How can we detect and prevent brain injuries?

Inside your skull sits your brain, an incredible computer that controls everything you do. The skull does its best to protect our brains from injury, but, sometimes, it is not enough. Professor Christian Franck, from the University of Wisconsin-Madison in the US, leads the PANTHER programme, researching new ways of detecting and preventing traumatic brain injuries.

TALK LIKE A BIOMECHANICAL ENGINEER

Asymptomatic — when there are no detectable indications (symptoms) that a person is suffering from a condition

Induced hypothermia — the deliberate reduction in temperature of a patient

Neurodegenerative — when cells in the brain or nervous system stop working or die

Strain rate — the speed at which something is deformed

Traumatic brain injury (TBI) — when the brain becomes damaged as the result of an impact or shock to the head

We experience the world through our brains. Everything that you see, hear, taste, touch, smell, think and imagine has passed through the inside of your head. In there, underneath your thick, bony skull, lives a squidgy, pink mass that is home to an incredibly complex network of roughly 86 billion neurons. This network of neurons is in control of everything that we think, feel and do.

As well as being wildly intricate and vital to our continued existence, our brains are also exceedingly delicate. Although our skulls do a stellar job at protecting them, it is all too easy for our brains to become damaged. Even something as simple as being hit on the head by a ball can have serious consequences.

If you have ever had a concussion, you will know how unpleasant it can be. Whether you fell off your bike, hit your head in the playground or collided with someone playing football, the chances are that your concussion came from a relatively minor incident. Even so, concussion should not be taken lightly. You only have one brain, so it is important to take care of it!

Understanding how best to protect our brains can be a tricky business, not least because brain injuries can be hard to detect. Many mild brain injuries can be asymptomatic, meaning that there may be no outward or obvious signs that any damage has been done. Even so, these injuries can lead to significant problems later on, so it is important to identify them.

It might surprise you that it is the field of mechanical engineering that could offer the answers to the questions related to traumatic brain injuries (TBIs). Professor Christian Franck, from the Department of Mechanical Engineering at the University of Wisconsin-Madison, is working on a programme that he hopes will improve the prevention and detection of TBIs. Called PANTHER, this programme relies on a large interdisciplinary team and uses the latest advances in experimental mechanics and molecular cell biology to study TBIs and to develop new ways of preventing them.

Why is it so important to detect asymptomatic brain injuries?

If asymptomatic brain injuries are left untreated, they can lead to serious neurodegenerative diseases such as Alzheimer’s, Parkinson’s and dementia. Detecting brain injuries early can help to lower the risk of a patient developing any of these diseases.

Asymptomatic brain injuries can also lead to mood disorders such as depression and suicidal tendencies. As mental health disorders are common, it can be hard to spot when a disorder is related to a brain injury. As a result, patients are at risk of being given the wrong diagnosis and treatment, which can lead to further complications.

Young people who have sustained an asymptomatic head injury may find school difficult. They may struggle to concentrate in class or focus on an exam. This can destroy a student’s self-confidence and create challenges that may stay with them throughout their educational journey. Identifying whether an asymptomatic head injury has caused these issues can help students get the support they need.

How does PANTHER study brain injuries?

Christian and his team of researchers use the latest technology in their experiments. Participants wear cutting-edge, flexible sensors which track how their heads move in different situations. Data from these sensors is fed into a computer model which then simulates how the brain moves in response to particular types of head movement. Using knowledge of how physics and biology influence the brain, Christian’s team can analyse the output from this computer model to understand which head movements are likely to result in injury.

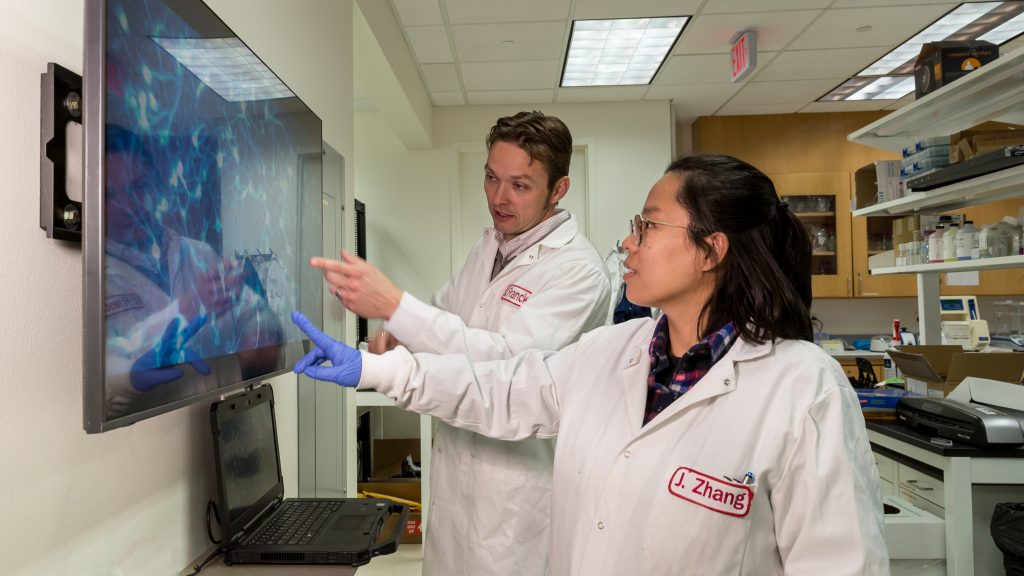

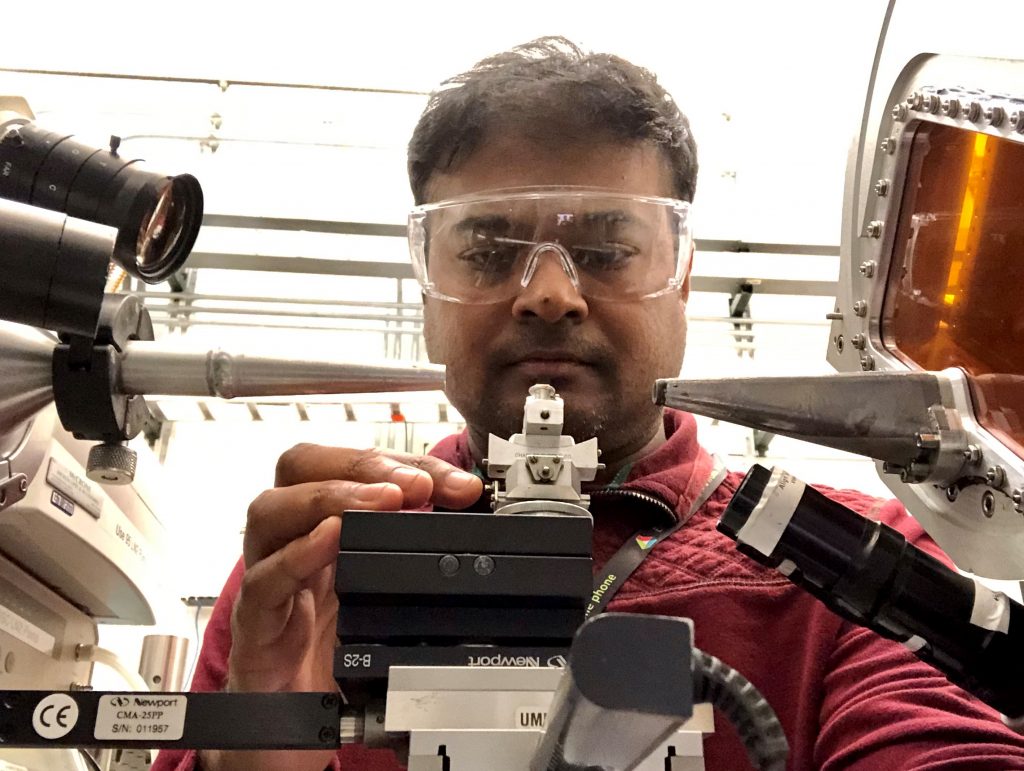

By using innovative advances in 3D imaging and microscopy, Christian and his team can take a closer look at what is really happening. “We are now able to recreate the kind of physical deformations and impacts that the head and brain might experience during a TBI at the cellular scale,” explains Christian. By using advanced experimental techniques, the team can track molecular changes in brain cells that are responding to injury and get a much clearer picture of what happens to the brain after a TBI.

You will read more about the different elements that go into the PANTHER programme – biomechanics, the mechanics of materials, and sensing and motion – over the next few pages.

How can PANTHER help to prevent brain injuries?

The lab-based, experimental approach that Christian uses to study TBIs lends itself well to testing potential therapies and treatments. For example, his team has conducted experiments which show that cooling the brain down, sometimes known as induced hypothermia, is an effective way of preventing further injury to the brain in the aftermath of a TBI.

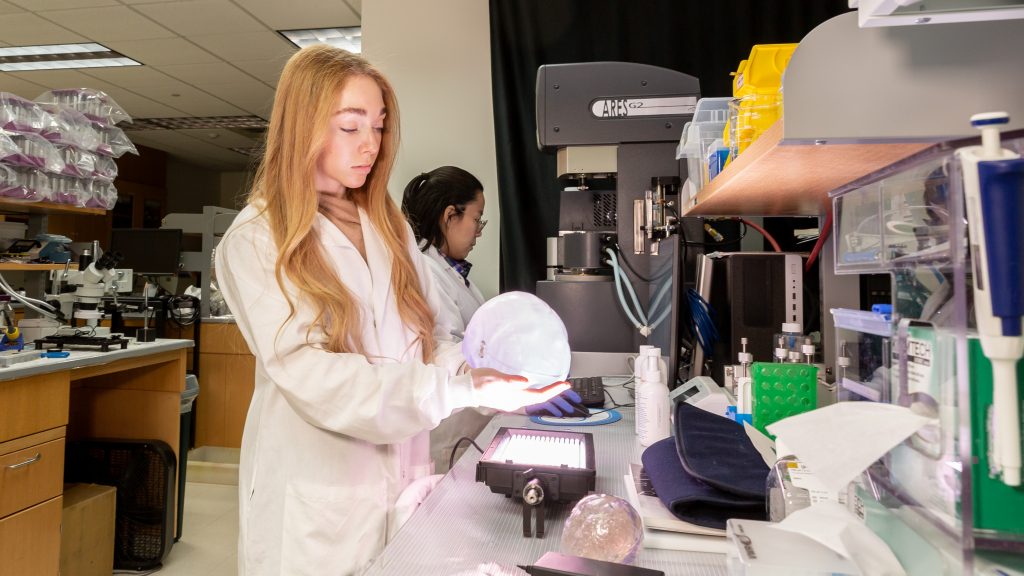

Christian’s research can also support the development of new protective materials. These materials can be designed based on his detailed understanding of the physical stresses that can damage brain tissue, such as the amount and speed of tissue stretching. The new materials that are produced can be tailored specifically to reduce the impact of these particular stresses. “These materials can then be integrated into new helmets and helmet designs and be provided to consumers for the military, sports and recreation,” says Christian.

In addition to creating new safety equipment, Christian’s team also hopes to prevent brain injuries through the development of better safety guidelines. PANTHER’s research into the root causes of brain injuries will allow the team to inform and update safety protocols to keep people out of harm’s way.

What makes studying brain injuries so challenging?

“The most formidable challenge remains the brain itself,” says Christian. “Understanding the physical and biological response of over a billion cells requires a lot of careful analysis, dedication and a diverse, focused team!”

There are 25 researchers working in the PANTHER programme, with expertise ranging from mechanical engineering to cell biology and neuroscience. Whilst having such a large, diverse team is exciting, it can present its own challenges. Maintaining clear communication between all of the researchers can be difficult, especially as the programme continues to grow.

What successes has the PANTHER programme had so far?

The PANTHER programme has enabled important research into brain injuries that are caused by explosions or blasts. Christian’s team conducted experiments in which brain tissue was subjected to the kind of intense deformations that would be experienced during an explosion. The team was then able to quantify the damage caused to the brain in such situations for the first time.

The PANTHER programme has also helped to develop a unique system for categorising advanced helmet liner materials based on their properties and how they respond in different situations. This system can hopefully be used to inform and improve the design of new helmets.

What is next for the PANTHER programme?

“There are many next steps as they are still so many unanswered questions,” says Christian. For example, one of their next research projects involves looking at whether male and female brains respond to injury in different ways. But they are not just looking at more research projects. Within the next two years, Christian hopes that PANTHER will get their first ‘brain-protective’ helmets on to the market. In doing so, he hopes that they can provide protection both to military personnel and civilians alike.

Professor Christian Franck

Professor Christian Franck

Department of Mechanical Engineering, University of Wisconsin-Madison, USA

Fields of research: Mechanical Engineering, Biomedical Engineering

Research project: Investigating the cellular processes that underly brain injuries to find new ways of detecting and preventing them

Funders: US Office of Naval Research (ONR), Bjorn Borgen Professorship

About biomechanics

Much of the research conducted in the PANTHER programme involves biomechanics. This is an area of science that studies the physics of living things, from single cells to whole organisms. Christian and his team have been using biomechanics to study what happens to brain cells when they are subject to the forces of a traumatic brain injury (TBI).

How do brain cells respond to traumatic brain injuries?

Through PANTHER, Christian and his team have discovered that brain cells respond differently to different types of TBI. One of the key factors is the speed at which the injury occurs, and thus the speed at which the brain tissue is deformed, also known as the strain rate.

Reference

https://doi.org/10.33424/FUTURUM410

(© University of Wisconsin-Madison College of Engineering)

(© University of Wisconsin-Madison College of Engineering)

If the strain rate is very slow, on the scale of minutes to hours, the brain tissue can withstand significant amounts of stresses and force. An example of this kind of injury would be a brain oedema, when fluid builds up in, and exerts pressure on, the brain. If the oedema is treated quickly enough, the brain tissue may survive unscathed. Our brain cells are often able to adapt to this kind of gradual change in force, stress or pressure.

When injuries involve a faster strain rate, such as from a fall or a head-to-head collision in football, the brain cells are likely to undergo a process known as secondary injury. For injuries resulting from blasts or explosions, the strain rate is extremely fast and brain cells will undergo primary injury, which is potentially the worst outcome.

What are primary and secondary injuries?

The terms primary and secondary injury describe what happens to brain cells during a TBI. During an extremely fast injury, like an explosion, brain cells will be physically ripped apart, as they are unable to withstand the immense stresses involved. When primary injury occurs, the cells are destroyed immediately, so there is no way to restore them. Recovery from this kind of injury takes a long time and has less favourable outcomes.

Secondary injury mostly occurs when the TBI is slightly slower, as with being hit in the head by a ball. In these cases, cell death is driven more by biochemical responses that play out over the course of a few hours. “The interesting thing is that right before and immediately after a traumatic impact, the tissue and its cells generally look intact and healthy,” says Christian. However, a few hours later, many brain cells may begin to die.

In some cases, the amount of cell death may not be particularly extensive, and the brain may continue to function as normal. The brain has a network of billions of cells which can continue to function properly even if some cells are lost. A person suffering from this type of injury may show no outward symptoms.

However, if these types of injury keep accumulating, the network may become so degraded that it begins to break down. It is vital to detect asymptomatic TBIs because they can build up and, eventually, cause a catastrophic loss of brain function. “This is something we want to prevent at all costs,” says Christian. “Essentially, our goal is to safeguard every brain cell.”

In contrast to primary injuries, secondary injuries have the potential to be treated. There is a short window of about four to six hours in which therapeutic treatments, such as induced hypothermia, could prevent irreversible cell loss.

What tools are used to study these cellular processes?

Christian and his team use ultra-precision devices that subject brain cells to the kinds of forces that they would experience during a TBI. These devices are integrated into state-of-the-art 3D microscopes through which they can track the impact of these forces at a molecular and cellular scale. “This allows us to directly measure and quantify how brain cells respond to physical insult in real time, which is a unique aspect of our work,” explains Christian.

Meet the team

Annalise Daul

Role: MS Student

Fields of study: Mechanical Engineering, Experimental Neuromechanics

Funder: US Office of Naval Research (ONR)

I studied mechanical engineering and aerospace engineering at Oregon State University and graduated during the COVID-19 pandemic. One of my professors recommended that I talk to a colleague of his, Christian Franck, who was looking for a graduate student. He told me my curiosity and desire to learn made me a great candidate. After speaking with Christian, I was convinced that graduate school was the next stepping stone on my path.

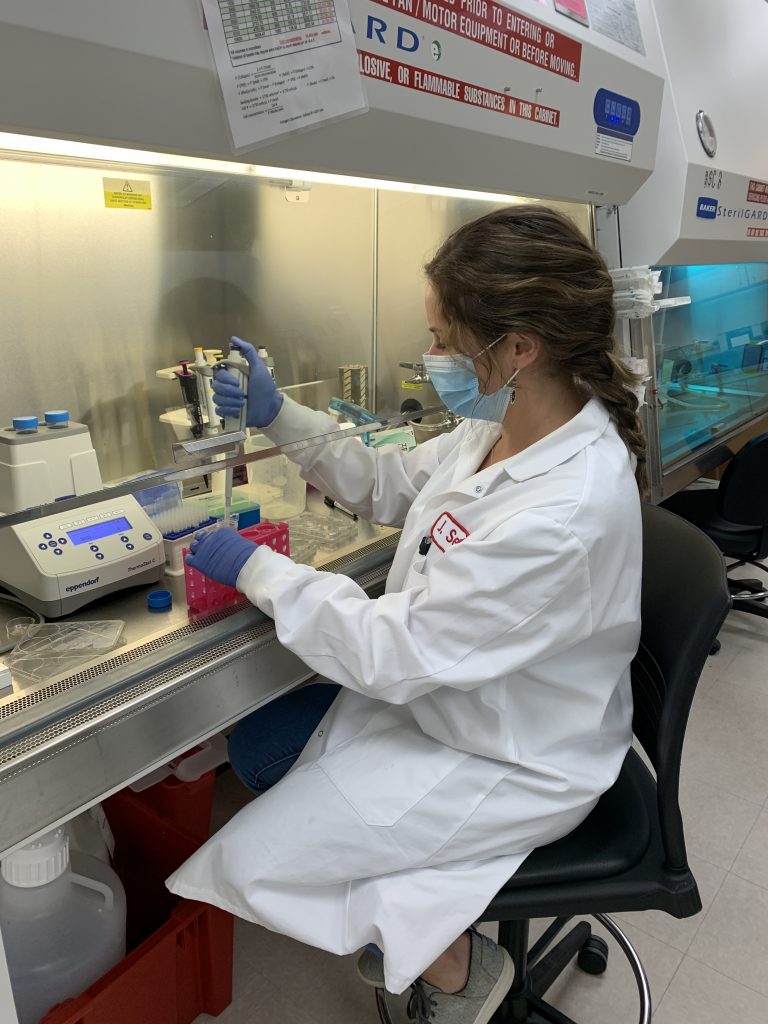

Currently, I am focusing on the effect of mechanical strain and strain rate on neural cells to quantify and develop a TBI threshold curve at the cellular level.

I had a TBI, so I bring a unique perspective to the PANTHER programme, and my background of mechanical engineering allows me to apply the fundamentals of mechanics to neuronal cells.

A typical day consists of classes, coursework and spending time between the office and lab spaces. In the lab, I perform hands-on, experimental tasks, whilst at the office, I focus on analysing data.

Our work is very engaging but can be relentless: research, critical thinking and creativity never stop, so a big challenge has been learning to find a good balance of working hard while also resting. Another challenge is the work itself: biology-based work is sensitive and variable – learning how to pivot from my mechanical engineering experiences to biological applications has been challenging, but rewarding!

Some of the key successes I’ve had so far are establishing key relationships between the mechanics and resulting injury of neural cells. There have not been any eureka moments yet in my research, but I have confidence there will be soon!

I want to make an impact on the lives around me, so I hope to continue to live a life that makes the world a better place.

Annalise’s top tips

1. Question everything and never stop learning.

2. Chase what excites you and don’t doubt yourself.

3. Life rarely follows the path you envisioned for yourself; allow it to happen as it comes, and take advantage of opportunities that pique your interest.

Jamie Sergay

Role: PhD Student

Fields of study: Biomedical engineering, Biomechanics

Funder: Office of Naval Research (ONR)

When choosing to go to graduate school for engineering, I knew I wanted a field that would have a direct, positive impact on people in difficult circumstances. This led me to pursue biomedical research. While studying my undergraduate degree, I decided to take a neuroscience class for my own curiosity and ended up loving it. The Franck Lab’s TBI research was a perfect opportunity to merge my neuroscience interest with my engineering mechanics background.

I am contributing to a newer side of PANTHER by looking at electrical activity in the brain. My biomedical background brings a more biological perspective to a predominantly mechanical group.

In a typical day, you can either find me at my office desk or in the wet lab space. At my desk, I am often reading research articles, planning future experiments or creating presentations. When in the lab space, I am usually taking care of my neural cell cultures or running experiments.

Researching biological materials can sometimes be unpredictable and more difficult to control. The PhD process takes persistence and perseverance; it can sometimes be hard to stay self-motivated during the long programme. However, the successes feel even more rewarding for this.

I have presented my research at numerous mechanics and neuroscience conferences, which helped me make important connections and discover further interests.

I hope to become a university professor and run my own research lab that blends the field of neuroscience and engineering.

Jamie’s top tips

1. Don’t be afraid to make unconventional choices.

2. Reach out to people online who have jobs or research that interest you.

3. Keep trying and exploring; you may get some amazing opportunities.

Simulation

Meet Rika

Dr Rika Carlsen

The Injury Biomechanics Lab, Department of Engineering, Robert Morris University, Pennsylvania

Fields of research: Mechanical Engineering,

Computational Biomechanics

Funder: Office of Naval Research (ONR)

What motivated you to be part of the PANTHER programme?

I really enjoy working on multidisciplinary teams with people who share the same passion as me. Given the complex nature of traumatic brain injury (TBI), we cannot make significant progress by working alone on this research. It takes a team of people working together, bringing expertise from various fields, to make real breakthroughs. The PANTHER programme does just this, bringing together researchers with expertise in many areas such as biology, engineering and medicine. Everyone in PANTHER is passionate about improving our understanding of TBI, and it’s exciting to work with such a dynamic and collaborative team on this important research.

Which three words best describe a ‘typical day’ for you on this research?

Impactful, engaging and collaborative.

What simulations do you produce, and how?

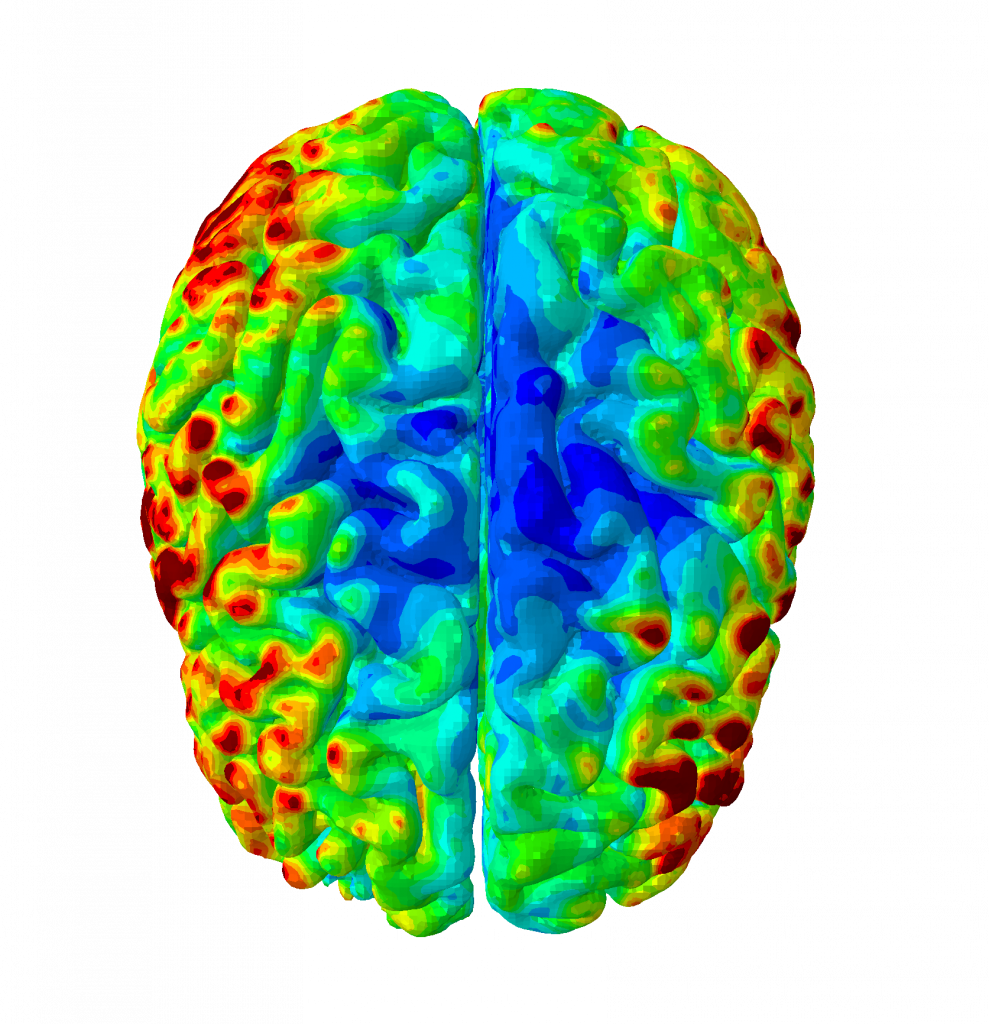

We build detailed computational head models directly from a person’s medical imaging data, such as magnetic resonance images (MRI) or computed tomography (CT) scans. We use several different software programs and codes to generate these models. We often refer to these models as ‘human digital twins’, i.e., a digital representation of a person. These digital twins are used with measured sensor data from real-world head impacts to run a computational simulation of the impact event and predict the risk of brain injury.

What do these simulations reveal about what happens at the cellular level?

Since we cannot see in real-time what happens to a person’s brain when they sustain a TBI, we turn to computational models to get a picture of what happens inside the head during an impact event. Brain tissue is very compliant, much like gelatine, and can undergo large deformations when the head is impacted. Computational models can reveal the extent to which the tissues deform and how neurons in our brain might become damaged. We have learnt that when neuronal cells are stretched too much and too fast, they can become permanently damaged, which can lead to brain injury.

What do these computational models allow you to predict?

The ultimate goal is to use these computational models to predict the risk of brain injury. These computational models can also be used to identify those head loading conditions that cause the most injury. This information can, in turn, be applied to guide the design of next-generation protective equipment or to develop new safety standards.

What key successes have you had so far?

Some of our major successes include the integration of anatomical details from high resolution medical imaging into our computational models and the use of wearable sensor data as inputs into our models. As medical imaging and sensing technology has improved, it has allowed us to increase the accuracy of our models.

What are the next steps for your research?

We are moving toward real-time estimates of injury. We can imagine a future where all protective equipment, such as helmets, will have embedded sensors in them. The sensor data can then be used as inputs into models that will be able to predict the risk of brain injury any time the head is impacted. This information could potentially be used in the future to diagnose injury, inform treatment or guide ‘return-to-play’ decision-making in sport to prevent permanent, long-term damage to the brain.

What are your proudest career achievements?

Being the first in my family to get a four-year bachelor’s degree was an achievement in itself. When I was younger, I never imagined that I would go on to get a graduate degree, let alone a PhD. I’m so grateful each and every day to be able to do the exciting and impactful work that I do.

Rika’s top tip

Continue to seek out opportunities to challenge yourself and gain new knowledge and skills. When you challenge yourself, you are going to fail from time to time. I certainly have, but each one of those failures was a learning opportunity. Don’t let fear of failure prevent you from trying new things and getting to where you want to go in the future.

Measuring inputs

Meet Joseph

Dr Joseph Andrews

Head Sensing Lead, University of Wisconsin-Madison

Fields of research: Mechanical Engineering, Electrical and Computer Engineering

Funders: US Department of Defense (DOD), US National Science Foundation (NSF), US Department of Agriculture (USDA), Wisconsin Alumni Research Foundation, Discovery To Product

What motivated you to be part of the PANTHER programme?

One of the key motivations for my work is developing light-weight sensing technologies for wearable applications. Through PANTHER, I can work with experts across many disciplines to design, build and validate wearable sensing technologies to help us understand brain injury at a deeper level.

What types of sensors do you use in this research, and how do you make them?

We use a methodology called Flexible Hybrid Electronics (FHE). We combine traditional microelectromechanical accelerometers with flexible electronic components and sensors to enable system level integration within a wearable form. We can either make prototypes in the lab through printing, which allows for a high degree of customisation and immediate turn-around, or we can use flexible, printed circuit board technology to enable more robust flexible systems.

What data do your sensors provide?

Currently, we are working on two sensing technologies. One enables kinematic (motion) measurements through multiple acceleration sensors. This allows us to understand impact events and, ultimately, recreate the scenario in simulation. We are also working on developing pressure/force sensors. These large-area pressure sensors can allow us to understand what led to the accelerative event, providing information to help us better understand the injury scenario.

What are these data revealing about what happens in the brain in a brain injury?

The sensor data will allow us to have a high-fidelity recreation of the event that led to injury. This will reveal to us many of the nuances related to injury in terms of the variables associated such as impact magnitude, impact direction, rotational components and others.

What key successes have you had so far?

We have successfully developed a fully flexible sensing system that offers eight 3-axis accelerometers and weighs only five grams. We have demonstrated the ability for the system to recreate kinematics within head model drop tests and are excited to continue development.

What are the next steps for your research?

Currently, we are working on making our technology field deployable. This includes tackling challenges related to comfort and battery consumption.

What are your proudest career achievements?

There are two things that make me proud in my career. Seeing technology from the lab translate to real-world impact and observing my students’ success. The former I experienced during my PhD, when a tyre sensing technology I helped invent enabled a start-up company. The latter I see in small ways every day, but most significantly when students graduate.

Joseph’s top tips

1. Try to find a mentor in your field and work with them.

2. Be curious and outgoing in your discussion, and learn from those around you.

Mechanics of Advanced Materials

Meet Theva

Professor Ramathasan Thevamaran

Departments of Mechanical Engineering, Engineering Physics, and Materials Science and Engineering, University of Wisconsin-Madison

Field of research: Mechanical Engineering

Funders: US Army Research Office (ARO), Office of Naval Research (ONR), US Department of Energy (DOE), US National Science Foundation (NSF), Wisconsin Alumni Research Foundation, US National Aeronautics and Space Administration (NASA)

What motivated you to be part of the PANTHER programme?

The PANTHER programme brings together researchers from biomechanics to mechanics of materials and material design to tackle a longstanding multidisciplinary challenge of tackling traumatic brain injury (TBI). My lab focuses on developing a fundamental

understanding of process-structure-property-function relations in materials. We exploit that understanding to create innovative new materials with superior properties and functionalities for extreme environments, making us a perfect fit for PANTHER.

Why is developing a fundamental understanding of process-structure-property- function so vital?

We humans build knowledge by interrogating ourselves and the environment around us with curiosity to learn how nature functions. We also have an urge to get more efficient at performing certain functions important for our day to day lives, as well as to advance as an intelligent species – which led us to engineering! An advancement merely by trial by error can get us only so far. It’s important to understand the fundamentals, in detail from the bottom up, so we can engineer new materials in unprecedented ways.

What innovations are enabling you to develop next-generation protective materials?

We often work with design and experimental methods to learn about a complex material we fabricate – for which there aren’t readily available computational models. We occasionally learn unusual process-structure-property relations that may emerge when we fabricate and test these materials. Then we exploit such relations in ways that can offer better protective functionalities.

Depending on the nature of the application, we engineer new protective materials starting with components that have exceptional intrinsic properties – for example, carbon nanotubes and certain polymers – and build them up across different length scales, from a few nanometres to several centimetres, with efficient structural design rules that yield superior properties. We also focus on making these materials lightweight yet robust.

How do you model material response?

Some of the material systems we study exhibit properties that are not previously known or not well understood, so a computational or theoretical model may not already exist. We often develop our own models, taking into account the fundamental physical mechanisms we identify through our experiments on these materials. We also work with our collaborators in theoretical physics and mechanics to develop models.

Have there been any eureka moments during this research?

Absolutely! These moments are the ones that keep us motivated to reach new frontiers. The most recent eureka moment in the PANTHER programme was when we discovered an unusual process-structure relation that emerged when we synthesised vertically aligned carbon nanotube (VACNT) foams. This improved the stiffness and energy absorption capabilities of the foams, and we are exploiting this to design better protective, ultra-lightweight materials.

What are your next steps?

We will study how materials behave in different conditions so that we can tackle the most common impact scenarios on helmet systems. We are also learning about the material’s thermal properties to make them robust for extreme environments, from Arctic cold to desert heat. Finally, we are working with our industry partner, Team Wendy, to test and learn about performance in more realistic conditions.

What are your proudest career achievements?

Numerous along the way like anyone else with a growth mindset – from topping the class during my undergraduate studies in Sri Lanka and getting a doctorate degree at Caltech, to joining UWMadison and now receiving an Early Career Award from NASA, Innovation Award from Wisconsin Alumni Research Foundation (WARF), and Outstanding New Mechanics Educator Award from the American Society for Engineering Education (ASEE). Closest to my heart is mentoring my students and seeing them reach for the stars in their own universe. It is pure joy to be part of their journey.

Theva’s top tips

1. In whatever pursuits you commit yourself to, don’t be afraid to fail and learn from those failures. Stay committed, focused and persevere—that is the way we will walk our way into the unknown.

2. Learn different things from sciences to arts. Hold on to the knowledge that one day they will come together to enable you to do mighty things!

Research to industry application

Meet Ron

Ron Szalkowski

Associate Director and Industry Lead, Team Wendy

Field of research: Material Development (helmet design for protection against TBI)

Funder: Office of Naval Research (subaward on an ONR grant to UW-Madison)

Research to industry application: www.teamwendy.com/about/science-andtechnology/innovate

How has your career path led you to the PANTHER programme?

I started at the company, Team Wendy, out of college. The company’s origins are in ski and snowboarding helmets, but it transitioned into making the inner padded liners for military helmets. I went from working in quality control to product development and, eventually, directing the engineering group. I was put in contact with Christian, who was trying to understand how brain cells become injured. We wanted to combine that type of cellular research with figuring out how to build better helmets, and even outfit them with sensors that could predict injury. Those ideas became part of the PANTHER programme.

Which three words best describe a ‘typical day’ for you on this research?

Collaborative. Challenging. Rewarding.

Why are helmets so important?

When your head is accelerated (sped up or slowed down) too quickly, the brain can become injured. A helmet allows those movements to occur more gradually, spreading out the forces over time, and even if it’s just for a fraction of a second, that can prevent a severe injury.

What types of tests do you conduct at Team Wendy?

We mostly conduct ‘drop tests’ in which the helmet is put on a metal head that is dropped onto a hard surface. Now, under PANTHER, we’re using a car crash test dummy to better replicate how a real person responds.

What key successes have you had so far?

A major moment was building a cap with sensors in it (the type inside every smartphone that can tell when you turn it), and using a new mathematical algorithm developed by partners at Brown University to crunch the data. It was able to perfectly match the measurements of a test dummy wearing it (the dummy was actually inside the compartment of an airplane that was dropped from 14 feet above the ground to simulate a crash landing). This showed us it would be possible to use wearable sensors and get very accurate data.

How close are you to introducing a new helmet to the market?

We could be releasing improved pad systems, performing better at high speeds, within the next year!

What are the next steps for your research?

We’re building a new test rig that will replicate a person’s full body falling onto the ground. We’re also developing computer simulations so we can run tests on different helmet designs without having to build them all in real life.

What are your proudest career achievements?

The first major ballistic (‘bullet resistant’) helmet I worked on was selected by the Australian Defence Force (ADF) to be issued to all soldiers. Winning that contract was a big achievement.

Ron’s top tips

1. Don’t be afraid to expand into different areas and learn new things, even if they seem outside your main area of focus. While the engineering field does require developing concentrated knowledge in certain areas, it can also allow you to learn ‘how to learn’ – and it’s helpful when you can combine technical knowledge with other strengths. Never stop learning!

2. I would encourage all types of prototyping, like building things in a makerspace, learning to fabricate with metals, building electronics, or woodworking, anything that interests you and allows you to learn skills along with gaining a deeper understanding of how and why things work. You can find tons of resources online for different areas of interest like this, as well as clubs to join to share and expand your knowledge with others.

Do you have a question for Christian and the PANTHER team?

Write it in the comments box below and Christian and the PANTHER team will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)