passed through rotating rollers to fuse them together

Rolling reduction — a process in which metal is passed through rotating rollers to reduce its thickness

Steel — an alloy of iron and carbon (different types of steel contain different additional elements which give them different properties, e.g., stainless steel contains chromium and is resistant to rusting)

Welding — a process in which metals are joined together by heating the areas to be joined

The invention of new materials unlocks exciting possibilities for what we can create. Composite materials have a long history, from the construction materials developed by ancient civilisations to the components required in modern technologies. “Composite materials are made by combining two or more different substances to create a new material with improved material properties and functions,” explains Distinguished Professor Zhengyi Jiang, a materials and manufacturing academic at the University of Wollongong. “Each component retains its own characteristics, but together they form a new material that may be stronger, lighter or more durable than the individual components.”

Zhengyi is an international leader in developing innovative metallic composite materials. Not only does he invent new metals, but he also improves their manufacturing processes to make them more efficient, effective and environmentally friendly.

How does Zhengyi start to create a new material?

For most of human history, new composite materials have been created through trial and error, but today, simulation technologies make the process easier and more efficient. “To help predict what will happen to materials before we carry out physical experiments, we use numerical modelling and simulation techniques,” says Zhengyi. “These are essentially virtual experiments done on a computer.”

Zhengyi uses several simulation techniques to test potential new composite metals. For example, finite element analysis involves breaking a simulated metal object down into tiny individual parts, and testing how each part responds to stress, strain and temperature changes. “Computational fluid dynamics is another technique I use, which simulates how liquid metals flow and cool, which is useful in casting or welding processes,” explains Zhengyi. And molecular dynamics examines how the atoms inside a material move and interact, for example as the metal heats or cools. “Together, these techniques help us understand how metals behave during manufacturing processes,” says Zhengyi.

What new metals has Zhengyi developed?

Zhengyi and his team have developed many new composite metals that are now being used for a variety of industrial applications. For example, they have developed new types of high strength, wear-resistant steel. “For one steel, we combined stainless steel and carbon steel using rolling reduction at 950 °C followed by annealing at 850 °C,” Zhengyi explains. “For the other, we combined manganese steel with low-carbon steel using vacuum welding and roll bonding at 800-1100 °C.” These composite steels are ideal for heavy-duty applications in the mining industry, such as constructing the beds of trucks and conveyor chutes, which are constantly exposed to rocks and harsh environments that would quickly wear down other materials.

The team has also produced a new lightweight, corrosion-resistant steel. “We combined a strong carbon steel base with a thin corrosion-resistant layer of stainless steel by roll bonding,” says Zhengyi. “The resultant composite is suitable for many industrial applications in challenging environments. For example, its resistance to corrosion makes it ideal for ships and offshore platforms that are exposed to salt water.”

Additionally, Zhengyi has devised a new self-lubricating composite material. “This material is designed to reduce friction and wear for moving parts in machines, without the need for oil-based lubricants,” he says. “To create it, we mixed nano-sized powders of titanium carbide and graphene in a process known as powder blending, then heated the blended powder and pressed it into a solid shape, forming a strong, dense composite.” This self-lubricating material is ideal for making a wide range of machinery components, such as turbine blades for the aerospace and aviation industries, engine systems in cars, and for machines that operate in extreme environments where it is difficult to use oil-based lubricants, such as in space or underwater.

How is Zhengyi revolutionising manufacturing processes?

Reference

https://doi.org/10.33424/FUTURUM610

The city of Wollongong, where Zhengyi works © Taras Vyshnya/ Shutterstock.com

(All images featuring Zhengyi Jiang courtesy of the University of Wollongong)

As well as developing new composite materials, Zhengyi and his team are also specialised in improving their manufacturing processes. One project aims to reduce the energy needed for steel production. “Traditional hot-rolled steel production relies on oil-based lubricants,” says Zhengyi. “Our method, on the other hand, uses water-based nanolubricants combined with controlled oxidation and wear mechanisms.” These techniques include improved oxide scale-controlled hot rolling processes, as well as innovative applications of water-based nanolubrication. “This reduces energy consumption and production costs, lowers CO2 emissions, and enhances the surface quality and durability of the steel. Our approach balances performance, cost-efficiency and environmental responsibility in steel production.”

The team has also advanced the stainless steel manufacturing process. “Some stainless steels are created by rolling reduction,” explains Zhengyi. “However, oxide scale builds up on the rolled material and this damages the surface of the steel and creates friction which reduces efficiency and causes the rollers to wear out prematurely.” To address this issue, Zhengyi collaborated with Baosteel, the world’s largest steel company, to optimise oxidation conditions so that the oxide scale that builds up is easier to reshape. Not only did this reduce friction in the rollers, but it also improved lubrication in the rolling mill. “This led to improved surface quality of the stainless steel being produced and enhanced roller life in the production mills,” says Zhengyi. “We helped to make production at Baosteel more efficient and cost-effective.”

Through his collaborations with industry partners, Zhengyi is conducting groundbreaking research, making innovative new metals, and leading metal manufacturing processes into a new era.

Distinguished Professor Zhengyi Jiang

Distinguished Professor Zhengyi Jiang

Director, Australian Research Council Industrial Transformation Training Centre for Innovative Composites for the Future of Sustainable Mining Equipment

School of Mechanical, Materials, Mechatronic and Biomedical Engineering, University of Wollongong, Australia

Field of research: Materials and manufacturing engineering

Research interests: Developing new composite metals and metal manufacturing technologies

Project funders: Australian Research Council (ARC) and world leading steel manufacturing companies such as Baosteel (China)

About materials and manufacturing engineering

Materials and manufacturing engineering involves developing new materials and processes for manufacturing purposes. “A typical day might involve designing and analysing materials, improving production processes, conducting lab tests, solving technical issues and collaborating as a team,” says Zhengyi. “Communication is not restricted to the team – we often communicate with colleagues and communities all over the world.”

Collaboration between academia and industry is crucial, given that it is industrial processes and products that typically stand to benefit most directly from research in the field. “These collaborations combine research expertise with practical needs, leading to faster innovation and development of technologies that provide real-world solutions,” explains Zhengyi. “It also involves working with end users to understand their needs and expectations to refine and optimise the end products.”

Engineers are constantly innovating and improving materials and manufacturing processes, meaning the realm of possibilities is constantly growing. “For the next generation of engineers, smart materials, sustainable composites and nanomaterials will be big areas of study,” says Zhengyi. “New and emerging technologies like 3D printing, intelligent manufacturing and AI-driven process automation and optimisation provide exciting opportunities for the field.” Virtually every sector can stand to benefit from these advances in materials and manufacturing engineering. Aerospace, medicine and energy in particular could be on the cusp of dramatic improvements.

Pathway from school to materials and manufacturing engineering

Zhengyi recommends developing a strong foundation in mathematics, physics, chemistry, and design and technology at high school.

For an academic career, study an undergraduate degree in materials science and engineering, mechanical engineering, manufacturing processes or industrial design.

For a vocational career, look for apprenticeships, technical qualifications (e.g., at a Technical and Further Education Institute in Australia) or diplomas in engineering or manufacturing, which offer hands-on experience and can lead directly to employment or further university studies.

Explore careers in materials and manufacturing engineering

A career in materials and manufacturing engineering will allow you to solve real-world challenges by designing, creating and testing new materials and manufacturing processes.

This is Engineering explains what a career in materials engineering could look like and lists the skills and qualifications you will need.

For Australian students, Zhengyi recommends looking into professional societies such as Engineers Australia, Materials Australia and the Australian Ceramics Society for networking opportunities, industry insights and career development.

The School of Mechanical, Materials, Mechatronic and Biomedical Engineering, where Zhengyi works, runs outreach initiatives for school students.

According to Talent.com, the average materials engineer in Australia makes around AUS $95,000 per year.

Meet Zhengyi

My dream to pursue a career in materials and manufacturing engineering began when I was a teenager. I was interested in science, maths, physics, building things, solving problems and understanding how materials and machines work.

Various teachers, engineers and inventors were inspiring role models for me. They built my passion for innovation and my interest in the design and manufacture of machine components.

As a materials and manufacturing engineer, I enjoy being able to solve real-world problems. I find it rewarding to see my work used in products and technologies that make a difference. For example, I am proud of my contributions to developing sustainable materials and water-based nanolubricants because they solve a wide range of manufacturing challenges and support environmental goals.

The biggest challenges in this field are around balancing performance, cost and sustainability, while meeting strict industry standards and deadlines.

I have a lot of experience in linking academia with industry. This has led to large-scale funding from the Australian Research Council and many industry partners, which means our research outcomes can be directly applied to where they will make the most impact.

I enjoy training the next generation of engineers and young professionals. Since 2002, I have supervised hundreds of students and research fellows. It’s rewarding to see these new professionals go on to secure amazing jobs in industry. As Director of the Australian Research Council Industrial Transformation Training Centre for Innovative Composites for the Future of Sustainable Mining Equipment, I am helping to train young engineers in the technical knowledge and skills needed for careers in advanced manufacturing and sustainable mining technology.

In my free time, I like gardening and other outdoor activities. They help me relax and stay creative. I also love engaging with innovation communities and reading about new technologies.

Zhengyi’s top tips

1. Try to get as much hands-on experience as possible. This could be through your own projects, work experience or internships with local manufacturers and engineers, or engineering events and competitions. These will build your skills and network.

2. Seek guidance from mentors and stay informed about industry trends.

3. Enjoy the process. The journey is just as important as achieving your end goals.

Do you have a question for Zhengyi?

Write it in the comments box below and Zhengyi will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)

Discover how materials scientists and engineers design and test new materials:

futurumcareers.com/living-in-a-material-world-the-importance-of-materials-science-and-engineering

0 Comments