Taking metal to extremes

Dr Alexander (Sandy) Knowles and his team at the University of Birmingham, in the UK, are searching for metals that can withstand the extreme temperatures inside nuclear fusion reactors

NUCLEAR FUSION – joining of atoms to generate energy (E = mc2), typically tritium + deuterium (hydrogen isotopes with excess neutrons) → Helium + neutron + energy

NUCLEAR FISSION – splitting the atom, where a heavy unstable element such as uranium is split with a neutron into multiple smaller elements releasing neutrons + energy (E = mc2, which states that a change in mass during a nuclear reaction releases energy)

PLASMA – a physical state (similar to a gas) in which the atoms of a material are split up into separate electrons and nuclei

NANO-PARTICLE – the term for a particle between 1 and 100 nanometres in size. In comparison, human hair is ~70,000 nm thick

ALLOY – a metal made from a combination of multiples elements

SUPERALLOY – an alloy capable of withstanding extreme stresses, such as extreme temperatures

At the University of Birmingham, Dr Alexander (Sandy) Knowles and his team of metallurgists are experimenting with new materials and pushing them to their limits. They want to find a metal with which to build nuclear reactors, as they hope nuclear fission and fusion will provide us with cheap, clean energy that can help to prevent climate change.

WHAT IS THE DIFFERENCE BETWEEN FISSION AND FUSION?

Nuclear energy is a little like alchemy. The end product might not be gold, but it is all about transforming one element of the periodic table into another. The difference between fission and fusion is about which direction along the periodic table the transformation takes you.

Fission is the reaction that humans have cracked already and involves splitting the nucleus of a very heavy element to create smaller ones. Huge amounts of energy are released in the process, whilst no carbon dioxide is emitted. As Sandy explains, “One Coke can’s worth of nuclear fuel could produce your entire lifetime’s electricity use, carbon-free!” Fission is a low-carbon technology we can deploy widely now to address climate change.”

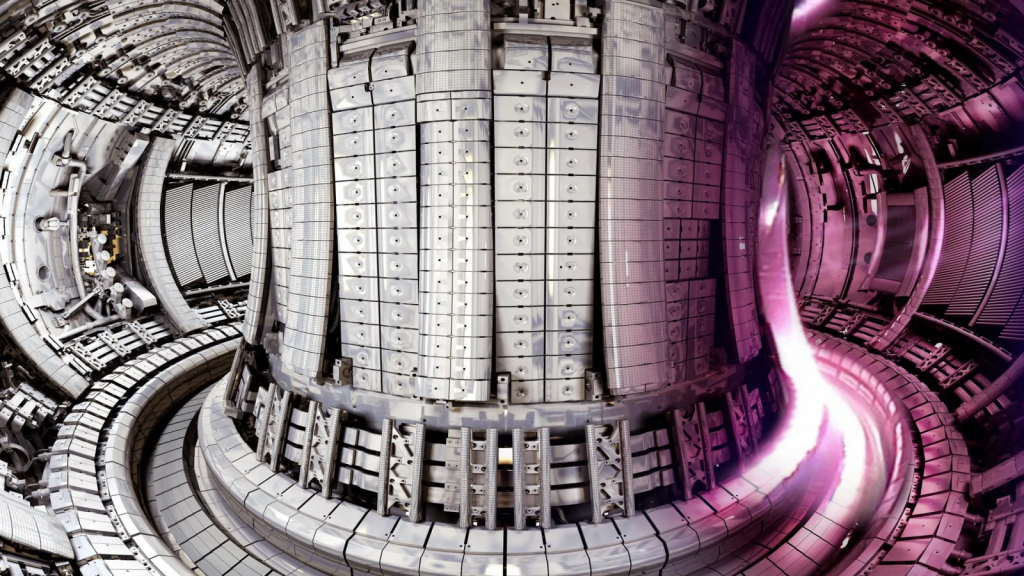

When it comes to fusion, scientists and engineers are still reaching for the stars. Fusion is the process that happens inside a star like the Sun, where small nuclei are squeezed together to make larger ones. It could be even more beneficial than fission because the input fuel (hydrogen) is almost limitless, and the reaction waste products are not radioactive. However, creating an artificial Sun on Earth is difficult. For fusion to work, the hydrogen needs to be heated to extreme temperatures to form a plasma, and this is where Sandy’s extreme metals come in.

HOW DO YOU CONTAIN PLASMA AT 150 MILLION DEGREES?

The temperature at the middle of a fusion reactor is ten times hotter than the centre of the Sun. It needs to be this hot because, on Earth, we do not have the massive gravity of the Sun which helps confine the plasma and promote fusion. Sandy explains, “The plasma is held in place by huge magnetic fields from superconducting magnets.” However, at some point there needs to be a physical barrier, and the temperature here could still be hotter than molten lava.

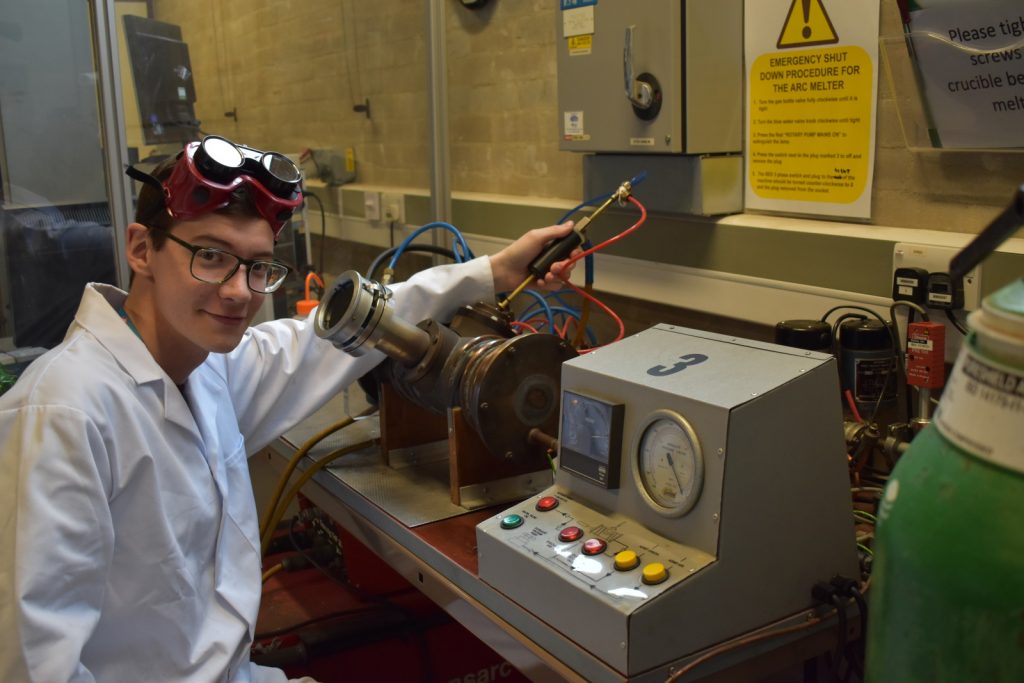

Tungsten is the metal with the highest melting point of all, but there is a problem. When the super-hot plasma spits out neutrons, this radiation can damage the metal. Sandy is looking for a way to reinforce tungsten using nano-particles and testing his new ‘superalloys’ in oven-like furnaces that go up to 2,000 °C.

HOW ARE SUPERALLOYS LIKE CAKE?

A cake is light, spongey and holds its shape – but is that anything like the physical properties of the flour, eggs or butter that it is made of? When elements are mixed in the right way, some remarkable chemistry can create a product that is completely different to any of the ingredients. The same is true for alloys, which are mixtures of metal elements.

Superalloys are alloys that are still strong even when they are close to their melting temperature. Sandy and his team have already created and tested some impressive tungsten-based superalloys. In one example, they fused tungsten with titanium and iron by heating the mixture to 1,250 °C for 100 hours. The resulting material – even when heated to 1,000 °C – was 20 times stronger than concrete!

HOW WILL SANDY’S METALS BE USED?

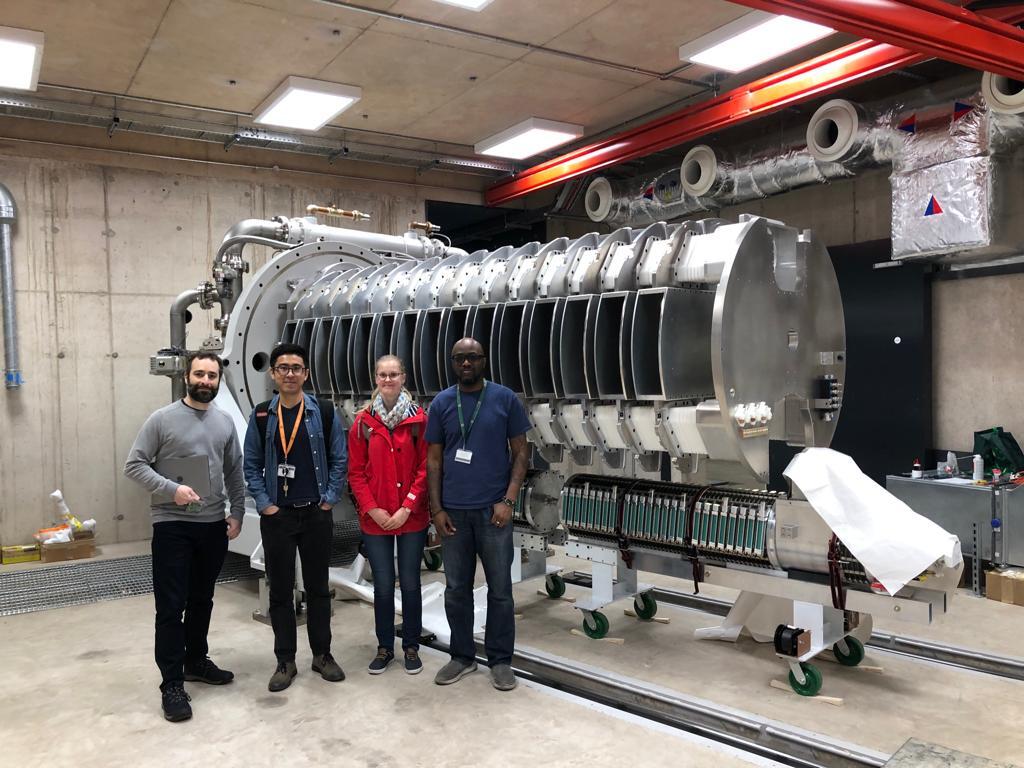

“Our goal is to construct commercial fusion power plants that can run for at least 20 years,” explains Sandy. “This means our materials must withstand the intense stress and energy from the fusion plasma for decades.”

There are still lots of experiments to do, therefore, to find the perfect material and prove it is robust enough for the job. Sandy’s team has access to particle accelerators, which can simulate the high levels of radiation his metals will experience in a fusion reactor.

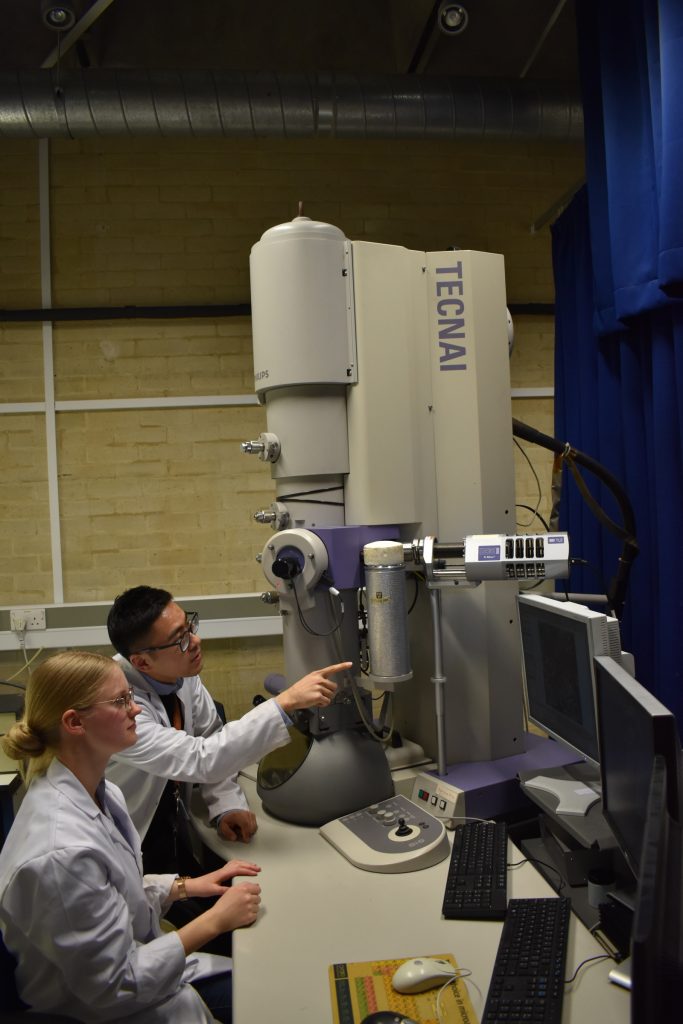

As well as testing the materials, it is also important for the metallurgists to understand why they behave as they do. By examining the metals with advanced microscopes, they are able to see how the atoms themselves are arranged and mixed.

Sandy explains, “We use scanning electron microscopy (SEM) as well as transmission electron microscopy (TEM). SEM looks at the surface, whilst TEM looks through the material and allows greater resolution – down to atoms!”

This insight allows the team to be innovative. Sandy says, “In my group, we try to go back to first principles to see if there are untrodden paths.” By keeping their minds open, Sandy and his team might just discover a metal that could change everything.

DR ALEXANDER (SANDY) KNOWLES

DR ALEXANDER (SANDY) KNOWLESAssociate Professor in Nuclear Materials, UKRI Future Leaders Fellow & Royal Academy of Engineering Associate Research Fellow, University of Birmingham, UK

FIELDS OF RESEARCH: Materials Science, Experimental Metallurgy, Microscopy

RESEARCH PROJECT: Creating and experimenting with new materials for use in extreme environments, such as nuclear reactors

FUNDERS: This work was supported by: UKRI Future Leaders Fellowship (MR/T019174/1), Royal Academy of Engineering Research Fellowship (RF\\\\201819\\\\18\\\\158), EUROfusion Researcher Grant Fellowship (AWP17-ERG-CCFE/Knowles), EPSRC Grants (EP/T01220X/1 and EP/T016566/1), EU H2020 COMPASsCO2, UKAEA/ CCFE, NNL, TIMET, Rolls Royce

With its roots in blacksmithing and steel production, metallurgy is the study of all things metal. This includes not only the 94 metallic elements in the periodic table but also the compounds they form and the alloys that can be produced by mixing them together. Metallurgists create, examine and test these materials so they can be used for construction and technology. Their work is all around us in bridges, engines and electronics; over our heads in spacecraft; and behind the scenes in many production lines and power plants.

WHAT HAPPENS IN AN EXPERIMENTAL METALLURGY LAB?

Much of the work in metallurgy happens in the lab, where there are four main stages:

1. A design for a new alloy is suggested, along with a recipe for how to make it.

2. The material can then be produced by a combination of melting, mixing and baking.

3. The results are examined using electron microscopes to find out exactly what has been produced.

4. The material is tested for whatever properties are important, such as strength, weight, durability or heat resistance.

Sandy describes his job as “curiosity-driven research”. It is exciting to think of something nobody has tried before, persuade other people it is worth researching and then find out if it really works. Science always comes with the risk that not everything will work, but “exploration into the unknown, with the possibility to open up new technologies” is what drives Sandy and his team.

DO EXPERIMENTAL METALLURGISTS WORK IN RESEARCH OR INDUSTRY?

Both! Creating a new material is a process of research and development, and while universities do lots of research, it tends to be companies that develop the results into a final product. It is important, therefore, for experimental metallurgists – wherever they work – to understand both parts of the process.

Reference

https://doi.org/10.33424/FUTURUM281

WHAT OPPORTUNITIES ARE THERE FOR FUTURE METALLURGISTS?

As technology progresses, every generation of metallurgists gets a better understanding of how materials work, so the future undoubtedly holds new discoveries. There are plenty of challenges that metallurgists will need to solve in the coming decades. For example: can we find a way to sustainably source metals for electric vehicle batteries? How can we recycle the metals in the ever-growing amount of electronic waste? Could better metals help us transition to renewable energy as well as nuclear power?

HOW DID SANDY BECOME AN EXPERIMENTAL METALLURGIST?

“From an early age, I was LEGO obsessed, and then I was into models and computers. If I were a kid now, I am sure I would be playing with Raspberry Pi & Arduino – these are great ways to get into coding and engineering. Outdoor sports have been another long-term interest, from mountaineering to skiing, cycling and running.

As a youngster, I was inspired by a family friend who was a flight engineer, maintaining aeroplanes in-flight next to the pilots. I was gutted when I heard the role no longer existed! I then turned my head to architecture, then engineering, then chemistry, until eventually, I came across materials science. The blend of engineering, physics and chemistry it uses to reveal the ‘science of materials’ is the perfect fit for me!

I chose to specialise in metallurgy because I liked the connection to large-scale engineering and the hands-on experiments. My interest in aerospace, fusion and nuclear grew after working on jet engines with Rolls Royce on a summer internship. I now also do work on thermal solar power and hydrogen energy storage – metallurgy has opened up a wide variety of work for me, much of which helps to address the climate emergency.

Curiosity and determination enable me to think creatively, research if an idea is viable, design experiments, get hands-on in the lab, analyse the data and then put the results out into the world. Teamwork is also important, be it helping each other in the lab or meeting with collaborators from other universities and industry partners around the world.

When you enjoy your job, the work-life boundary can become blurred! I want to see my ideas come to fruition, the team is enthusiastic, and we feel part of the societal move to net-zero. That said, I make plenty of opportunities to spend time with friends and family, enjoying sports and travel.”

SANDY’S TOP TIPS

1. Pick a direction to go in and work hard for it, but don’t feel you have to be tied to it forever. My career decisions are often guided by keeping my options open. I started in aerospace, moved to nuclear fusion and now also do hydrogen and solar energy!

2. Some of the most useful internships/work experiences I did were the ones that told me I didn’t like a particular area.

3. Talking to people at different career stages about their career routes was a great way to work out what I wanted to do myself.

• Metallurgists often study for a degree in materials science, but you can also readily enter the field from a background in physics, chemistry or engineering.

• A good level of maths is required across many science and engineering degrees. Chemistry, physics, biology, computer science and design technology are all useful too.

• To work in research and development, it is useful to obtain a master’s degree and, possibly, also a PhD.

MEET THE TEAM

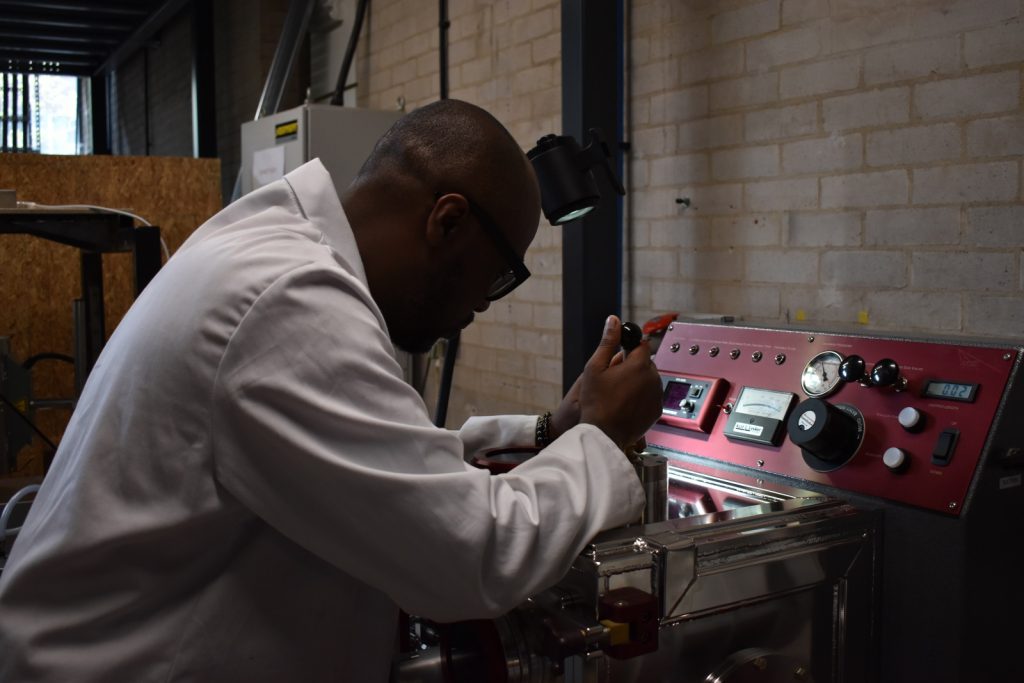

MANGALISO BROWN

Laboratory and Research Technician

Designing, developing, assembling and maintaining laboratory equipment. Implementing and monitoring the compliance of health and safety.

“There are always opportunities to learn and try new things in metallurgy and materials. My day can include anything from analysing samples to troubleshooting why an experiment isn’t going to plan and anything in-between. I’m always learning and looking for new challenges.”

Go through life enjoying every moment; learn from the lows and embrace the highs.

VINCENT GAGNEUR

PhD Researcher

Studying the micromechanics of novel titanium alloys for aerospace gas turbines.

“I like the diversity of the experimental techniques that can be used, as well as the freedom to shift from one to another. This allows me to be creative in the lab. Diving into theoretical literature can be challenging, but it’s an important part of the work. I started coding automated data analysis software codes out of laziness! It resulted in helping a few co-workers and opening a route for more research.”

Surround yourself with people you trust – they’ll push you towards things you care about.

JÓHAN MAGNUSSEN

PhD Researcher

Exploring alloys for next-generation nuclear power plants, with the potential to improve the efficiency of electric power generation for the future.

“The science of metallurgy has direct connections to real-world problems. In the case of zirconium alloys that I work on, an improvement in alloy design could improve nuclear power plant efficiency and/or lifetime, both of great worth to society. The field of alloy design draws on most aspects of metallurgy, so it takes a greater breadth of knowledge than some other fields. The challenge lies in collating results and maintaining a balance of properties.”

TOP TIP

Enjoy your work – you don’t need to be in a hurry to reach a specific goal.

SOPHIA VON TIEDEMANN

PhD Researcher

Developing new iron-based superalloys for very high temperatures and nuclear applications. Researching the microstructure of different alloy systems and how proton irradiation affects their properties.

“I find it fascinating to see how performing certain treatments on a material changes the microstructure and, hence, its properties. For example, shooting protons at a material changes its structure through the displacement of atoms, which we can see through electron microscopy and measure physically through analysing hardness. It’s motivating to know that this research plays a vital role in establishing low-carbon energy solutions for the future.”

TOP TIP

Learn to take things as they come.

DR TIANHONG GU

Research Fellow

Analysing superalloys and developing an understanding of microstructure and advanced characterisation techniques, applied to aerospace and nuclear energy. Teaching and supervising MSc and PhD students.

“Designing the undergraduate and postgraduate projects for students, as well as designing and setting up new experiments can be challenging, but it is also very rewarding, and I enjoy the friendly scientific environment and the variety my role offers. I have been motivated to become an independent scientist in the field and want to encourage more female students to join the metallurgy and materials community. Publishing my research in leading international peer-reviewed journals and supervising successful students are proud moments for me.”

TOP TIP

Trust yourself!

DR PEDRO A. FERREIRÓS

Research Fellow

Designing and developing new alloys for turbines and nuclear power reactor applications.

“The beauty of being a scientist is that the more one discovers, the more questions are generated, and this never-ending desire for knowledge gives us surprising results. Our work involves teamwork that is constantly enriched by young students and guiding them is the key to generating knowledge together. Our experiments using cutting-edge technology allow us to study from nanometric scales, how atoms are periodically arranged and what defects are generated in these arrangements, to finally define the mechanical properties of the alloys.”

Scan the QR code to visit the team’s website:

EXPLORE CAREERS IN EXPERIMENTAL METALLURGY

• Sandy recommends Discover Materials as a “fantastic new and growing initiative that delves into what materials science is all about and the latest exciting research”.

• UK-based Prospects provides useful information on the types of careers and responsibilities in metallurgy.

• Read more about metallurgy training, jobs and salaries in the US at:

www.environmentalscience.org/career/metallurgist

Do you have a question for the team?

Write it in the comments box below and Sandy, Mangaliso, Vincent, Jóhan, Sophia, Tianhong or Pedro will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)