The fastest electric motor ever is another step towards a sustainable future

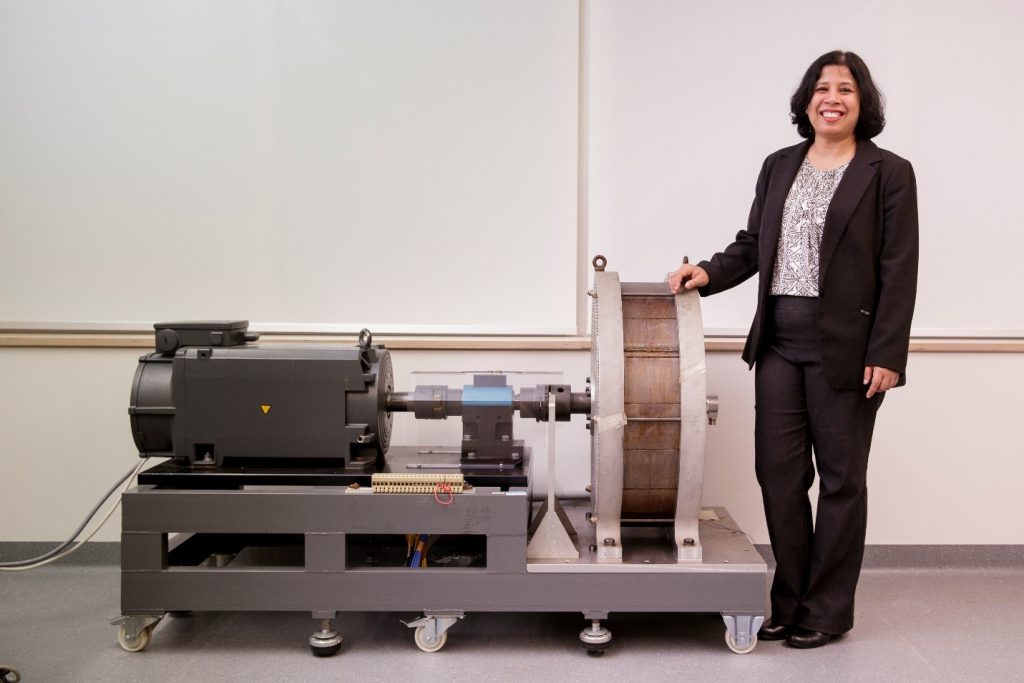

Professor Rukmi Dutta and her team at the University of New South Wales, Australia, have developed a new electric motor that runs at high speeds and uses less power, which ultimately means less pollution.

TALK LIKE AN … ELECTRICAL ENGINEER

Alternating current (AC) — a form of current where electrical charges periodically reverse the direction of their motion

Centrifugal force — an apparent outward force on an object that is moving in a circle. For example, a moving merry-go-round can make you feel like you are being propelled outwards.

Direct current (DC) — a form of current where electrical charges move in only one direction

Electric motor — a machine that uses magnetism to convert an electric current into motion

Magnet — an object that produces a magnetic field. There are different types of magnets (see www.toppr.com/guides/physics/electronics/types-of-magnets). Rukmi works with permanent magnets, which are formed of naturally occurring minerals with magnetic properties. Conventional electric motors and generators mostly use electromagnets, which are formed via magnetic induction

Rotor — a moving magnet, a key element of an electric motor rpm — revolutions per minute, the unit of rotational speed

Stator — an unmoving magnet, one a key element of an electric motor

Torque — a measure of the force that can cause an object to rotate around an axis

Work — in physics, a force causing the movement – or displacement – of an object

To fight climate change, we must phase out the use of fossil fuels such as coal, oil and gas. This is easier said than done: decarbonising our societies and maintaining high standards of living for people around the world requires not only changes in behaviour, but also technological innovation. Associate Professor Rukmi Dutta of the School of Electrical Engineering at the University of New South Wales (UNSW Sydney) is improving the efficiency of electric motors and, therefore, reducing their environmental impact. Given that these motors can be used in electric cars and even aircraft, this will make an important contribution to the fight against climate change.

What is an electric motor?

An electric motor uses the principles of magnetic fields to transform electric currents into work. The idea is simple. An electric motor has a stator, a stationary magnet that creates a magnetic field. Inside the stator – and therefore inside the magnetic field – is another part, usually a cylinder called the rotor. Because moving charges generate a magnetic field, the rotor also becomes a magnet when an electrical current runs through it. The ‘north’ pole of the rotor is attracted to the ‘south’ pole of the stator, causing the rotor to rotate. The direction of the current is switched at the exact moment when the rotor and stator align, transforming the north pole of the rotor’s magnet into a south pole. The new north and south poles are then attracted to opposite poles of the stator, and the rotor continues to turn. The constant switching of the current’s direction keeps the rotor spinning. When the rotor is attached to, for example, the wheels of a car, this motion is turned into useful work.

There are many types of electric motors: some use alternating current (AC), while others use direct current (DC); some rely on the induction of magnetic fields, as described above, while others contain permanent magnets; and some have magnets on the surface of the rotor, while in others the magnet is embedded within the material of the rotor itself. Rukmi works on a specific type of electric motor called an interior permanent magnetic synchronous machine (IPMSM). These motors typically use AC and have permanent magnets embedded in the rotor.

How did Rukmi innovate and improve on existing IPMSMs?

Reference

https://doi.org/10.33424/FUTURUM357

IPMSMs have several features that make them better than other electric motors. Embedding the magnets inside the rotor generates more torque: the cylinder spins not only because of interaction between the magnet and the AC but also because of additional rotation caused by the resistance of the rotor material to the magnetic field, a property called ‘magnetic reluctance’. These machines can also run at a high speed without needing a lot of power, which means smaller IPMSMs can do the same amount of work as other types of larger motors. Compact, light motors are ideal for use in cars and planes, where space and weight capacity are limited.

However, IPMSMs also have a weakness. The internal magnets are held in place by thin iron bridges. As Rukmi explains, “If the rotors are spun at a very high speed, such as 50,000 rpm or more, these bridges are subjected to high mechanical stress caused by the centrifugal force. If we widen the iron bridges to make them withstand the stress, it will compromise the electromagnetic performance of the IPMSM.”

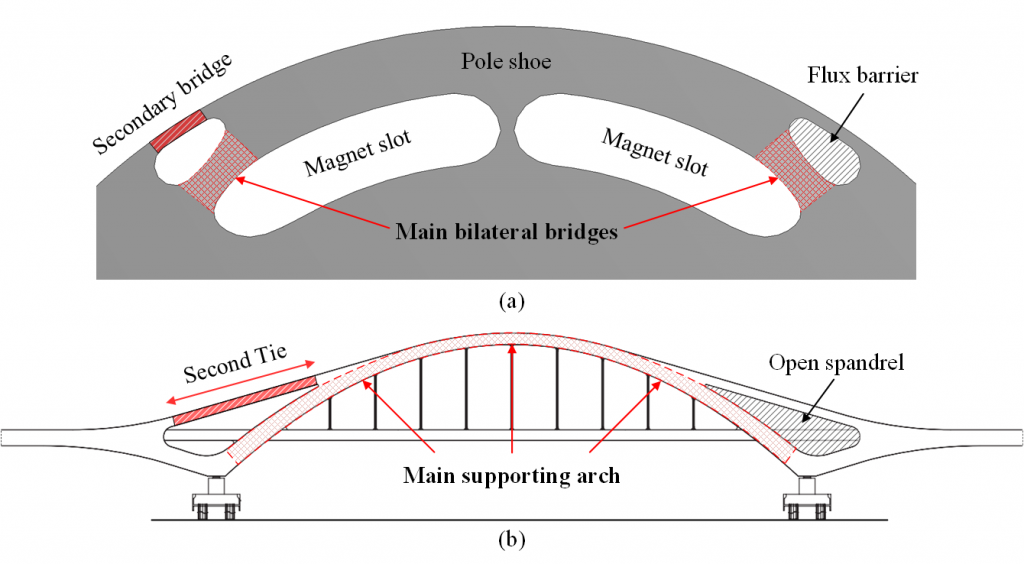

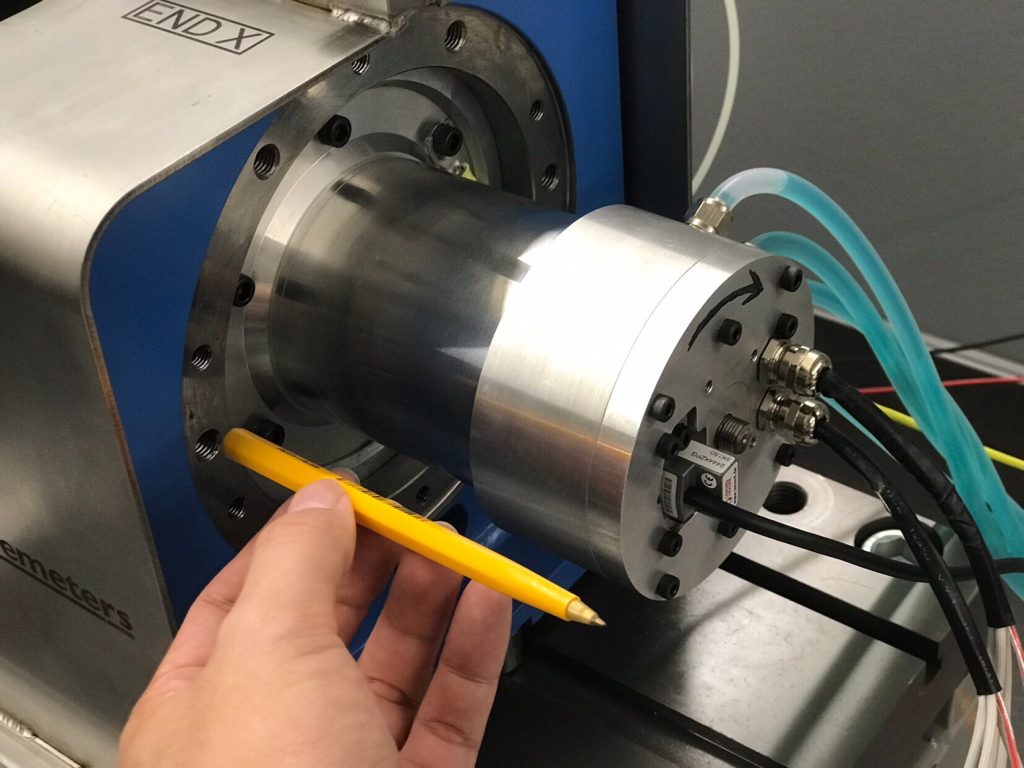

To build stronger iron bridges without reducing performance, Rukmi and her team drew inspiration from the longest railroad bridge in South Korea. Gyopo Bridge uses a ‘double arc’ technique to withstand very high loads. Rukmi’s team used this same concept to redesign the rotor’s iron bridges. “The result was amazing,” she says. “This motor can run up to 100,000 rpm and the power rating is 5 kilowatts. The motor is no longer than a pen, and the diameter is no bigger than a coffee mug. We designed one of the world’s fastest-turning IPMSMs using commonly used electrical steel lamination and permanent magnets.”

Rukmi’s team’s IPMSM rotor design, showing only one magnet pole; (b) Graphic of Gyopo Bridge, which uses a ‘double arch’ technique to withstand very high loads and was the inspiration behind Rukmi’s team’s design. © UNSW Power Electronics and Drive lab

What are the advantages of Rukmi’s new design?

In engineering, small changes in design can have considerable impacts. Rukmi’s new bridges allow the motor to reach a higher rpm without becoming damaged. This means the new machine can generate more power without needing more material.

Permanent magnet motors use rare-earth metals such as neodymium and dysprosium in their magnets to achieve high energy density and temperature resistance. These materials are rare, difficult to mine, and expensive to use. They are found in only a few countries, leading to issues with supply chains and resource conflicts. Extracting rare-earth metals is also damaging to the local environment. Rukmi’s motor uses less rare-earth metal to achieve better performance, lessening the demand for these materials. In addition, permanent magnet motors that rotate at 20,000 rpm or more, including IPMSMs, usually need a sleeve around the rotor to make it more robust. Designing and fitting this protective sleeve can be expensive and laborious. Even though it is the fastest IPMSM in the world, made with commercially available materials, Rukmi’s design is so mechanically strong that it does not need a protective sleeve.

Electric vehicle companies already use IPMSMs in their cars. Adopting Rukmi’s motor would be a simple switch, enabling electric cars to travel for longer before needing to be recharged. Even long-established technology like the electric motor can, and must, be reconsidered and improved by innovative researchers like Rukmi to achieve our goals of a sustainable, high-tech future.

Dr Rukmi Dutta

Dr Rukmi Dutta

Associate Professor

School of Electrical Engineering and Telecommunications, University of New South Wales, Sydney, Australia

Field of research: Electrical Engineering

Research project: Developing high-speed interior permanent magnet synchronous machines for electric vehicles

Funder: Australian Research Council (ARC)

ABOUT ELECTRICAL ENGINEERING

Broadly, electrical engineering is the design of devices and systems that use electricity or electromagnetism. These can be anything from computers to power stations. Even though electrical engineering is a mature discipline with many examples of well-developed technology, it remains an area of innovation, as existing electronics and machines are improved, and new ones are invented.

Generators and electric motors are core machines in electrical engineering. Generators transform energy, such as wind or nuclear energy, into electricity. Electric motors, in turn, convert the electricity into useful work, like rotating an axle or pumping water.

Generators and electric motors have been the foundation of the modern industrial economy since the 19th century, but researchers like Rukmi continue to develop innovations in their design, not only to improve performance and efficiency, but to make these technologies more environmentally friendly and sustainable.

What will the next generation of electrical engineers be doing?

As the world moves towards clean energy and electrification, electrical engineers will be increasingly in demand. Some areas where electrical engineering are needed include renewable energy, energy storage (i.e., batteries), the future power grid, electrification of transport, quantum computing, 5G-6G networks and robotics. Innovations like Rukmi’s contribute to the improved efficiency of electric cars and, potentially, electric aircraft. Other areas, like consumer electronics, are also constantly undergoing development.

What benefits can electrical engineering offer to the world?

Better electrical and electronic technology can make a big impact on quality of life for humans and other species on the planet. Electrical engineers can develop more efficient, less resource-intensive, and cheaper devices that will allow people around the world to access the benefits of electrification and the internet without harming the environment. Rukmi says,

“It is rewarding to know that, via my research, I am contributing in whatever small way towards clean energy and sustainable development for the future of humankind.”

Explore careers in electrical engineering

• UNSW Electrical Engineering and Telecommunications is the largest school of its kind in Australia. The school spans five research disciplines – Energy Systems, Telecommunications, Systems and Control, Nano/Micro Systems and Signal Processing. Similarly, most other universities that offer electrical engineering degrees also allow students to specialise in one of several disciplines.

• The world’s largest association for electrical engineers and other engineering disciplines is IEEE (www.ieee.org). IEEE hosts conferences, publishes peer-reviewed academic journals, offers networking opportunities, and has a student membership programme.

• A typical entry level electrical engineer earns around £35,000 in the UK, €60,000 in Germany, US$70,000- $80,000 in the USA, and AUD$50,000 in Australia. Salaries can be much higher, depending on experience and discipline, ranging up to $150,000+ in Australia.

Pathway from school to electrical engineering

• Key subjects at secondary and high school level are mathematics and physics.

• Most universities offer undergraduate degrees in electrical and/or electronic engineering, which are sometimes combined with computer science. Usually, a bachelor’s degree is enough to get a job as an electrical engineer in industry. Many companies have engineering or research departments that design new electrical or electronic products.

• Degrees or training programmes in electrical engineering often include an internship or apprenticeship with a company to acquire practical experience.

• Academic career paths are available for electrical engineers who, like Rukmi, want to work in fundamental design and innovation research. A PhD is required to become a university

Meet Rukmi

You have a bachelor’s degree and PhD in electrical engineering. Did you always know you wanted to be an electrical engineer?

Yes, to an extent. I wanted to be an engineer since I was in high school, even though an engineering career was not considered suitable for women. I was not any different from the other girls with whom I grew up, and neither did I have any particular talent for engineering, but I had a thirst for knowledge, and learning about new things always excited me. I was also an avid reader. I once wanted to read all the books in the district library, which was a two-floor building full of books!

How did where you grew up influence your career choice?

I grew up in Nagaon, a small sleepy town in the state of Assam in the north-east corner of India. It is a relatively remote place far away from the megacities of India. Assam is known for its natural beauty and resources, but in the 80s and 90s, it was infested with insurgency problems. Economic backwardness, low development and high unemployment were all around me when I was growing up. One of the most frustrating things in my childhood was routine power cuts in the evenings. In those days, I would say to myself, when I grow up, I will be an electrical engineer and solve this power cut problem forever. I was naïve to think I could solve all problems by myself, but it did influence my career choice.

You are a member of the Women in Engineering and Women in Research networks. Why are these networks important to you?

Engineering has a gender equity problem worldwide. There are very few successful women in engineering and research. The gender equity problem in electrical engineering is even more acute. IEEE’s Women in Engineering and UNSW’s Women in Research are valuable networks for me: I found mentors, role models and support among like-minded people.

What is the biggest risk you have taken and why?

There are actually two important risks that I took, and both allowed me to grow and become what I am today. The first risk was to move to a place more than a thousand kilometres away from my home state, where I joined a very large petrochemical industry as an electrical engineer – my first job. The second risk was moving to a completely different country in pursuit of higher education. I came to Australia to do my PhD, where I did not have any friends or family.

What is the biggest factor that has helped you be successful?

I believe hard work and persistence on my side, and support from family and mentors are the biggest factors. My parents never discriminated between my brother and me, and provided me with equal opportunities in all aspects, which I am grateful for. Then, in later years, it was my husband who supported me during my PhD and beyond. In my career development, I am grateful to my mentor, who was also my PhD supervisor. He exposed me to the joy of research, inventing new things and discovering new knowledge. My career at UNSW provided me with the academic freedom to pursue research that is close to my heart.

Rukmi’s top tips

1. Make sure you have a strong fundamental knowledge of mathematics and physics.

2. Have a thirst for knowledge!

3. The most important thing is hard work and persistence against all odds.

Do you have a question for Rukmi?

Write it in the comments box below and Rukmi will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)

My name is tochukwu currently a physics with electronics undergrad from Nigeria, I’m inspired by your feat.

I want to delve into engineering after my first degree, what route should I take?

Thank you

Hi Joseph,

I am glad to learn about interest in engineering. Physics with electronics as your first degree will certainly help. You can inquire with various universities that intake Physics gradutes in their Engineering Masters Programs. It will also be helpful if you can be participate in industry internship projects related to relevant Engieering field. If you would like to move towards research and development, explore possibility of doing thesis projects in your final year of the first degree.

Hi Professor Rukmi Dutta, I am Ahmed Ali Rachid and I wanted to know what is V=? and Current=? for the input of IPMSM Can you send me more details or information on the IPMSM, Please? like power, volt, current, more information about its design and I know that it can give extremly high speed over 100,000 RPM but can it give high torque for an example like heavy passenger Aircraft

Hi Ahmed,

The voltage and current of the lab prototype machine are 340V (line-line rms), 15A (rms), power is 5kW, and torque is 1Nm.

The motor can be scaled up for larger torque and power.

More details are available in a paper published recently at – https://ieeexplore.ieee.org/document/10075528

Can I get photo copies or brochure of your product. I am willing to buy one motor for my vehicle. I have converted my old scooter into electric scooter. But I am not satisfied with motor. I am looking for compact electric motor with high rpm & wattage. This motor must have foundation base & not side mounting installation. I have seen most of the motors are side face mounting. I need foundation base motor. So I humbly request you to send me any document which disclosed your product.

Thank you for this informative article on Electric Motors

Hello Rukmi,

I am interested in learning more about your improved interior permanent magnetic synchronous machine (IPMSM).

Specifically I am interested in leaning about:

1) the high speed and efficiency of your electric motor compared to other types of electric motors;

2) weight of the motor compared to other electric motors;

3) size and power rating (kW) of your motors;

4) typical applications your motor is best suited to.

I am an honours engineer and your work inspires me to improve and explore the application of high speed, low power, efficient electrical transport systems.

Thanks for your time reading my questions.

Kind Regards, Michael Herraman.

Hi Michael,

Thanks for your message to Prof. Dutta. We have been in contact and Prof. Dutta has indicated she’d reach out to you directly.

Kind Regards,

Futurum Webmaster.

Hello I am Lucas, here is my personal engineering project R+D (OPEN SOURCE) about how to make an Omndirectional electric motor / computer / robot / generator (FREE TO DOWNLOAD) (CAD: SOLIDWORKS 2020)

https://grabcad.com/library/360-electric-motor-concept-r-d-open-source-1