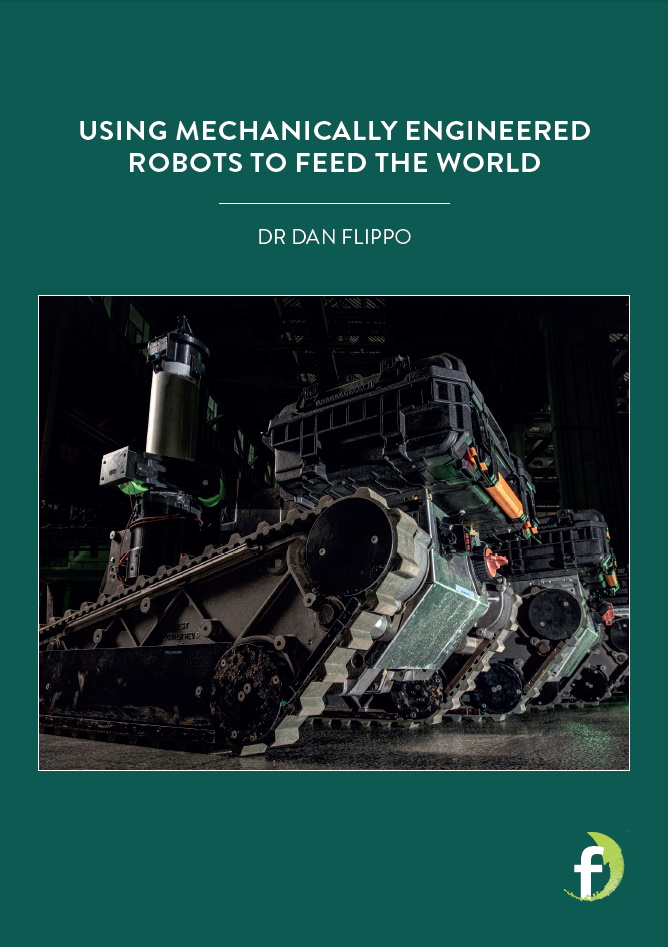

Using mechanically engineered robots to feed the world

Dr Dan Flippo is an associate professor at Kansas State University in the US. His laboratory, 2050RL, is trying to find technological solutions to sustainably feed more than 9 billion people by 2050 and beyond

According to the United Nations, the global population is expected to reach 9.8 billion by 2050. The growing number of people and increased levels of consumption mean that researchers around the world are working to develop practices that ensure there are enough resources for everyone. Importantly, these practices need to be sustainable, meaning that they can be kept going at a certain rate or level.

Clearly, one of the biggest challenges is going to be feeding the world. Current methods and technologies will become increasingly insufficient, so there is a real need to find new solutions. Dr Dan Flippo, an associate professor at Kansas State University in the US, leads a team that is trying to do just that. His laboratory – 2050 Robotics Laboratory (2050RL) – is working to find technological solutions, such as robotic vehicles, to feed more than 9 billion people in a sustainable way by 2050 and beyond.

HOW WILL ROBOTIC VEHICLES HELP TO SUSTAINABLY FEED THE WORLD?

Dan and his team are developing several robots at the same time, which can solve specific problems. Scouting robots will act as an aid to current farming production by looking for pests in the fields, spotting disease and predicting crop yield. One of Dan’s current projects uses scouting robots to look for aphids on sorghum, a type of grass and cereal grain plant. If aphids are spotted, the scouting robots will only spray pesticides on that plant.

This will save on the cost of chemicals and the overall environmental impact. Currently, food producers spray the entire crop. Then there is the problem of marginal land, which is land that is generally considered not good enough to plant crops. For instance, sloped land cannot be used to grow food because it cannot be farmed safely. Dan is using small robots to turn sloped land into arable land – land that is capable of being ploughed and used to grow crops. It is all about helping farmers to maximise the land they have.

The shortage of skilled labour is another challenge Dan’s lab is hoping to overcome. “A lack of skilled workers, coupled with time constraints is a real issue we are trying to solve,” explains Dan. “Small autonomous robots can be deployed in specific seasonal windows to cope with demand. These robots can work 24 hours per day and in much wetter conditions than conventional tractors can.”

WHAT ISSUES DOES THE TEAM HAVE TO CONSIDER WHEN DESIGNING THEIR ROBOTS?

Because the robots are much smaller than conventional tractors, there is not enough downforce or weight to plant or drill in the same way farmers do today. The team has therefore designed a powered tiller that cuts a furrow in the soil to put seeds in. These machines are controlled by a computer, so safety is a major concern. Fortunately, because the robots are so small, they are unlikely to hurt anybody if they accidentally hit them.

WHEN WILL DAN’S ROBOTIC VEHICLES BE WORKING IN FIELDS?

The process has been designed to work in stages, so that everything can be fine-tuned and any issues with safety and liability can be ironed out. It is expected that in the next five years or so, more and more scouting robots will be deployed in fields, while the drones and larger vehicles will start to be used a little later than that. Ultimately, it is hoped that autonomous, self-driving tractors will be commonplace in fields around the world.

The sustainable approach that Dan and his team are taking means they are working with ecologists and environmental scientists, rather than being in competition with them. Feeding the world of the future is a problem that will affect all of us in some way, so we all need to come together to find the best solutions we can.

DAN IS WORKING ON A VARIETY OF ROBOTIC VEHICLES.

EACH ONE HAS A DIFFERENT FUNCTION. HERE ARE SOME

EXAMPLES OF THE TYPES OF VEHICLES AND WHAT THEY

ARE DESIGNED TO DO.

WHEELCHAIR-SIZED ROBOTIC VEHICLES

Also known as AgDrones, these will carry out the agricultural work that tractors are usually responsible for, like digging trenches and planting seeds. They are much lighter than tractors, so they won’t sink in the mud in wet conditions – this means they can be used for longer and therefore plant more crops. They are also substantially cheaper than larger machines.

MICROWAVE-SIZED ROBOTIC VEHICLES

These robots are the ones that are most likely to get to market first. They include rovers that can use machine learning to detect pests; their small size enables them to easily fit between rows of crops, and they can generate a lot of useful information for farmers.

ROBOTIC VEHICLES WITH ELECTROMAGNETIC SENSORS

These robots, like the others, can perform repetitive tasks very well and without complaining! They can repeatedly drag an electromagnetic sensor over soil as crops are growing, which will provide information on how the soil changes as the crop grows. This information helps farmers to adapt their practices to make more food.

DR DAN FLIPPO

DR DAN FLIPPOAssociate Professor, Biological and Agricultural Engineering, Kansas State University, USA

FIELD OF RESEARCH: Biological and Agricultural Engineering

RESEARCH PROJECT: Dan’s goal is to combine state-of the-art robotic technology with food production methods to move towards sustainably feeding the world by 2050 and beyond.

FUNDERS: United States Department of Agriculture (USDA)

GRANT (undergrad)

GRANT (undergrad)

Grant is testing out different ways for a robot to see greenery versus soil. This is to stop the robotic vehicles running over green wheat, for example. He is using off-the-shelf light sensors, and testing them at different wavelengths, to see which sensor works the best in different light conditions, angles and distances.

LILLY (undergrad)

LILLY (undergrad)

Lilly is working on a robotic boat that can take water data. She is using sensors for temperature, turbidity (cloudiness) and depth. The boat also takes water samples and stores them. These data are used to better predict blue-green algae outbreaks.

SKYLAR (undergrad)

SKYLAR (undergrad)

Skylar is working out details for a new design of a DIN-Rail power meter for the robots. This meter makes it easier for the research team to read the voltage and current each motor uses.

CALVIN (master’s)

CALVIN (master’s)

Calvin is working on a robot that carries an electromagnetic sensor across the soil. Because of this sensor, this robot cannot have many metal parts, so Calvin must use carbon fibre and plastic.

HASIB (PhD)

HASIB (PhD)

Hasib is working on finding ways to help robots navigate through a field efficiently. How does a robot decide where to go and when? He also has to think about how to keep the robot charged or fill its containers with pesticide spray.

CHETAN (PhD)

CHETAN (PhD)

Chetan is working on the AgDrone to drill wheat in non-tilled soil, i.e. soil that has not been prepared for growing crops. He is also testing the AgDrone on different slopes and soil types so that an algorithm can use this data to come up with efficient ways to route the robots.

Reference

https://doi.org/10.33424/FUTURUM54

AgDrone vehicles in the 2050RL lab.

Credit: Jeff Moore, Kansas State University – Communications and Marketing

An AgDrone prototype used for cutting down trees.

Here’s an AgDrone with a wheat drill.

A caretaker bot, which is ready for a spray tank.

This bedframe robot carries the electromagnetic sensor.

This scumbot robot looks for blue-green algae.

Clearly, one of the biggest challenges is going to be feeding the world. Current methods and technologies will become increasingly insufficient, so there is a real need to find new solutions. Dr Dan Flippo, an associate professor at Kansas State University in the US, leads a team that is trying to do just that. His laboratory – 2050 Robotics Laboratory (2050RL) – is working to find technological solutions, such as robotic vehicles, to feed more than 9 billion people in a sustainable way by 2050 and beyond.

HOW WILL ROBOTIC VEHICLES HELP TO SUSTAINABLY FEED THE WORLD?

Dan and his team are developing several robots at the same time, which can solve specific problems. Scouting robots will act as an aid to current farming production by looking for pests in the fields, spotting disease and predicting crop yield. One of Dan’s current projects uses scouting robots to look for aphids on sorghum, a type of grass and cereal grain plant. If aphids are spotted, the scouting robots will only spray pesticides on that plant.

This will save on the cost of chemicals and the overall environmental impact. Currently, food producers spray the entire crop. Then there is the problem of marginal land, which is land that is generally considered not good enough to plant crops. For instance, sloped land cannot be used to grow food because it cannot be farmed safely. Dan is using small robots to turn sloped land into arable land – land that is capable of being ploughed and used to grow crops. It is all about helping farmers to maximise the land they have.

The shortage of skilled labour is another challenge Dan’s lab is hoping to overcome. “A lack of skilled workers, coupled with time constraints is a real issue we are trying to solve,” explains Dan. “Small autonomous robots can be deployed in specific seasonal windows to cope with demand. These robots can work 24 hours per day and in much wetter conditions than conventional tractors can.”

WHAT ISSUES DOES THE TEAM HAVE TO CONSIDER WHEN DESIGNING THEIR ROBOTS?

Because the robots are much smaller than conventional tractors, there is not enough downforce or weight to plant or drill in the same way farmers do today. The team has therefore designed a powered tiller that cuts a furrow in the soil to put seeds in. These machines are controlled by a computer, so safety is a major concern. Fortunately, because the robots are so small, they are unlikely to hurt anybody if they accidentally hit them.

WHEN WILL DAN’S ROBOTIC VEHICLES BE WORKING IN FIELDS?

The process has been designed to work in stages, so that everything can be fine-tuned and any issues with safety and liability can be ironed out. It is expected that in the next five years or so, more and more scouting robots will be deployed in fields, while the drones and larger vehicles will start to be used a little later than that. Ultimately, it is hoped that autonomous, self-driving tractors will be commonplace in fields around the world.

The sustainable approach that Dan and his team are taking means they are working with ecologists and environmental scientists, rather than being in competition with them. Feeding the world of the future is a problem that will affect all of us in some way, so we all need to come together to find the best solutions we can.

DAN IS WORKING ON A VARIETY OF ROBOTIC VEHICLES.

EACH ONE HAS A DIFFERENT FUNCTION. HERE ARE SOME

EXAMPLES OF THE TYPES OF VEHICLES AND WHAT THEY

ARE DESIGNED TO DO.

WHEELCHAIR-SIZED ROBOTIC VEHICLES

Also known as AgDrones, these will carry out the agricultural work that tractors are usually responsible for, like digging trenches and planting seeds. They are much lighter than tractors, so they won’t sink in the mud in wet conditions – this means they can be used for longer and therefore plant more crops. They are also substantially cheaper than larger machines.

MICROWAVE-SIZED ROBOTIC VEHICLES

These robots are the ones that are most likely to get to market first. They include rovers that can use machine learning to detect pests; their small size enables them to easily fit between rows of crops, and they can generate a lot of useful information for farmers.

ROBOTIC VEHICLES WITH ELECTROMAGNETIC SENSORS

These robots, like the others, can perform repetitive tasks very well and without complaining! They can repeatedly drag an electromagnetic sensor over soil as crops are growing, which will provide information on how the soil changes as the crop grows. This information helps farmers to adapt their practices to make more food.

DR DAN FLIPPO

DR DAN FLIPPO

Associate Professor, Biological and Agricultural Engineering, Kansas State University, USA

FIELD OF RESEARCH: Biological and Agricultural Engineering

RESEARCH PROJECT: Dan’s goal is to combine state-of the-art robotic technology with food production methods to move towards sustainably feeding the world by 2050 and beyond.

FUNDERS: United States Department of Agriculture (USDA)

GRANT (undergrad)

GRANT (undergrad)

Grant is testing out different ways for a robot to see greenery versus soil. This is to stop the robotic vehicles running over green wheat, for example. He is using off-the-shelf light sensors, and testing them at different wavelengths, to see which sensor works the best in different light conditions, angles and distances.

LILLY (undergrad)

LILLY (undergrad)

Lilly is working on a robotic boat that can take water data. She is using sensors for temperature, turbidity (cloudiness) and depth. The boat also takes water samples and stores them. These data are used to better predict blue-green algae outbreaks.

SKYLAR (undergrad)

SKYLAR (undergrad)

Skylar is working out details for a new design of a DIN-Rail power meter for the robots. This meter makes it easier for the research team to read the voltage and current each motor uses.

CALVIN (master’s)

CALVIN (master’s)

Calvin is working on a robot that carries an electromagnetic sensor across the soil. Because of this sensor, this robot cannot have many metal parts, so Calvin must use carbon fibre and plastic.

HASIB (PhD)

HASIB (PhD)

Hasib is working on finding ways to help robots navigate through a field efficiently. How does a robot decide where to go and when? He also has to think about how to keep the robot charged or fill its containers with pesticide spray.

CHETAN (PhD)

CHETAN (PhD)

Chetan is working on the AgDrone to drill wheat in non-tilled soil, i.e. soil that has not been prepared for growing crops. He is also testing the AgDrone on different slopes and soil types so that an algorithm can use this data to come up with efficient ways to route the robots.

ABOUT BIOLOGICAL AND AGRICULTURAL ENGINEERING

Dan started out as a mechanical engineer before becoming a biological and agricultural engineer. Mechanical engineering combines maths, science and technology to help build the world around us. From houses, factories, trains, planes and cars, through to bridges, space stations and even nanotechnologies, mechanical engineers are responsible for designing and developing the things on which we depend for our daily existence.

Agricultural engineers – or biological and agricultural engineers – work on a wide range of engineering activities, including in aquaculture (raising fish and other sea creatures for food), land farming and forestry. As a biological and agricultural engineer, you could easily be one of the most sought-after employees around!

WHAT SKILLS, KNOWLEDGE AND PERSONAL ATTRIBUTES DO YOU NEED TO BECOME A BIOLOGICAL AND AGRICULTURAL ENGINEER?

Dan’s team is very hands on, and they design and make most of the things they use in their research. “People on my team need to be good at design, fabrication and testing. They also need to program and be comfortable with the three aspects of mechatronics – programming, mechanical and electrical,” explains Dan. “It is also important to me that my team own their own projects and are not stopped by obstacles but instead work around them.”

ARE THERE MANY OPPORTUNITIES FOR STUDENTS WITH A DEGREE IN ENGINEERING IN THE US?

Yes, loads! A degree in mechanical engineering, for example, is one of the most versatile courses around because you can put your hand to the majority of engineering work out there. Dan has a mechanical engineering degree but works in the Biological and Agricultural Engineering Department at Kansas State University. Clearly there are a wide range of opportunities out there – it is all about the type of engineer you want to be.

DO YOU HAVE TO HAVE A DEGREE TO WORK IN THE FIELD?

“Anybody can engineer, but to get a job you will most likely need a degree,” says Dan. “If you want to own your own business, you will need a professional engineering licence, which is acquired after taking a test after college, then working for four years under a licensed engineer. You will then need to take a final test.”

Not many people appreciate how varied a career in engineering can be. Dan’s background is in mechanical engineering, but he now focuses on biological and agricultural engineering.

Zach Star has a few videos dedicated to the topic of mechanical engineering, including an explainer on what it is and some subfields and senior project examples, which should really give you a flavour for what to expect if you decide to study it.

According to PayScale, the average starting salary for an entry-level biological and agricultural engineer is $62,096, but you can earn considerably more as your skills and experience develop. It is important to study maths at school and college to become an engineer. Machine design, dynamics, CAD design, engineering and even English are also useful subjects.

HOW DID DR DAN FLIPPO BECOME A BIOLOGICAL AND AGRICULTURAL ENGINEER?

DID YOU IMAGINE YOURSELF WORKING WITH ROBOTS AND IN AN AGRICULTURAL SETTING WHEN YOU WERE YOUNGER?

Not at all! I wanted to be a professional ‘taker-apart-er’. My parents weren’t sure whether that was even a thing, but taking things apart was what brought me the most joy as a kid. I enjoyed seeing how things worked inside. Unfortunately, for my parents, after I had worked out what happened inside, I didn’t have much interest in putting anything back together again!

YOU HAVE A BS DEGREE, MASTER’S AND PHD IN MECHANICAL ENGINEERING. WHO OR WHAT DREW YOU THIS SUBJECT?

My parents actually suggested it – they realised I liked all things mechanical and designing my own machines. After my degree, I worked at Cessna Aircraft company, then went to China for two years to work as an international business intern. When I came back, I stayed at Cessna while I got my master’s degree in mechanical engineering with robots. After that, I left Cessna and decided to do my doctoral work in the same subject, although the specific focus was on planetary exploration.

After graduating, I programmed large tractors for two-and-a-half years, then came to Kansas State University to join the Biological and Agricultural Engineering Department’s Machinery Group. Our role is to study and design all off-road vehicles, including robots for agricultural use.

WHAT IS IT THAT EXCITES YOU ABOUT THE RESEARCH YOU ARE INVOLVED WITH?

Short term, what excites me is making things – like robots, machines and other creations. It is like having access to a huge set of LEGO that you can use to make new things all the time. In the longer term, I feel there is a certain nobility in feeding the world – and I really do foresee problems in the future if we do not put measures in place. I am hopeful that my research will make valuable contributions to finding solutions.

SOME PEOPLE FEAR THAT ROBOTS WILL PUT PEOPLE OUT OF JOBS. WHAT WOULD YOU SAY TO PEOPLE WHO HAVE THIS FEAR?

While I can understand some of the fears that people have, it is worth remembering that using robotics in agriculture is increasingly necessary, not least because there is such a labour shortage in America. There is also the fact that robots can be used in dangerous situations – they can go where humans cannot – and this helps save people’s lives.

Chetan didn’t think that this robot would be able to tow Dan’s 5,000 lb SUV. So, they hooked it up and it did. Dan is in the car; Chetan is taking the video. They are at the stadium parking lot in Manhattan, Kansas, and are testing out a new navigation algorithm.

DAN’S TOP TIPS

1. Never be afraid to fail. ‘Fail early and fail often’ is a motto that my team uses. Failing is learning! It can be difficult when you fail, but it is what you do with that failure that is the important thing. It can be a brilliant career that you can do some good with, so learn from your failures and be noble in your successes.

2. IQ (and/or natural intelligence) is not the most important thing in your studies – the important thing is to work hard. I have never felt that smart, but I love to learn. Doing the best with what you have is a cliché, but it is solid advice.

3. Study maths any chance you get! Take things apart and see if you can understand how they work. Use items around the house (ask your parent’s permission of course!) or the hardware store to be inspired. Look for parts that can be used to make machines. Lego is a brilliant resource and you should always have some in the house!