How can robots help us walk?

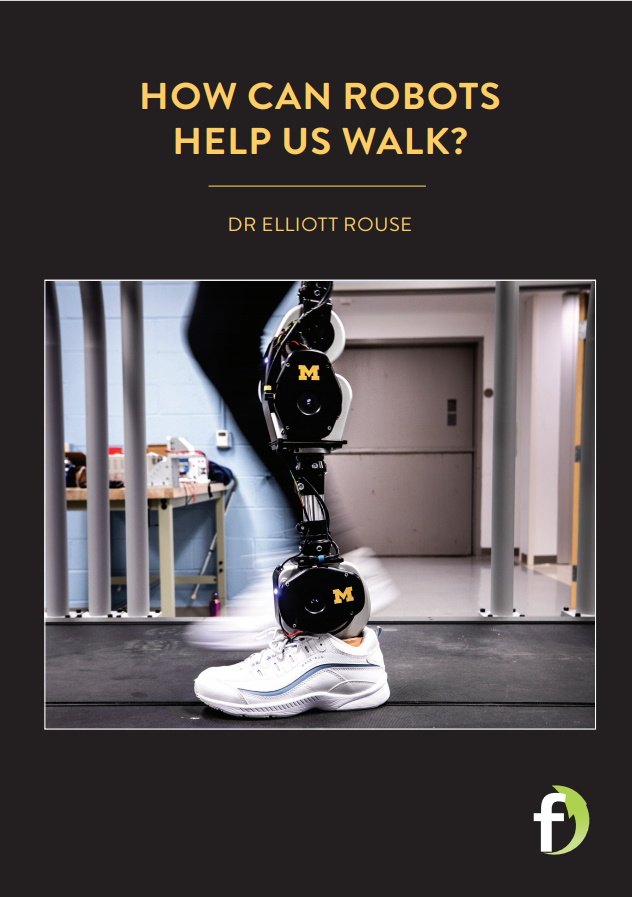

Prosthetic legs have enabled thousands of people with a disability walk, but artificial limbs can be stiff and uncomfortable to use. Dr Elliott Rouse, of the University of Michigan, is using robotics to help us understand how people walk and develop new prostheses that can react and adapt to our motion

TALK LIKE A BIOMEDICAL ENGINEER

PROSTHESIS – an artificial body part

AMPUTATION – removal of a limb

BIONICS – the science of using ideas from biological systems to solve engineering problems. Bionic parts are artificial body parts that combine electronic and mechanical devices

BIOMECHANICS – the study of how living systems move and function

EXOSKELETON – in robotics, an exoskeleton is a wearable electromechanical device. They are often used to enhance performance, such as to help someone lift objects heavier than they normally could

LOCOMOTION – motions such as walking, running or climbing stairs

Robots make our lives easier in so many ways. For instance, they help us build cars, explore dangerous environments, and can even help us move our bodies. Iron Man might be a fictitious character, but bionic limbs that can adapt to different types of movement in the human body are an exciting new reality.

Dr Elliott Rouse is an assistant professor at the Neurobionics Lab in the University of Michigan in the US. He is also a biomedical and mechanical engineer whose pioneering research aims to help people with a disability and/or amputation. His Neurobionics Lab is devoted to overcoming many of the problems with conventional protheses and exoskeletons by understanding more about how we move and developing robotics technologies that leverage this.

WHAT ARE THE PROBLEMS WITH PROTHESES?

Take a conventional prosthetic leg, for example. Leg prostheses have enabled many people who have lost part or all of their leg to regain the ability to walk without any need for crutches. Conventional prosthetic feet are usually made from carbon composite springs that store and return energy to push the wearer forward while walking. They are shaped like feet but are typically very stiff. This stiffness cannot be changed, which can be fine for walking but can make it more difficult if the wearer wants to do different kinds of activities, like moving from walking to running, or ascending and descending stairs.

When we walk, we burn energy from food to fuel the movement of our bodies. How much energy is needed to make a step depends on how efficient that conversion process is. If a protheses is poorly designed for a particular type of movement, the storage and return of energy in the carbon composite springs will also be poor, making the movement more tiring, in addition to more unstable and asymmetric.

WHAT DOES THE BIONIC LEG DO?

To solve these problems, Elliott and his team have developed an ‘open source bionic leg’. This is a protheses that can be used as a bionic knee or ankle joint, or both. It is freely available to the research community, i.e., open source. Unlike a normal protheses, Elliott’s bionic leg is fully robotic and can be controlled using a small computer. Not only that but sensors in the leg give information about the forces at work, which scientists can use to understand how the joint behaves during different types of movement, and develop mathematical instructions called ‘control systems’ that tell the leg how to move.

Excitingly, many different research groups and students around the world have been involved in this project. Students from Georgia Tech, USA, and India have been writing new software to learn more from the data collected from the bionic leg. The leg has also been designed to be low-cost, compact and easy to manufacture, meaning it is easier for innovators to use it as a test device to trial their ideas.

Elliott has been using this bionic leg to better understand how humans walk and as a test system for designing new bionic protheses. Although many of us do not think about it when we walk, walking is a complicated movement and understanding the biomechanics of this process has challenged researchers for years. Through his research, Elliott realised that there is a longstanding misconception about how joint stiffnesschanges during walking.

WHAT ARE THE NEW DESIGNS?

Based on this new knowledge, Elliott and his team have developed a new type of ankle-foot protheses called the VSPA foot that can vary its stiffness from step to step. VSPA stands for variable stiffness prosthetic ankle-foot and walking with this VSPA foot should feel much more natural for the wearer when compared to conventional foot prostheses. Licensed by WillowWood, a major prostheses manufacturer in the US, it also heralds the development of more advanced protheses that can respond to changes in movement, just like our bodies do. These new protheses are much more flexible and efficient in terms of energy use, as well. Elliott is now working with a company to commercialise the VSPA foot and make it available to more people who need protheses.

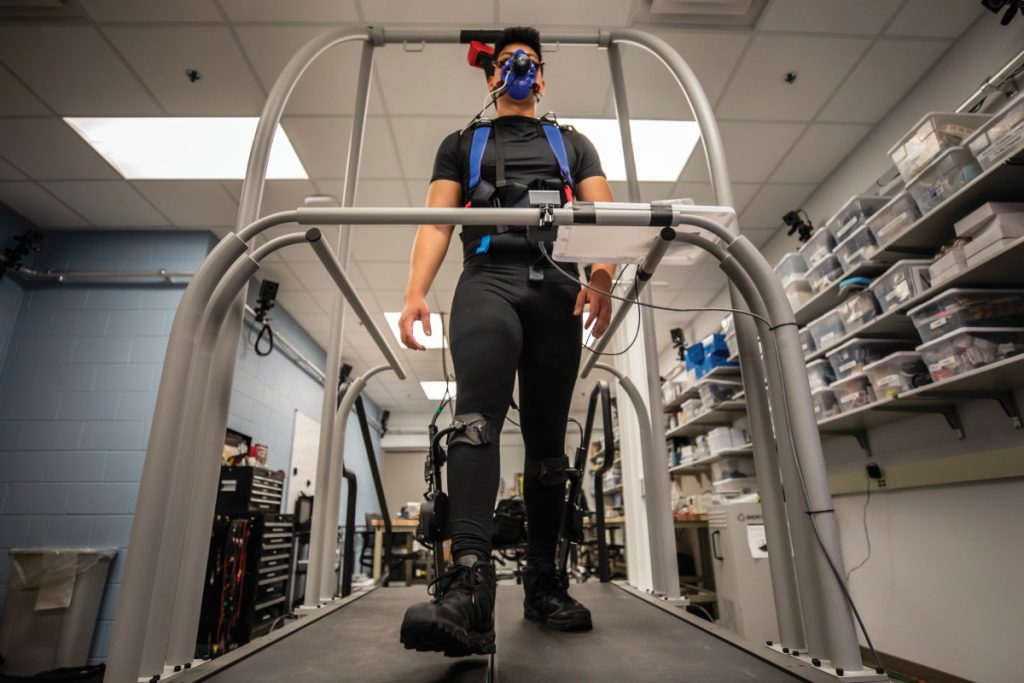

Importantly, though, Elliott’s work is already helping to increase our understanding of biomechanics and make a difference to the lives of people with amputation and others living with a disability. Elliott is also hoping to design new robotics technologies and exoskeletons for people who have had a stroke to assist them with their mobility. “We seek to address fundamental questions about how the nervous system regulates leg mechanics during locomotion”, explains Elliott. “To this end, we’re essentially reverse-engineering the human neuromotor system, which lets us use this information as a set of instructions for developing transformative assistive technologies. We’re also studying the science of human perception and the role of preference in the design and control of wearable robotic systems.”

DR ELLIOTT ROUSE

DR ELLIOTT ROUSE

Assistant Professor, University of Michigan, USA

FIELD OF RESEARCH: Biomedical Engineering, Mechanical Engineering, Robotics

RESEARCH PROJECT: Using robotics to understand how humans walk and design better protheses

FUNDER: National Science Foundation

National Institutes of Health

US Department of Defense

D Dan and Betty Kahn Foundation

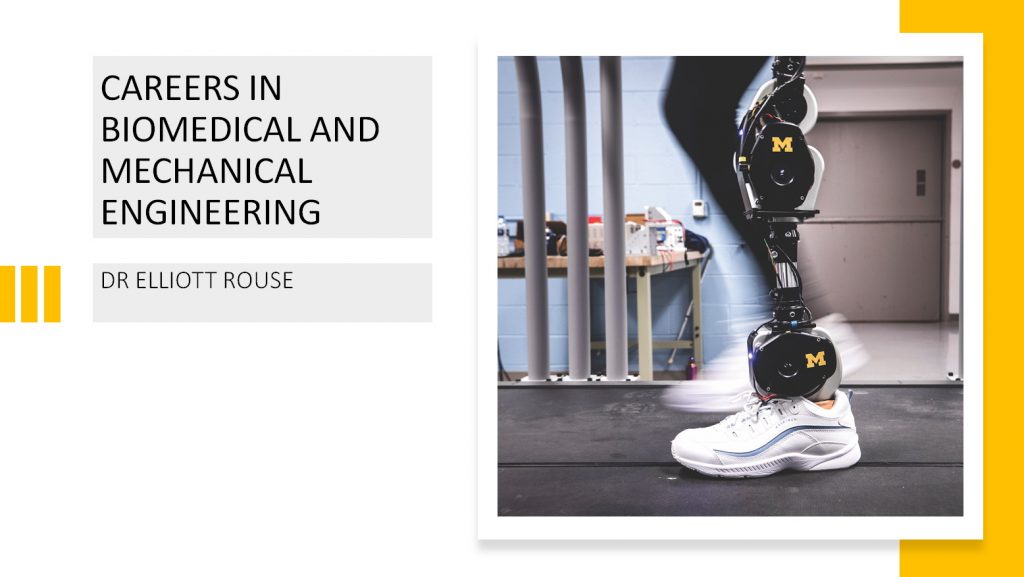

According to the University of Michigan, biomedical engineering is, “the application of the life sciences and engineering principles to bridge the gap between medical technology and medicine in practice”. Mechanical engineering, on the other hand, is, “the application of physical mechanics to build the technology of the future”. Mechanical engineers design and build vital technologies from cars to planes, robots and prosthetics. Biomedical engineers use their expertise to develop medical technologies for all areas of patient care, from diagnostics to treatment and recovery.

Elliott’s work is the perfect example of research at the cutting-edge of biomedical and mechanical engineering. He explains the meaning of neurobionics – the name of his lab – and what the future holds for these exciting fields. “Neurobionics refers to my specific research group, rather than a discipline. It encompasses the idea of studying how the nervous system regulates the mechanics of gait [a particular way of walking] and using this information to develop innovative wearable robotic systems.”

Reference

https://doi.org/10.33424/FUTURUM105

Neurobionics team photo in the demonstration area at Amazon’s re:MARS conference in June 2019. The demonstrations showed the Open Source Bionic Leg and let attendees physically interact with it and learn about the leg’s control strategies.

TALK LIKE A BIOMEDICAL ENGINEER

PROSTHESIS – an artificial body part

AMPUTATION – removal of a limb

BIONICS – the science of using ideas from biological systems to solve engineering problems. Bionic parts are artificial body parts that combine electronic and mechanical devices

BIOMECHANICS – the study of how living systems move and function

EXOSKELETON – in robotics, an exoskeleton is a wearable electromechanical device. They are often used to enhance performance, such as to help someone lift objects heavier than they normally could

LOCOMOTION – motions such as walking, running or climbing stairs

Robots make our lives easier in so many ways. For instance, they help us build cars, explore dangerous environments, and can even help us move our bodies. Iron Man might be a fictitious character, but bionic limbs that can adapt to different types of movement in the human body are an exciting new reality.

Dr Elliott Rouse is an assistant professor at the Neurobionics Lab in the University of Michigan in the US. He is also a biomedical and mechanical engineer whose pioneering research aims to help people with a disability and/or amputation. His Neurobionics Lab is devoted to overcoming many of the problems with conventional protheses and exoskeletons by understanding more about how we move and developing robotics technologies that leverage this.

WHAT ARE THE PROBLEMS WITH PROTHESES?

Take a conventional prosthetic leg, for example. Leg prostheses have enabled many people who have lost part or all of their leg to regain the ability to walk without any need for crutches. Conventional prosthetic feet are usually made from carbon composite springs that store and return energy to push the wearer forward while walking. They are shaped like feet but are typically very stiff. This stiffness cannot be changed, which can be fine for walking but can make it more difficult if the wearer wants to do different kinds of activities, like moving from walking to running, or ascending and descending stairs.

When we walk, we burn energy from food to fuel the movement of our bodies. How much energy is needed to make a step depends on how efficient that conversion process is. If a protheses is poorly designed for a particular type of movement, the storage and return of energy in the carbon composite springs will also be poor, making the movement more tiring, in addition to more unstable and asymmetric.

WHAT DOES THE BIONIC LEG DO?

To solve these problems, Elliott and his team have developed an ‘open source bionic leg’. This is a protheses that can be used as a bionic knee or ankle joint, or both. It is freely available to the research community, i.e., open source. Unlike a normal protheses, Elliott’s bionic leg is fully robotic and can be controlled using a small computer. Not only that but sensors in the leg give information about the forces at work, which scientists can use to understand how the joint behaves during different types of movement, and develop mathematical instructions called ‘control systems’ that tell the leg how to move.

Excitingly, many different research groups and students around the world have been involved in this project. Students from Georgia Tech, USA, and India have been writing new software to learn more from the data collected from the bionic leg. The leg has also been designed to be low-cost, compact and easy to manufacture, meaning it is easier for innovators to use it as a test device to trial their ideas.

Elliott has been using this bionic leg to better understand how humans walk and as a test system for designing new bionic protheses. Although many of us do not think about it when we walk, walking is a complicated movement and understanding the biomechanics of this process has challenged researchers for years. Through his research, Elliott realised that there is a longstanding misconception about how joint stiffnesschanges during walking.

WHAT ARE THE NEW DESIGNS?

Based on this new knowledge, Elliott and his team have developed a new type of ankle-foot protheses called the VSPA foot that can vary its stiffness from step to step. VSPA stands for variable stiffness prosthetic ankle-foot and walking with this VSPA foot should feel much more natural for the wearer when compared to conventional foot prostheses. Licensed by

WillowWood, a major prostheses manufacturer in the US, it also heralds the development of more advanced protheses that can respond to changes in movement, just like our bodies do. These new protheses are much more flexible and efficient in terms of energy use, as well. Elliott is now working with a company to commercialise the VSPA foot and make it available to more people who need protheses.

Importantly, though, Elliott’s work is already helping to increase our understanding of biomechanics and make a difference to the lives of people with amputation and others living with a disability. Elliott is also hoping to design new robotics technologies and exoskeletons for people who have had a stroke to assist them with their mobility. “We seek to address fundamental questions about how the nervous system regulates leg mechanics during locomotion”, explains Elliott. “To this end, we’re essentially reverse-engineering the human neuromotor system, which lets us use this information as a set of instructions for developing transformative assistive technologies. We’re also studying the science of human perception and the role of preference in the design and control of wearable robotic systems.”

DR ELLIOTT ROUSE

DR ELLIOTT ROUSE

Assistant Professor, University of Michigan, USA

FIELD OF RESEARCH: Biomedical Engineering, Mechanical Engineering, Robotics

RESEARCH PROJECT: Using robotics to understand how humans walk and design better protheses

FUNDER: National Science Foundation

National Institutes of Health

US Department of Defense

D Dan and Betty Kahn Foundation

According to the University of Michigan, biomedical engineering is, “the application of the life sciences and engineering principles to bridge the gap between medical technology and medicine in practice”. Mechanical engineering, on the other hand, is, “the application of physical mechanics to build the technology of the future”. Mechanical engineers design and build vital technologies from cars to planes, robots and prosthetics. Biomedical engineers use their expertise to develop medical technologies for all areas of patient care, from diagnostics to treatment and recovery.

Elliott’s work is the perfect example of research at the cutting-edge of biomedical and mechanical engineering. He explains the meaning of neurobionics – the name of his lab – and what the future holds for these exciting fields. “Neurobionics refers to my specific research group, rather than a discipline. It encompasses the idea of studying how the nervous system regulates the mechanics of gait [a particular way of walking] and using this information to develop innovative wearable robotic systems.”

WHAT DOES THE FUTURE LOOK LIKE FOR BIOMECHANICAL SCIENCE?

It’s a super exciting time for our lab and the field as a whole. Our work on the open source leg is being adopted by groups around the world. Our VSPA foot is being commercialised and may truly change the quality of life for people with leg amputations. We’re advancing a new and potentially transformative approach for the design and control of exoskeletons and robotic prostheses based on user preference.

Finally, we’re studying people’s ability to perceive changes in metabolic rate, and developing new and creative metrics of success for modern exoskeletons. Over the next several years, we’ll continue to study these important areas, and will expand our approaches as we learn more about these topics.

WOULD YOU RECOMMEND A CAREER IN BIOMECHANICAL SCIENCE?

My answer is a resounding ‘yes’, but this industry is a little different than most. In the development of bionic systems, advanced research and design is generally conducted within academia and funded by government agencies. This is different from other areas of engineering, where research and development can be conducted primarily within companies.

If someone is interested in this field, their best bet is to get involved in a laboratory at their university – this could be as a student, staff engineer, therapist or volunteer. There are many fantastic universities with great wearable robotics researchers, and most would be happy to learn of people who are interested in their work.

HOW DID ELLIOTT BECOME A BIOMEDICAL AND MECHANICAL ENGINEER?

WHAT DID YOU WANT TO BE WHEN YOU WERE YOUNGER?

My career path during college provided a unique set of experiences that culminated in a passion for research and development of technologies to help people with disabilities. As an undergraduate student, I worked full time for a professional autoracing team. At that time, I thought this was the most amazing job possible but, as the years went on, I longed to make a greater impact on people, and particularly those with disabilities. So, the summer before my last year at university, I took a break from autoracing to join a summer internship programme at the Cleveland Clinic’s biomedical research division, and I fell in love with biomedical research and development.

I then began researching graduate schools and remember seeing a press conference from Dr Todd Kuiken at Northwestern University/Rehabilitation Institute of Chicago. He had developed a surgery technique to re-wire people’s nerves to control advanced prostheses, and I was really excited about the prospect of working with him. I got in contact with Dr Kuiken and was accepted onto the MS programme at Northwestern University. So began a long path to obtain a doctorate and eventually study technologies that will change peoples’ lives.

WHO OR WHAT INSPIRED YOU TO GET INTO MECHANICAL ENGINEERING?

Honestly, I didn’t know much about mechanical engineering when I went into my undergraduate studies. I pretty much chose mechanical engineering because my twin brother and friends were pursuing mechanical engineering, and I knew I was passionate about cars. When I began to study more advanced mathematics and physics, I was fascinated. The course that probably had the greatest effect on me was a class that studied system dynamics, which discussed the tools of modelling physical systems. Upon graduation, I realised I enjoyed system dynamics, and that I wanted my work to help people overcome physical challenges.

Once I began looking into rehabilitation and biomechanics, I felt drawn to this area of study because it held the potential to impact people in the near term (which is uncommon in academic research), and because there are many important and challenging problems to solve.

WHAT DO YOU LOVE MOST ABOUT THE WORK YOU DO?

That is a tough question! There are three main things I love about what I do. 1) I love teaching and mentoring students. The world of engineering has so many interesting things to discuss, and it’s wonderful to be able to share these concepts with bright young students. In addition, I care deeply for the graduate students I mentor in my research group and enjoy helping them grow personally and professionally. 2) I thrive on independence. I love being able to set the vision for my research group and study technical challenges I find most meaningful and interesting. And 3) I’m passionate about changing the lives of people in the near term, especially those with disabilities. There’s something really special about when an experimental participant tries the technologies we develop, and they smile and discuss what they like and dislike, and how they could see their life changing. These experiences remind me of the meaning of our work and keep me refreshed; they are as fulfilling as they are energising.

WHAT DO YOU KNOW NOW THAT YOU WISH YOU’D KNOWN WHEN YOU WERE YOUNGER?

Oftentimes, undergraduate students will visit me and discuss their career situation as they determine their next step. Usually, they’re anxious and sometimes feel lost. They seem to feel the pressure of finding the right thing to do with their life, and if they don’t figure it out, they’ve somehow made a mistake or sabotaged themselves. I think that way of thinking about the future puts too much pressure on someone – life doesn’t really work that way. I started with the idea that I enjoyed the study of system dynamics and wanted to help people. I recommend that students zoom out and think about what gets them excited. Begin there and search exciting options that they find meaningful.

HOW TO BECOME A BIOMEDICAL OR MECHANICAL ENGINEER

There are several routes into biomedical and mechanical engineering, including apprenticeships, but the most common route is a degree at university. This is particularly important if you want to go into a research-based career like Elliott.

• Many labs are happy to host work experience students, so get in touch. For example, Elliott and his team have several projects listed in their website: https://neurobionics.robotics.umich.edu

• The University of Michigan lists a number of exciting engineering outreach opportunities on their website: https://ceo.umich.edu

• The average salary for a biomechanical engineer is $65,779, which can rise to an $80,000 or $100,000 starting salary with a doctorate

PATHWAY FROM SCHOOL TO BIOMEDICAL OR MECHANICAL ENGINEER

Elliott says, “At the high school level, I would say take advantage of calculus and advanced physics courses. If your school offers a robotics club, get involved. Tinker with things, learn to code and play with basic microprocessors (e.g. Arduino) and single board computers (e.g. Raspberry Pi). At the undergraduate level, personally, I’d recommend majoring in robotics or mechanical or electrical engineering. These degrees provide a little more technical depth.”

Maths, physics, chemistry and engineering are recommended subjects for both biomedical and mechanical engineering.

More information about the different types of engineering degrees can be found here: https://typesofengineeringdegrees.org

ELLIOTT’S TOP TIPS FOR STUDENTS

01 Think about the types of problems you like to solve and start there. Search for broad opportunities that overlap with those types of challenges and begin looking. Take the next step and perform as strongly as you can. Then use that experience to level up.

02 Don’t be afraid to change your path as you learn about your passions. In fact, this often leads to cross disciplinary skillsets that you can leverage throughout your career. I began as an autoracing mechanic, and am now a professor studying bionic systems, but I still use my ‘hands on’ mechanical skills every day.

03 When working in school or in the workplace, be sure you convert your effort into tangible results. This is important for showing productivity, and demonstrating your abilities when you want to take your next step.

04 Don’t put too much pressure on yourself – start with an idea you really care about and see where it takes you!

Do you have a question for Elliott?

Write it in the comments box below and Elliott will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)