The big shake: designing tall timber buildings that are resilient to earthquakes

Six universities are involved in a collaborative research project to introduce a special type of resilient timber building across the USA. The NHERI TallWood project aims to prove that tall timber buildings can be resilient to earthquakes, while having a whole host of other advantages

TALK LIKE A STRUCTURAL ENGINEER

Cross-laminated timber (CLT) – a type of wood panel created by gluing together layers of wood perpendicular to one another (similar to how plywood is manufactured).

Lateral loading – a horizontal force acting on a structure, such as wind, an earthquake or waves.

Mass timber – a category of framing techniques characterised by the use of solid wood panels and large-dimension wood columns and beams. CLT is a type of mass timber component.

Resilience – the ability of a structure to recover its functionality after experiencing the effects of an external disruptive force.

Rocking wall system – a type of structural design that allows walls in the building to move (‘rock’) when exposed to an external force and return to their original shape once the force has passed.

Seismic – an adjective used to describe effects related to earthquakes.

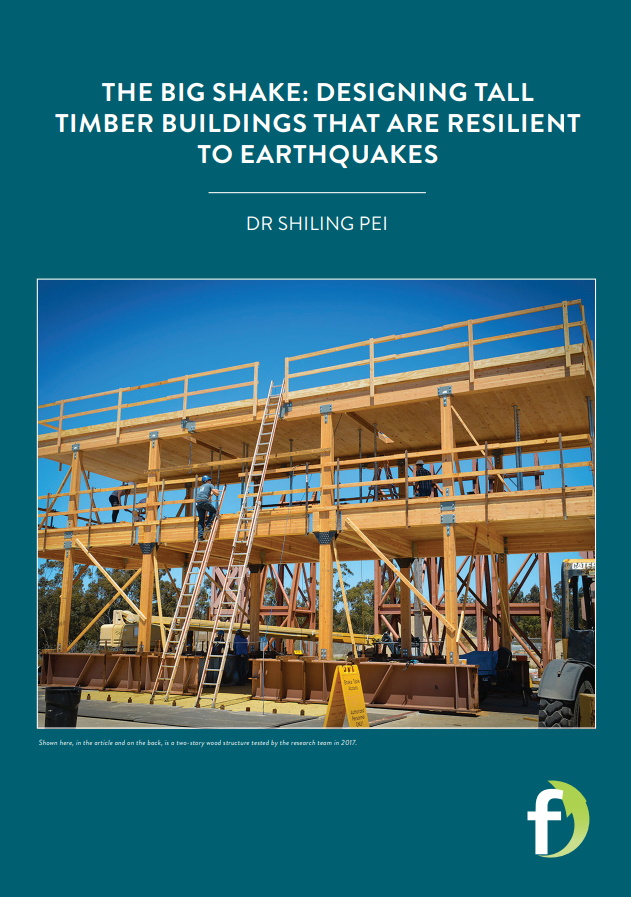

Shake table – a large platform that can reproduce earthquake ground shaking, used to test the seismic performance of buildings and other structures. The world’s largest outdoor shake table used in this project is part of the NSF NHERI (Natural Hazards Engineering Research Infrastructure) programme, which provides this equipment to researchers when they need to test something really big.

Large-scale timber construction is on the up. New building techniques mean that many of the limitations of using wood are no longer insurmountable, and there is increased interest in timber as a sustainable building material. The production of steel and concrete accounts for 8% of all global CO2 emissions – a staggering amount – so finding alternatives for construction is essential. If harvested correctly, trees are a renewable resource and when they are incorporated into buildings, they also have an important role in keeping carbon out of the atmosphere.

Wood brings with it its own challenges. The danger of fire, for instance, requires careful attention, although the risks are much less than might be assumed and teams all over the world are helping to minimise these risks even further. Additionally, rigorous tests are used to investigate wood’s structural capabilities, which are constantly improving as new engineering techniques are developed. Then, the buildings’ responses to natural disasters, in particular earthquakes, must be considered. This is what the NHERI TallWood team focuses on.

The team consists of a mix of academics and practitioners, all keen on advocating novel construction methods. In particular, they want to demonstrate that their building techniques are resilient to earthquakes. Computer simulations and small-scale models are one thing, but the project aims to take it to the next level: to simulate an actual earthquake on a full-scale building. This involves a gigantic piece of equipment called a ‘shake table’, which does exactly what you might imagine.

Dr Shiling Pei (known as Ling) is the principal investigator of the project. He believes that large wood-based buildings have a strong future in the USA. “Almost 90% of residential buildings in the USA are constructed from wood because of its affordability and accessibility,” he says. “Other countries use wood in their housing to different degrees – around 55% in Japan and next to nothing in China.” It is difficult to build larger buildings out of traditional planks of wood, but through some canny construction methods that have been developed over the last couple of decades, wood buildings over 10 stories high can become commonplace.

MASS TIMBER

Mass timber is an engineered timber product that consists of multiple layers of timber, joined (laminated) together to form a solid structural component. The NHERI project focuses on the use of cross-laminated timber (CLT). CLT is made from lumber harvested from small diameter trees that are glued in perpendicular layers (crossways) under high pressure. These solid panels can then be cut to the desired shape. “Mass timber expanded the wood building market by allowing the construction of large-scale commercial buildings using wood,” says Ling. “It’s a highly efficient pre-fabrication process that requires little manpower or time on the building site, which suits the shortage of manual labour common to many developed countries.” It also has an aesthetic advantage too. “People love exposed wood, so much so that they will commonly cover concrete or steel building interiors with wood panels. So, why not just use real wood when we can?”

Reference

https://doi.org/10.33424/FUTURUM86

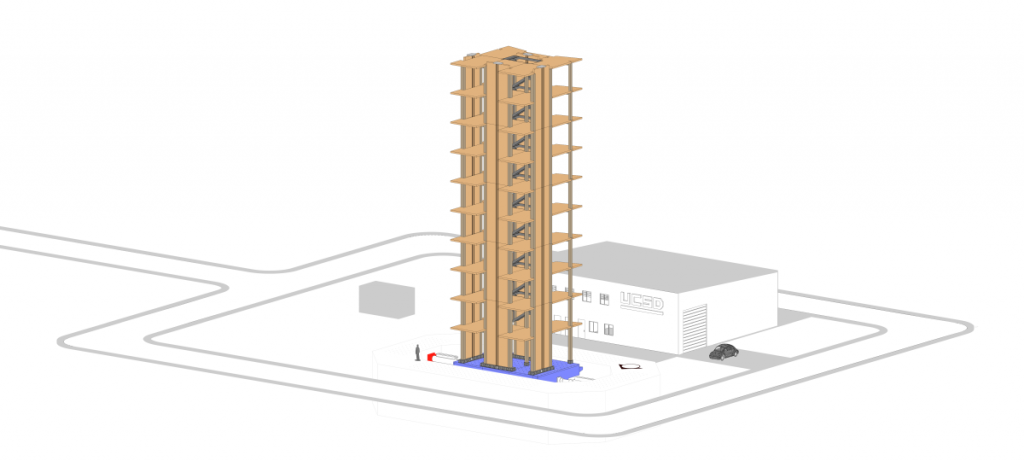

Full-scale 10-story wood building to be tested at NHERI@UCSanDiego.

See: http://nheri.ucsd.edu

Large-scale timber construction is on the up. New building techniques mean that many of the limitations of using wood are no longer insurmountable, and there is increased interest in timber as a sustainable building material. The production of steel and concrete accounts for 8% of all global CO2 emissions – a staggering amount – so finding alternatives for construction is essential. If harvested correctly, trees are a renewable resource and when they are incorporated into buildings, they also have an important role in keeping carbon out of the atmosphere.

Wood brings with it its own challenges. The danger of fire, for instance, requires careful attention, although the risks are much less than might be assumed and teams all over the world are helping to minimise these risks even further. Additionally, rigorous tests are used to investigate wood’s structural capabilities, which are constantly improving as new engineering techniques are developed. Then, the buildings’ responses to natural disasters, in particular earthquakes, must be considered. This is what the NHERI TallWood team focuses on.

The team consists of a mix of academics and practitioners, all keen on advocating novel construction methods. In particular, they want to demonstrate that their building techniques are resilient to earthquakes. Computer simulations and small-scale models are one thing, but the project aims to take it to the next level: to simulate an actual earthquake on a full-scale building. This involves a gigantic piece of equipment called a ‘shake table’, which does exactly what you might imagine.

Dr Shiling Pei (known as Ling) is the principal investigator of the project. He believes that large wood-based buildings have a strong future in the USA. “Almost 90% of residential buildings in the USA are constructed from wood because of its affordability and accessibility,” he says. “Other countries use wood in their housing to different degrees – around 55% in Japan and next to nothing in China.” It is difficult to build larger buildings out of traditional planks of wood, but through some canny construction methods that have been developed over the last couple of decades, wood buildings over 10 stories high can become commonplace.

MASS TIMBER

Mass timber is an engineered timber product that consists of multiple layers of timber, joined (laminated) together to form a solid structural component. The NHERI project focuses on the use of cross-laminated timber (CLT). CLT is made from lumber harvested from small diameter trees that are glued in perpendicular layers (crossways) under high pressure. These solid panels can then be cut to the desired shape. “Mass timber expanded the wood building market by allowing the construction of large-scale commercial buildings using wood,” says Ling. “It’s a highly efficient pre-fabrication process that requires little manpower or time on the building site, which suits the shortage of manual labour common to many developed countries.” It also has an aesthetic advantage too. “People love exposed wood, so much so that they will commonly cover concrete or steel building interiors with wood panels. So, why not just use real wood when we can?”

The cross-laminate process means that a lot of the construction work can be done off-site, and the prefabricated product then transported to the building site. This has plenty of advantages: it saves the cost of transporting a lot of construction machinery and workers to the site, and also means that the building process itself is relatively quick, which is good news for neighbours and local infrastructure. It has advantages over ‘traditional’ wood in that it can be built to any size and can be specifically engineered to be strong and resilient.

PROTECTING AGAINST THE FORCES OF NATURE

Natural disasters are often catastrophic for developed regions. Earthquakes and hurricanes, for instance, have been known to level entire districts. It is only in the last a few decades that urban buildings have been designed with earthquakes in mind – in the world of engineering, this is expressed through accounting for the phenomenon of lateral loading.

“Lateral loading is when a strong force comes from a horizontal direction, such as a strong wind or an earthquake,” says Ling. This is opposed to the vertical force of gravity, which is constant. “Lateral forces are transient, dynamic and violent. Lateral resistance is how buildings counter them, and incorporating a lateral force-resisting system is a key focus for building design.”

Lateral force-resisting systems need to have the strength to overcome lateral loading, and not deform so much that the building’s structure is damaged. “A lot of existing lateral systems such as concrete walls or steel frames are very strong, but if they do get deformed, they are very difficult and expensive to repair.” The team members think they have a solution: a resilient wood rocking wall system, where the building is allowed to deform to some degree and then spring back into shape. This is something that nature has been doing for millennia; you can see it in the bending of tree branches on a windy day.

THE WALL THAT ROCKED

Ling’s team has designed a rocking wall system that should be able to resist earthquakes and other natural events. “It basically consists of a solid wood wall panel anchored to the ground using steel cables under tension. When exposed to lateral forces, the cables will allow the walls to rock up – which increases the building resilience – and can then pull the building back to plumb once the forces are gone.”

In terms of physics, it is as if the building is held to the ground with big rubber bands. When a force pushes from the side, the rubber bands can stretch and allow it to move in that direction, before snapping back into their original shape once the force has passed. The concept is elegantly simple, but the design and floor plan needs careful thought, which is what this NHERI TallWood project is all about.

THE SHAKE TEST

The NHERI TallWood team has access to the world’s largest outdoor shake table, which is where they carry out their earthquake tests. “The shake table is basically a huge steel block foundation driven by hydraulic pistons that are controlled using computers,” says Ling. It can even replicate past earthquakes using seismic recordings. For instance, the team already carried out a test on a two-storey mass timber building by simulating shaking from the Northridge Earthquake, a magnitude 6.7 earthquake that struck Los Angeles in 1994.

The next shake test on the table involves a much bigger construction: a ten-storey building. “This test will validate the resilience of our design methodology, and will also be an important opportunity to educate the public,” says Ling. “It will demonstrate the potential benefits of constructing tall buildings out of wood and, with any luck, will also inspire the next generation of engineers and scientists.”

THE POWER OF COLLABORATION

“The people are definitely the highlight of this project,” says Ling. “Our team is a coalition of researchers, engineers, architects, contractors, representatives of the wood industry and project stakeholders.” Upon completion of many scientific research projects, there is a time-consuming process to make their results applicable to the real world. By directly involving designers and manufacturers, the NHERI TallWood project skips this step and makes the process as seamless as possible.

Shiling Pei P.E.

Shiling Pei P.E.

Associate Professor

Department of Civil and Environmental Engineering Colorado School of Mines

Role: Project lead, overseeing the collaborative efforts between the six universities involved, and preparing for the 10-storey shake table test.

Project: The NHERI TallWood Project aims to develop a resilience-based seismic design methodology for tall wood buildings of the future. This research project is supported by the National Science Foundation through a number of collaborative awards including: Civil, Mechanical and Manufacturing Innovation (CMMI) 1636164, 1634204, 1635363, 1635227, 1635156, 1634628.

Shiling Pei P.E.

Shiling Pei P.E.

Associate Professor

Department of Civil and Environmental Engineering Colorado School of Mines

Role: Project lead, overseeing the collaborative efforts between the six universities involved, and preparing for the 10-storey shake table test.

Project: The NHERI TallWood Project aims to develop a resilience-based seismic design methodology for tall wood buildings of the future. This research project is supported by the National Science Foundation through a number of collaborative awards including: Civil, Mechanical and Manufacturing Innovation (CMMI) 1636164, 1634204, 1635363, 1635227, 1635156, 1634628.

DR JOHN VAN DE LINDT

Harold H. Short Endowed Chair

Professor

Department of Civil and Environmental Engineering

Colorado State University

Role: Leading the development of the project’s design methodology and helping to plan the 10-storey shake test for 2021.

RESILIENCE AND PERFORMANCE

Resilience is a vitally important part of structural engineering. It describes the ability of a structure to be able to ‘bounce back’ after it is impacted by a natural hazard such as an earthquake. Importantly, it is different from performance, which simply describes how well a structure can resist a force and keep damage to a minimum while protecting people inside. Resilience is often a better solution since performance only focuses on the building. Design codes based on performance minimally strive to preserve life safety, meaning people survive but the building may be unrepairable post-earthquake. The concept of resilience allows a building that becomes damaged to be more easily repaired and functional again, and support the recovery of the whole community around it.

BUILDING IN RESILIENCE

“There are two main ways that we can build resilience into structure,” says John. “The first involves basic design, limiting the movement of the building to avoid damage to its components, or directing damage to sacrificial ‘fuse’ components that are easily replaceable. The second involves a complex computer model that simulates repair following damage.” It is often impossible to avoid all damage in the event of an earthquake, but minimising it and even channelling it to less essential or easily repairable components can help make the repair process as easy as possible.

“We aim to go a step further than resilience of individual buildings,” says John. “We want to build in community resilience, which means that society as a whole can remain functional after the earthquake, to support social institutions, the economy and overall societal wellbeing. Resilient buildings are an important component of community resilience – they are built with the community in mind. Especially following a natural disaster, buildings like these could become focal points to help an area’s recovery.

DR JEFFREY BERMAN AND DR DANIEL DOLAN

Professors

Department of Civil and Environmental Engineering

Washington State University

Role: Building computer models to simulate the effects of an earthquake on the buildings the team is designing.

VIRTUAL EARTHQUAKES

Before getting underway with the shake table, it is important to have a good idea of what is going to happen. Building a ten-storey building and then giving it a good shake is no easy task, after all, so it is advantageous to be able to anticipate as many potential issues as possible, especially if there are ways the building design could be improved beforehand.

“We and our graduate students are responsible for predicting the seismic response of the ten-storey test using computer models,” says Jeff. “These will help us understand how the design might be changed to improve the building’s resilience.” The team has particular goals in mind – for instance, limiting the damage from earthquakes of a particular intensity. Ideally, they want buildings to suffer no damage from smaller (and more frequent) earthquakes, and only repairable damage from larger (infrequent) earthquakes.

“Our simulations are founded in the science of mechanics,” says Jeff. “Using advanced programming and applied math, the computer models replicate the physics of a building in an earthquake. This is actually quite complicated and involves a lot of learning to get it right.”

A SECOND ROCKING JOINT

The team is investigating whether a second rocking joint could be beneficial. So far, the building rocks at ground level, before being pulled back into position. It is possible that putting a second joint halfway up (at the fifth storey) could further increase resilience. However, this brings its own challenges – for instance, ensuring the building and all its individual components have the capacity to be able to bend at this joint and fall back into place afterwards. “So far, we have found that these CLT wall systems have excellent seismic performance,” says Jeff. “They limit the damage to the structural components of buildings even in large and infrequent earthquakes.

DR KERI RYAN

Professor

Department of Civil and Environmental Engineering

University of Nevada, Reno

Role: Incorporating resilience into non-structural components of the building.

BEYOND THE ROCKING WALLS

Keri’s role focuses on the building’s non-structural components and their resilience to earthquakes. These are integral parts of a building that do not directly contribute to holding it up: for instance, interior walls, stairs and elevators, as well as plumbing, and electric and ventilation systems. “Research on resilient non-structural components is still in its infancy compared to structural systems,” says Keri. “A shake table test that we conducted back in 2011 was what first alerted me to the amount of damage they sustain.”

“Most seismic engineering research to date has focused solely on the lateral resistance of structural components,” she continues. “However, non-structural components are often highly damaged during earthquakes. After the 1994 Northridge Earthquake, about half of the damage cost to buildings was due to non-structural components. This highlighted the need to address vulnerabilities in non-structural systems.”

Even if a building remains structurally sound after an earthquake, non-structural damage can ultimately harm its structural integrity. For instance, damage to exterior cladding (the building envelope) can mean that the underlying structure is exposed to weather. Many non-structural components are also crucial to a building’s safety. Damage to stairs, for instance, can trap occupants within a building after a natural disaster, as happened in the 2011 Christchurch Earthquake in New Zealand.

ALONG THE WALLS AND UP THE STAIRS

The rocking wall system only works if everything moves with it. If the building’s structure is designed to flex during an earthquake, the parts within its interior need to move with it or risk getting crushed or broken. This is known as deformation compatibility. “We are focusing on interior walls, the building envelope, and stairs as the most integral non-structural components,” says Keri. “We are working closely with designers and other specialists to identify how to make improvements wherever we can.”

For interior walls, they are investigating an innovative solution known as a ‘slip track’. “This is when the top of the wall is not directly connected to the above floor slab, and thus can move independently or slip relative to the floor above.” This works well until these walls meet at corners, at which point there is the risk of collision and damage. Now the team is working on the finer details of how to minimise damage at the corners.

Stairs are also a big area of interest. “Stairs are typically rigidly connected between floors and are often damaged during earthquakes, and are then deemed unsafe for future use,” says Keri. “US building regulations have changed to address this, but there’s still a lot of research that needs to be done to get the best design.” Similar to interior walls, the prime solution is to detach the stairs from the floor at one end, so if the floors move independently the stairs are not stretched or compressed between the two. The team has partnered with a construction innovation company and will compare several solutions to solve this challenge. methodology and helping to plan the 10-storey shake.

DR JAMES RICLES AND DR RICHARD SAUSE

Bruce G. Johnston Professor of Structural Engineering and Joseph T. Stuart Professor of Structural Engineering

Civil and Environmental Engineering

Lehigh University

Role: Investigating the effects of lateral force using subassemblies.

FROM THE SIDE AND THE FRONT

The Lehigh team investigates the lateral resistance of timber buildings with CLT walls. In particular, they examine bidirectional loading, which is when lateral force comes from several directions at once, as is common with earthquakes. For walls, this means examining what happens when forces parallel to the wall (for which it is designed) combine with forces perpendicular to the wall. The team is investigating this by building a constituent part of the building’s walls and adjacent floors (a subassembly) and then using hydraulic actuators to subject the building to bidirectional forces.

“We developed specific software for these tests,” says James. “The software uses real-time data, which gives it a highly realistic output.” It also considers the interaction of walls with other components of the buildings, such as stairs and floors. This is important as any part of the building can influence its overall resilience, so making sure to account for everything is crucial. It is the first time that these walls have been tested in this way in the USA.

RESULTS FOR THE REAL WORLD

“Testing a large-scale building requires careful consideration of what we aim to find out,” says James. “This is in addition to managing costs and schedule, as well as maintaining a safe environment for the research team.” They must always make sure that their results reflect something of real-world value, something that usefully expands the knowledge available on this topic.

“We have found that the walls get damaged more easily when exposed to bidirectional loading rather than unidirectional loading,” says James. “This has important implications for the building’s seismic resilience, which will help us finalise the design details for the 10-storey building.”

CIVIL ENGINEERING AND STRUCTURAL ENGINEERING: WHAT’S THE DIFFERENCE?

Civil and structural engineering are two branches of engineering. In some ways they are closely related, but careers-wise they can follow quite different paths. In brief:

• Civil engineering is broader in scope and includes structural engineering as a specialty. General civil engineering tends to concern large-scale public systems, such as land development, transportation systems, water and energy distribution systems, and dams.

• Structural engineering concerns structures such as bridges and skyscrapers. It is focused on designing structures using steel, concrete, wood and masonry materials.

In terms of education, it is unusual to see a direct focus on structural engineering at the beginning of undergraduate study. Within civil engineering, students will often have the option to specialise in structural engineering at the end of the programme.

• According to Top Universities, the best universities for civil engineering in the world are MIT, Delft University of Technology (Netherlands), Cambridge, University of California – Berkeley, and Imperial College London.

• According to the Institute of Civil Engineers, useful subjects to take to prepare for a civil engineering degree are maths, physics, geography and geology, computer science and languages.

• Civil engineering careers do not always require a degree. Apprenticeships are relatively common for this discipline both in the US and the UK. In the UK, the top employers for engineering apprenticeships are BAE Systems, National Grid and BAM Nuttall.

• Civil engineering is often a well-paid career. The average civil engineer in the US makes around $87,000 a year, according to US News.

Got a question for Ling and the team?

Write it in the comments box below and the researchers will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)