What if we could repair wind turbines with aerospace engineering and computer science?

Dr Marianna Maiaru is part of the WindSTAR Center at the University of Massachusetts Lowell in the US. She is using her expertise in aerospace engineering to understand how to repair damaged wind turbine blades in the shortest possible time

The consumption of fossil fuels is warming the planet and it is no exaggeration to say that the effects will be cataclysmic unless more work is done to reduce global carbon emissions. In recent years, attention has turned to renewable energy as a means of reducing emissions and our reliance on fossil fuels. Renewable energy can be broadly defined as that which is generated through wind, solar and hydro power, and companies around the world are working to increase the amount of homes and buildings that are powered by sustainable electricity. Wind turbines are one example of how companies are turning wind into clean electricity.

Wind turbines work by extracting energy from the wind, causing the blades to rotate when wind hits them. This spinning motion turns a shaft to generate kinetic energy, which is then converted to energy that we can use. The process is efficient – most onshore wind turbines in the UK can produce more than 6 million kilowatt hours of electricity every year – enough to meet the electricity demands of approximately 1,500 households. In the US, from January through December of 2019, 7.29% of all electrical energy was generated by wind power. That same year, wind power surpassed hydroelectric power as the largest renewable energy source.

However, like most machines, wind turbines can be damaged during their operations and when they do, they need to be shut down for repair. This means they cannot produce electricity for the length of time it takes to solve the issue. It is therefore important to find ways to repair wind turbines quickly to get them up and running again. Dr Marianna Maiaru, based at the WindSTAR Center at the University of Massachusetts Lowell, is using her expertise in aerospace engineering to work on finding out how to do just that.

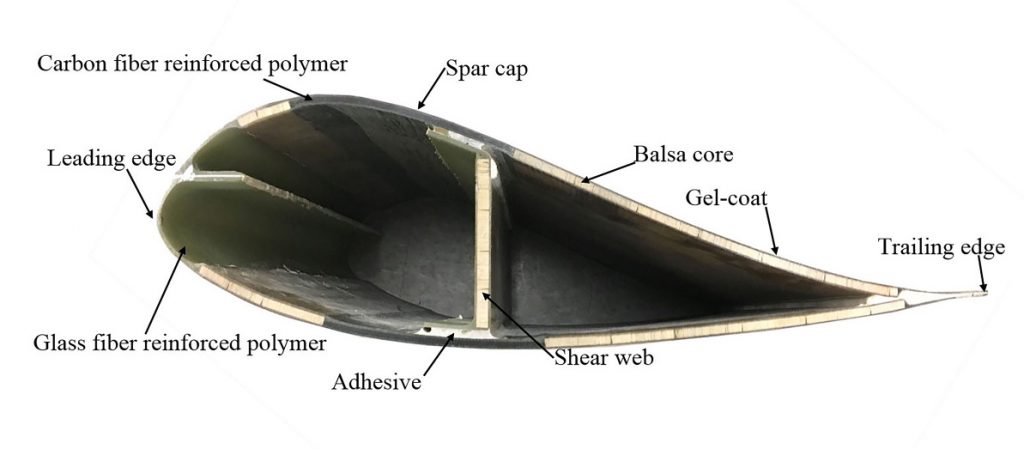

Check out this cross-section of a wind turbine blade. Lots of factors need to be considered in its design, whether it is the materials it is made from or its streamlined shape. Credit: WindSTAR Center

WHAT ARE THE SPECIFIC AIMS OF MARIANNA’S PROJECT?

The main objective of Marianna’s project is to understand how best to repair a damaged wind turbine blade in the shortest time. Wind blades are designed using many different materials and many events can occur that cause damage. If the damaged materials are exposed to wind and rain for too long, they can be damaged further and make the problem even worse – repairing bigger damages takes longer and costs more money. “If the size of the repair is manageable, repair companies send people up-tower to perform the repair. When that happens, the wind turbine has to be shut down, which means that it cannot produce energy,” explains Marianna. “It is therefore important to understand when it is the best time to perform the repair and how to do it in the shortest time.”

WHAT CHALLENGES IS MARIANNA HOPING TO ADDRESS?

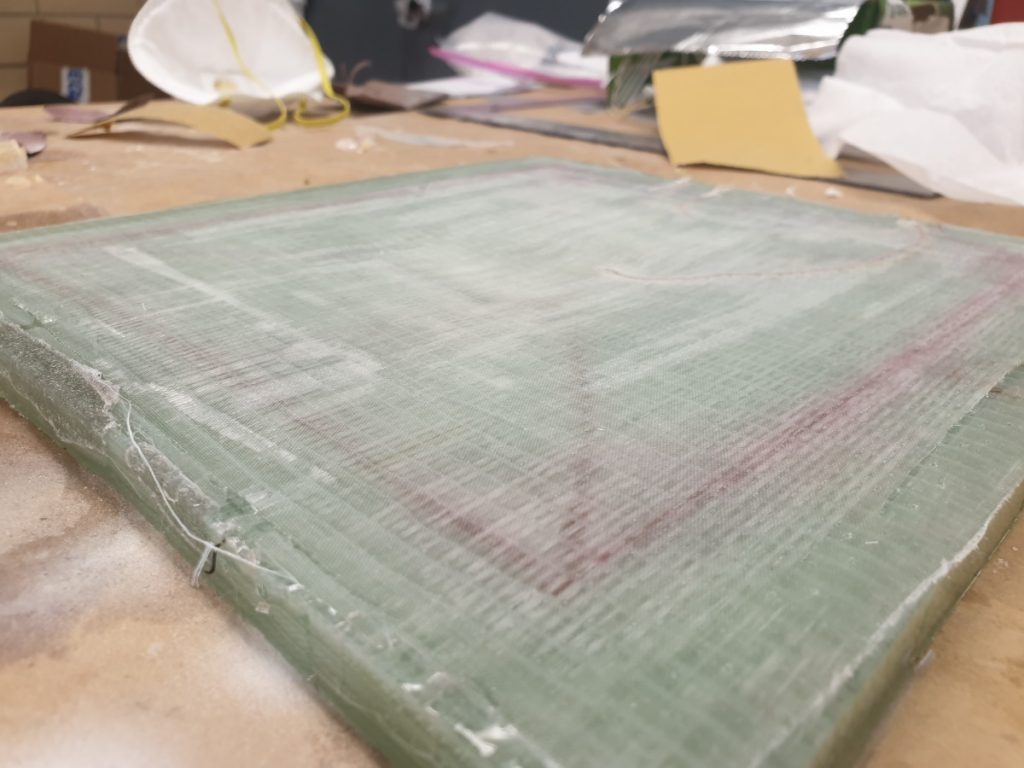

Every repair is different, so it is challenging to create a universal solution to the problem. Wind blades can be made from fibre-reinforced composite materials, balsa wood and adhesives. Glass fibres, kept together by a polymeric ‘glue,’ are used for the most part in composites for wind blades. “It is not easy to understand how the liquid ‘glue’ solidifies during the repair, and then we need to understand the effect of all the other materials around the polymer, including the balsa wood, and the composite laminate that was exposed to different weather conditions before the repair,” says Marianna. “Then, because every repair looks different, we need a tool that can predict the outcome of the repair. This would allow us to understand the most essential parameters to efficiently repair the blade.”

HOW IS THE TEAM CONDUCTING ITS RESEARCH?

The first thing Marianna’s team does is study and observe, before discussing the issues and current solutions with industry. Once a clear understanding of the problem they want to solve has been achieved, the researchers create a simplified model using maths and, when the simpler model works, add details, one at a time, until they are describing the problem in all its complexity. “Once we have the completed model, we try to recreate repairs in the lab to make sure we have captured the correct physics and that our model is working as it should,” explains Marianna. “If we don’t know how the material behaves, we study the material in the lab.”

Reference

https://doi.org/10.33424/FUTURUM69

Academic studies can be difficult, but you should always remember to try and make the work fun, like these students at the University of Massachusetts Lowell.

Wind blades can be made from fibre reinforced composite materials, balsa wood and adhesives. In this image, glass fibres, kept together by a polymeric‘ glue,’ are used for the most part in composites for wind blades.

The consumption of fossil fuels is warming the planet and it is no exaggeration to say that the effects will be cataclysmic unless more work is done to reduce global carbon emissions. In recent years, attention has turned to renewable energy as a means of reducing emissions and our reliance on fossil fuels. Renewable energy can be broadly defined as that which is generated through wind, solar and hydro power, and companies around the world are working to increase the amount of homes and buildings that are powered by sustainable electricity. Wind turbines are one example of how companies are turning wind into clean electricity.

Wind turbines work by extracting energy from the wind, causing the blades to rotate when wind hits them. This spinning motion turns a shaft to generate kinetic energy, which is then converted to energy that we can use. The process is efficient – most onshore wind turbines in the UK can produce more than 6 million kilowatt hours of electricity every year – enough to meet the electricity demands of approximately 1,500 households. In the US, from January through December of 2019, 7.29% of all electrical energy was generated by wind power. That same year, wind power surpassed hydroelectric power as the largest renewable energy source.

However, like most machines, wind turbines can be damaged during their operations and when they do, they need to be shut down for repair. This means they cannot produce electricity for the length of time it takes to solve the issue. It is therefore important to find ways to repair wind turbines quickly to get them up and running again. Dr Marianna Maiaru, based at the WindSTAR Center at the University of Massachusetts Lowell, is using her expertise in aerospace engineering to work on finding out how to do just that.

WHAT ARE THE SPECIFIC AIMS OF MARIANNA’S PROJECT?

The main objective of Marianna’s project is to understand how best to repair a damaged wind turbine blade in the shortest time. Wind blades are designed using many different materials and many events can occur that cause damage. If the damaged materials are exposed to wind and rain for too long, they can be damaged further and make the problem even worse – repairing bigger damages takes longer and costs more money. “If the size of the repair is manageable, repair companies send people up-tower to perform the repair. When that happens, the wind turbine has to be shut down, which means that it cannot produce energy,” explains Marianna. “It is therefore important to understand when it is the best time to perform the repair and how to do it in the shortest time.”

WHAT CHALLENGES IS MARIANNA HOPING TO ADDRESS?

Every repair is different, so it is challenging to create a universal solution to the problem. Wind blades can be made from fibre-reinforced composite materials, balsa wood and adhesives. Glass fibres, kept together by a polymeric ‘glue,’ are used for the most part in composites for wind blades. “It is not easy to understand how the liquid ‘glue’ solidifies during the repair, and then we need to understand the effect of all the other materials around the polymer, including the balsa wood, and the composite laminate that was exposed to different weather conditions before the repair,” says Marianna. “Then, because every repair looks different, we need a tool that can predict the outcome of the repair. This would allow us to understand the most essential parameters to efficiently repair the blade.”

HOW IS THE TEAM CONDUCTING ITS RESEARCH?

The first thing Marianna’s team does is study and observe, before discussing the issues and current solutions with industry. Once a clear understanding of the problem they want to solve has been achieved, the researchers create a simplified model using maths and, when the simpler model works, add details, one at a time, until they are describing the problem in all its complexity. “Once we have the completed model, we try to recreate repairs in the lab to make sure we have captured the correct physics and that our model is working as it should,” explains Marianna. “If we don’t know how the material behaves, we study the material in the lab.”

DOES THE RESEARCH INVOLVE COMPUTER SIMULATIONS?

Yes – the models that Marianna and the team create are implemented in computer simulations. “Simulations are a great tool for engineering because they can reduce the cost and time of the engineering processes. Through modelling we can understand the effect of all the relevant parameters, one at a time,” explains Marianna. “For example, once the method to study wind blade repairs will be ready, we will be able to study a lot of different repair geometry in a very effective way.” Computing is an important skill to becoming an engineer because of how much it benefits the research you will be doing.

HOW IS THE RESEARCH GOING AND WHAT ARE THE NEXT STEPS?

The project is going well so far and the team has done lots of material characterisation for different polymer systems that imply different repair procedures. “We have studied the effect of different parameters on the repair outcome to reproduce environmental conditions that simulate the weather in a range of places from Iowa to Texas,” says Marianna. “We have created different models, some very accurate, others simplified, and now we are in the process of validating them.” Marianna and her team will look at other material systems and more complex repair configurations in the future. Ultimately, the work will ensure that wind turbines are repaired in the shortest amount of time possible, so that they can start generating renewable energy to power homes across the United States.

ABOUT THE WINDSTAR CENTER

The WindSTAR Center is the only National Science Foundation sponsored Industry-University Cooperative Research Center in the US devoted to wind energy research. It is made up of a team of academics from the University of Massachusetts Lowell, University of Texas at Dallas and experts from industry, all of whom have unique expertise and capabilities that help them conduct research to advance wind turbine science and systems. The interdisciplinary group focus on wind turbine manufacturing, reliability, energy storage, monitoring, controls, simulation, and design, and look at various themes, from building wind turbine blades to generating power and integrating electricity with the grid.

WHAT TYPE OF PROJECTS ARE CURRENTLY HAPPENING AT THE CENTER?

There are currently around 10 projects at the WindSTAR Center. Some of the problems researchers are trying to solve include studying specific components of wind blades, such as the adhesive and balsa core. Other projects are focused on ways to use aerodynamics and extract power from the wind in more efficient ways, and there are also investigations looking at how to use different sensors to predict blade conditions and to detect damage.

WHY IS THE CENTER COLLABORATING WITH THE UNIVERSITY OF TEXAS AT DALLAS AND EXPERTS FROM INDUSTRY?

The objective of the WindSTAR Center is to utilise innovative research capabilities to develop high-impact solutions to key industry challenges. “The WindSTAR Center is a great infrastructure because it brings together people with different expertise that want to improve the wind energy sector,” explains Marianna. “It also keeps the research very focused on the actual need that the industry and wind turbines owner and operators have.”

DOES THE CENTER OFFER ANY PUBLIC OUTREACH SCHEMES FOR SCHOOLS AND/OR YOUNG PEOPLE?

Yes! Many of the outreach activities are focused on introducing (middle school) K12 students to the basics of wind energy production. “We want to engage students with diverse backgrounds in the design and manufacture of wind turbine components that examine aerodynamics, foundations, towers, generators, gear boxes, blades, composite materials and beam-blade structures for wind energy applications,” says Marianna.

DR MARIANNA MAIARU

DR MARIANNA MAIARU

Assistant Professor, Francis College of Engineering, University of Massachusetts Lowell, USA

FIELD OF RESEARCH: Wind Energy, Aerospace Engineering, Computational Mechanics

RESEARCH PROJECT: Marianna is working on a project that seeks to understand how to best repair a damaged wind turbine blade in the shortest time. The findings will help prevent the need to shut wind turbines down for long periods

DR MARIANNA MAIARU

DR MARIANNA MAIARU

Assistant Professor, Francis College of Engineering, University of Massachusetts Lowell, USA

FIELD OF RESEARCH: Wind Energy, Aerospace Engineering, Computational Mechanics

RESEARCH PROJECT: Marianna is working on a project that seeks to understand how to best repair a damaged wind turbine blade in the shortest time. The findings will help prevent the need to shut wind turbines down for long periods

MEET SAGAR SHAH, PHD STUDENT

Sagar Shah is one of Marianna’s PhD students who is currently in the third year of a PhD programme in the Department of Mechanical Engineering at the University of Massachusetts Lowell. We caught up with him to understand more about his studies and what motivates him.

Sagar Shah is one of Marianna’s PhD students who is currently in the third year of a PhD programme in the Department of Mechanical Engineering at the University of Massachusetts Lowell. We caught up with him to understand more about his studies and what motivates him.

CAN YOU TALK ABOUT YOUR ROLE AT THE WINDSTAR CENTER?

My role is to conduct fundamental studies to understand the effect of the manufacturing process on materials used in wind turbine blades, facilitate the design of longer and lighter blades, and optimise the repair of damaged blades through experimentation and finite element methods (using maths to understand and quantify physical phenomena). Our group works closely with many wind blade manufacturers, owners and operators to understand the repair process requirement for damaged blades and provide insight for on-field repair optimisation.

WHAT EXCITES YOU ABOUT WORKING IN THE WIND ENERGY SECTOR?

I enjoy the in-depth learning of composite materials and wind blade manufacturing, coupled with hands-on experimentation and computational modelling. I find these aspects particularly exciting.

WHY SHOULD YOUNG PEOPLE CONSIDER WORKING IN THIS SECTOR?

Well, wind energy is a vastly established field, with roots going back to hundreds of years. With the advent of lightweight composite materials in large structural applications – and the need for sustainable resources for power generation – the wind energy sector has gained huge momentum in the last few decades. Off-shore wind turbines are also gaining importance due to the high demand for sustainable power that needs to be delivered close to load centres near the coast.

Young professionals will have a vast range of opportunities within the wind energy sector that would not only align with their interests, but also provide a sense of responsibility that they are doing their part for the environment and striving towards a sustainable future. It got my attention and I hope it will get yours too!

HOW TO BECOME INVOLVED IN WIND ENERGY

• The US Department of Energy has loads of useful information on wind markets, including research and development projects and job opportunities.

• The American Wind Energy Association is the voice of wind energy in the US. Read through the site for further information on the opportunities within the field.

• In 2018, wind turbine technicians earned a median salary of $54,370, according to US News.

• According to salary.com, the average salary for an engineer in the United States is between $63,790 and $155,860.

• Check out the WindSTAR webpage for ideas on what a career in wind energy could look like: https://www.uml.edu/Research/Windstar/default.aspx

Marianna recommends starting with maths, physics and chemistry. Of course, any subjects related to energy generation will be a big help, particularly those that are centred on sustainable or renewable energy, such as wind.

HOW DID DR MARIANNA MAIARU BECOME A WIND ENERGY ENGINEER?

YOU HAVE A BS, MS AND PHD IN AEROSPACE ENGINEERING. DID YOU ALWAYS KNOW THAT YOU WANTED TO GET INTO THIS FIELD WHEN YOU WERE YOUNGER?

I have always been a curious person. I was particularly fascinated by flight mechanics and space exploration. My favourite topics in school were physics and maths – I loved physics because it really helped explain how things around me worked. At the end of high school, I was conflicted between going into astrophysics or aerospace engineering. I am glad that I went into aerospace engineering because that career helped to build a problem-solving mindset. Time helped me to confirm my choice because I realised how satisfying it can be to bring a project to completion, build new structures, and understand how new things work.

Aerospace engineering is a very broad field and you get to explore a lot of topics. I found that I wanted to build structures that can fly and go into space, which is why I ended up specialising in composites. I enjoyed my studies very much, and that made me realise I was on the right path.

WHO OR WHAT INSPIRED YOU TO STUDY AEROSPACE ENGINEERING?

I was lucky to be exposed to engineering very early in life. My dad is an electrical engineer and I spent a lot of time following him around to project sites. I saw how he would build houses and other infrastructures. The logic that he used to solve problems, and the problems themselves, were very inspiring for a young girl. He educated me to think critically.

WHY HAVE YOU TURNED YOUR ATTENTION TO WIND ENERGY?

Wind and aerospace are my two main passions. I work a lot in aerospace, but composites are very versatile, and all that we learn from aerospace can be applied to other fields. The work, knowledge and passion of some of the members at the WindSTAR Center inspired me to focus even more on renewables. The work is technically challenging and working with the sponsors of our projects is very rewarding, in that we can see the impact of our findings.

AS A FEMALE ENGINEER, HAVE YOU EVER FELT AT A DISADVANTAGE?

I would say that I am an engineer, a woman, and a lot of other things. Professionally and academically speaking, I have never felt different to my peers. Engineers are curious people, and I have always been determined to find answers to my questions. Being an engineer is a commitment to finding new solutions. Engineering is an absolutely fascinating field and very rewarding. It has nothing to do with gender, ethnicity, or any other human characteristic. The only things that matter are your interests, commitment, hard work and curiosity. There is no need to impose limits based on gender stereotypes. I have not done it to myself and I teach my students not to do so, either. Unfortunately, there are not many women in engineering, especially in aerospace.

SO, WOULD YOU RECOMMEND A CAREER IN ENGINEERING?

Absolutely. There is a lot of reward in making things work and understanding how they break!

MARIANNA’S TOP TIPS

01 Finding a mentor is the most valuable step that any student can take. A mentor can help with your direction, provide advice when you need it and give you an example to follow.

02 Academic studies can be difficult, but you should always remember to try and make the work fun. If you can achieve that, you will be able to appreciate how productive and interesting what you do is, which should help accelerate the learning process. Hands-on activities are always fun and very instructive!

03 Modern engineering requires a team effort. You should do your best to learn how to work independently, but also how to work with other people. These are skills that you need to try and cultivate from the very beginning of your career.