Out with a bang: the challenge of measuring explosions

Explosions are difficult to study because they happen so quickly and with such destructive power. Yet knowing how they work is important for protecting human lives. So, a team of engineers at the University of Sheffield, UK, have established the Blast and Impact Diagnostics Lab, where they use the latest tech and experimental techniques to learn more about what happens when stuff blows up

TALK LIKE AN ENGINEER

EXPLOSION – a sudden catastrophic release of energy, causing a pressure wave

LOAD – a force, deformation or acceleration applied to something, such as a structure

PRESSURE WAVE or BLAST WAVE – when a disturbance causes a change in pressure emanating outwards from a source

SENSOR – a device that measures physical properties, such as light, heat or pressure

Though we all instinctively know an explosion when we see one, the physical processes behind them are pretty complex. “Explosions happen when a lot of trapped energy is suddenly released,” explains Dr Sam Clarke, a civil engineer at the University of Sheffield. This energy creates a pressure wave, expanding outwards from the site of detonation, and it is this pressure wave that causes damage to people and infrastructure.

His colleague Dr Sam Rigby, also a civil engineer, explains in more detail. “An explosion is a chemical reaction that converts an explosive material into a high-pressure, highly dense gas,” he says. “This gas then rapidly expands and violently forces the air surrounding the explosive out of the way.”

Understanding this process in more detail can help engineers predict the effects that explosions will have on structures, which is why Sam and Sam have established the Blast and Impact Diagnostics Lab. If engineers know how structures will respond to explosions, then safety measures can be improved to hopefully ensure lives are saved during future blasts.

STRONG BUT SENSITIVE

The trouble is, explosions are very hard to measure. “You need equipment that can record intense pressures (many times stronger than steel) which are applied and removed in a miniscule amount of time (less than a thousandth of a blink of an eye),” says Sam R. This requires equipment that is both robust enough to survive the explosion but sensitive enough to record these very rapid changes in conditions.

Traditionally, the pressure of explosions has been measured from further away or averaged out over a larger surface area, which does not give much information about the precise goings-on within the explosion itself. The Blast and Impact Diagnostics Lab is hoping to change this, and so the team is designing bespoke apparatus to measure explosions, providing fundamental insights into the physical processes that occur extremely close to an explosive.

As well as measuring explosions themselves, the team is also interested in their effects on nearby structures. “To design structures that are more resilient to explosions, we have to understand the loads they are exposed to,” says Sam R. So, experiments are being conducted in the lab to investigate how structures respond to the loading caused by an explosive blast wave.

MEASURING THE BIG BANG

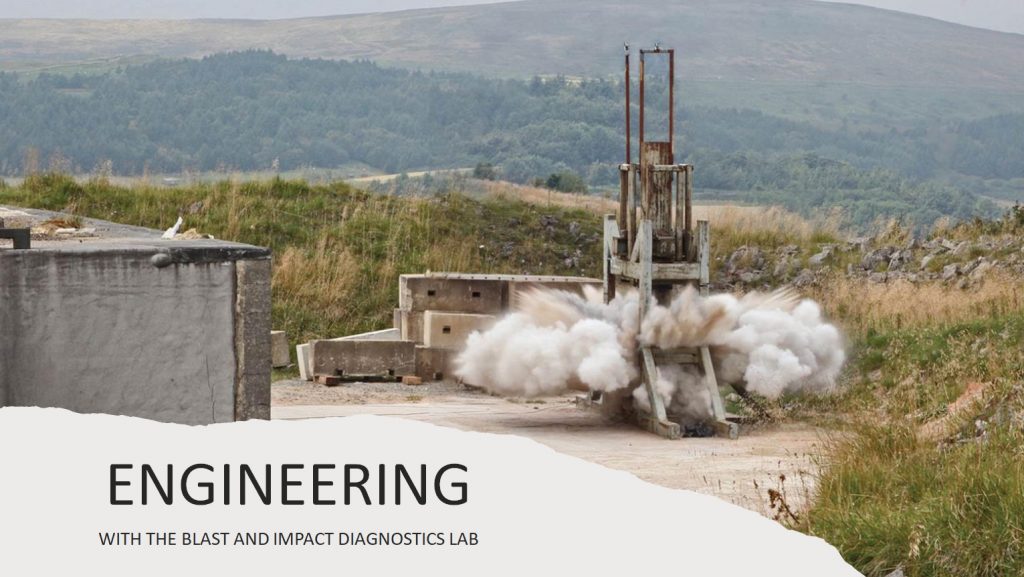

To conduct an explosion, the team uses plastic explosives. “These high explosives have about the same energy in them as a Mars Bar,” says Sam C. “The difference is that you can’t detonate a Mars Bar!” Once the explosives have been moulded to the desired shape, a detonator is added then the firing pack is activated.

“We clear the area and give a warning on-site before the actual detonation happens,” says Professor Genevieve Langdon, a professor of blast and impact engineering. “That’s the simple bit. The tricky bit is measuring what happens!” The team uses an array of sensors, all of which must survive the explosion and take accurate recordings at the same time.

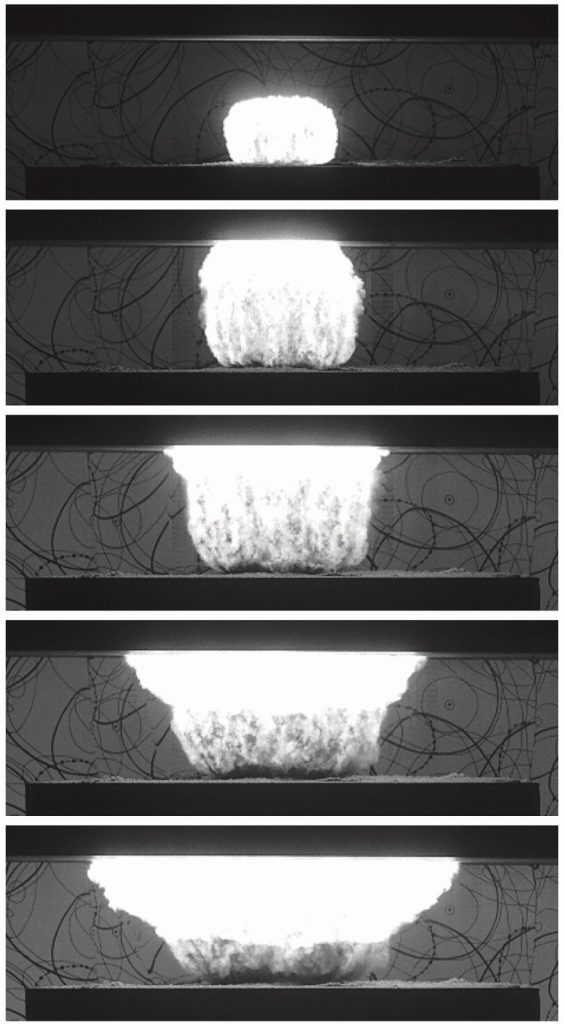

Ultra-high-speed cameras film the event, collecting up to a million photos per second. These images show how the blast waves develop during the explosion and how any structures in the path of the explosion react to the expanding pressure wave. The explosion is also filmed by cameras that can observe qualities not visible to the naked eye. Infrared cameras measure temperature changes during the explosion while X-ray cameras allow the team to see inside the explosive event.

Pressure gauges measure the pressure applied by the blast wave itself – the rapidly moving air caused by the expansion of gas within the explosive. “This pressure load will exert a hard ‘push’ on a structure, like a very intense wind, which can cause the structure to deform or break,” says Sam R. By studying the magnitude of this pressure loading at different distances from the source of detonation, the team will learn how much pressure buildings in the path of an explosion will be subjected to.

EXPLOSIONS IN THE REAL WORLD

Lives and structures are most at risk from explosions in warzones. The team hopes their findings could help protect soldiers from improvised explosive devices, such as roadside bombs. “We’ve been able to identify the properties of soil types which affect how dangerous a buried explosive may be,” says Sam C. “Next we will try to understand why these properties affect the explosion, which is where the new lab comes in.”

Sometimes, explosions happen on a massive scale, such as the tragic explosion in Beirut in August 2020. Obviously, explosions at this scale cannot be replicated in a lab – but that does not mean they cannot be studied. “Blast waves scale quite nicely according to ‘cube root’ scaling,” says Sam R. “This means the properties of a small and large explosion will be the same, just scaled according to their size.” Small-scale explosions conducted in the lab can therefore be scaled up to help understand city-scale explosions such as the Beirut blast. However, the blast wave of ‘real-life’ explosions will interact with structures such as buildings, and so the next step for the team is to understand how the expanding pressure wave will be influenced by obstacles.

While the team certainly enjoy the excitement of creating explosions for their experiments (“Of course it’s fun to blow stuff up!” says Andy, a technician in the lab), the work conducted in the Blast and Impact Diagnostics Lab has a much greater purpose and will ultimately help save lives and protect infrastructure from the devastating effects of explosions.

Reference

https://doi.org/10.33424/FUTURUM192

EXPLOSION – a sudden catastrophic release of energy, causing a pressure wave

LOAD – a force, deformation or acceleration applied to something, such as a structure

PRESSURE WAVE or BLAST WAVE – when a disturbance causes a change in pressure emanating outwards from a source

SENSOR – a device that measures physical properties, such as light, heat or pressure

Though we all instinctively know an explosion when we see one, the physical processes behind them are pretty complex. “Explosions happen when a lot of trapped energy is suddenly released,” explains Dr Sam Clarke, a civil engineer at the University of Sheffield. This energy creates a pressure wave, expanding outwards from the site of detonation, and it is this pressure wave that causes damage to people and infrastructure.

His colleague Dr Sam Rigby, also a civil engineer, explains in more detail. “An explosion is a chemical reaction that converts an explosive material into a high-pressure, highly dense gas,” he says. “This gas then rapidly expands and violently forces the air surrounding the explosive out of the way.”

Understanding this process in more detail can help engineers predict the effects that explosions will have on structures, which is why Sam and Sam have established the Blast and Impact Diagnostics Lab. If engineers know how structures will respond to explosions, then safety measures can be improved to hopefully ensure lives are saved during future blasts.

STRONG BUT SENSITIVE

The trouble is, explosions are very hard to measure. “You need equipment that can record intense pressures (many times stronger than steel) which are applied and removed in a miniscule amount of time (less than a thousandth of a blink of an eye),” says Sam R. This requires equipment that is both robust enough to survive the explosion but sensitive enough to record these very rapid changes in conditions.

Traditionally, the pressure of explosions has been measured from further away or averaged out over a larger surface area, which does not give much information about the precise goings-on within the explosion itself. The Blast and Impact Diagnostics Lab is hoping to change this, and so the team is designing bespoke apparatus to measure explosions, providing fundamental insights into the physical processes that occur extremely close to an explosive.

As well as measuring explosions themselves, the team is also interested in their effects on nearby structures. “To design structures that are more resilient to explosions, we have to understand the loads they are exposed to,” says Sam R. So, experiments are being conducted in the lab to investigate how structures respond to the loading caused by an explosive blast wave.

MEASURING THE BIG BANG

To conduct an explosion, the team uses plastic explosives. “These high explosives have about the same energy in them as a Mars Bar,” says Sam C. “The difference is that you can’t detonate a Mars Bar!” Once the explosives have been moulded to the desired shape, a detonator is added then the firing pack is activated.

“We clear the area and give a warning on-site before the actual detonation happens,” says Professor Genevieve Langdon, a professor of blast and impact engineering. “That’s the simple bit. The tricky bit is measuring what happens!” The team uses an array of sensors, all of which must survive the explosion and take accurate recordings at the same time.

Ultra-high-speed cameras film the event, collecting up to a million photos per second. These images show how the blast waves develop during the explosion and how any structures in the path of the explosion react to the expanding pressure wave. The explosion is also filmed by cameras that can observe qualities not visible to the naked eye. Infrared cameras measure temperature changes during the explosion while X-ray cameras allow the team to see inside the explosive event.

Pressure gauges measure the pressure applied by the blast wave itself – the rapidly moving air caused by the expansion of gas within the explosive. “This pressure load will exert a hard ‘push’ on a structure, like a very intense wind, which can cause the structure to deform or break,” says Sam R. By studying the magnitude of this pressure loading at different distances from the source of detonation, the team will learn how much pressure buildings in the path of an explosion will be subjected to.

EXPLOSIONS IN THE REAL WORLD

Lives and structures are most at risk from explosions in warzones. The team hopes their findings could help protect soldiers from improvised explosive devices, such as roadside bombs. “We’ve been able to identify the properties of soil types which affect how dangerous a buried explosive may be,” says Sam C. “Next we will try to understand why these properties affect the explosion, which is where the new lab comes in.”

Sometimes, explosions happen on a massive scale, such as the tragic explosion in Beirut in August 2020. Obviously, explosions at this scale cannot be replicated in a lab – but that does not mean they cannot be studied. “Blast waves scale quite nicely according to ‘cube root’ scaling,” says Sam R. “This means the properties of a small and large explosion will be the same, just scaled according to their size.” Small-scale explosions conducted in the lab can therefore be scaled up to help understand city-scale explosions such as the Beirut blast. However, the blast wave of ‘real-life’ explosions will interact with structures such as buildings, and so the next step for the team is to understand how the expanding pressure wave will be influenced by obstacles.

While the team certainly enjoy the excitement of creating explosions for their experiments (“Of course it’s fun to blow stuff up!” says Andy, a technician in the lab), the work conducted in the Blast and Impact Diagnostics Lab has a much greater purpose and will ultimately help save lives and protect infrastructure from the devastating effects of explosions.

BLAST AND IMPACT DIAGNOSTICS LAB

BLAST AND IMPACT DIAGNOSTICS LAB

Department of Civil and Structural Engineering, University of Sheffield, UK

FIELD OF RESEARCH: Engineering

RESEARCH PROJECT: Investigating explosions and their effects on structures

FUNDER: Engineering and Physical Sciences Research Council

BLAST AND IMPACT DIAGNOSTICS LAB

BLAST AND IMPACT DIAGNOSTICS LAB Department of Civil and Structural Engineering, University of Sheffield, UK

FIELD OF RESEARCH: Engineering

RESEARCH PROJECT: Investigating explosions and their effects on structures

FUNDER: Engineering and Physical Sciences Research Council

EXPLORE A CAREER IN ENGINEERING

• A-levels in physics and maths are necessary for most engineering courses, but Gen and Sam R. both suggest considering creative subjects too, to ensure diverse ways of thinking and connection with real-world issues.

• Sam C. and Sam R. are civil engineers. The Institute of Civil Engineers (www.ice.org.uk/what-is-civil-engineering) provides a wealth of resources about careers in civil engineering, including advice about what subjects to study and interviews with civil engineers at all stages of their careers.

• Gen is a chartered mechanical engineer. If you want to achieve chartered engineer status, check that your university courses are accredited by a national engineering body such as the Institution of Mechanical Engineers (www.imeche.org) or the Royal Academy of Engineers (www.raeng.org.uk)

• Gen recommends finding work experience to learn more about what engineering actually is. “Engineers work everywhere – factories, laboratories, design offices, consultancy firms…” she says. “Go and see the variety of engineering roles for yourself.”

• Not all engineering roles require a university education. Andy is a technician at the Blast and Impact Diagnostics Lab. He advises students to be hands on and open to learning new skills if they are interested in working in an engineering lab. “Offer to help wherever you can,” he says. “You never know where it might lead!”

MEET DR SAM CLARKE

I’m the Principal Investigator of the Blast and Impact Diagnostics Lab. This means I’m in charge of ensuring we deliver what we promised – which recently involved spending £1 million on new equipment! It’s great to finally have the resources to investigate ways to reduce the impact of explosions on the world around us.

I enjoy the varied nature of my job, and the fact that no two days are the same. One day I’ll be in the classroom teaching students, and the next I’ll be out on-site blowing things up!

When British troops were deployed to Iraq and Afghanistan, we realised we had an opportunity to help protect them through understanding the engineering properties of soil. The characteristics of the soil in which an explosive is buried will determine how dangerous the explosion will be. I’ve been involved with the engineering aspect of explosions ever since.

I’ve always been interested in construction. I loved LEGO sets as a kid, and still do! I couldn’t decide between architecture and engineering, so I completed the University of Sheffield’s unique Structural Engineering and Architecture degree, which let me delay my professional career choice. I soon realised that I loved engineering, especially soils, which always provide a challenge.

I always have a project on the go outside of work, mainly home improvement projects or furniture design. I’m also a very keen cyclist and having the Peak District on my doorstep is great.

MEET DR SAM RIGBY

My research focuses on understanding the loading that acts on structures following an explosion. The forces produced by explosions far exceed those normally considered in civil engineering, and they are applied and removed so suddenly that they introduce all sorts of interesting behaviour into structures.

My role in the lab focuses on numerical modelling and developing quick methods for predicting blast loading parameters. These methods will be based on our explosion experiment results and could provide a ‘shortcut’ to the more computationally demanding solutions currently in use. We aim to provide simple techniques for practicing engineers to predict the effects of explosions.

I’ve seen close to 100 explosions in my lifetime, and it never gets boring! I like the fact that we get an insight into this hidden world where events happen so quickly, through our ultra-high-speed cameras, so we can see what is really going on. Plus, I love when I receive the results of a particular test – looking at the screen and thinking, “I’m the only person in the world who knows this.” It’s quite a feeling!

Civil engineering, by definition, is about people. My research ultimately aims to protect people from explosions and knowing that my work could save lives really spurs me on. I also love the variety of civil engineering, the mix of practical work with number crunching. This is very apparent in my job, where my time is split between blowing things up in a muddy field and computer programming at my desk.

I was always designing things when I was younger. I remember sketching out a toy giraffe, including a cross-section, and giving the blueprint to my mum to pass on to Santa ready for Christmas! I carried this inquisitive nature into school and became interested in maths and physics. I initially thought I wanted to be an architect, but as soon as I realised engineering involved creative design as well as mathematics, I was sold.

Outside of work, I play for my local rugby team and enjoy playing guitar. I am also a huge craft beer nerd – we’re blessed to have several great breweries in Sheffield. And I love walking in the Peak District with my wife and young son.

MEET PROFESSOR GENEVIEVE LANGDON

I am a mechanical engineer by training. This field is very broad and covers anything connected to how things move or respond to loads. This feeds into industries such as manufacturing, structures, energy production and fluid motion. My specific interest is much more niche, namely how materials and structures respond to explosions. Explosions and their effects are both devastating and fascinating to me.

I would be lying if I said I don’t enjoy blowing things up! I enjoy the challenge of unpicking what happens during an explosive event, and how to use this information to prevent damage and injury in the real world. The physics and engineering challenges involved require a clever team, and I love being able to work with excellent people.

I enjoy the mix of different things I get to work on. Engineering is at the interface of science and the real world – taking theory and putting it into practice. I like the hands-on nature of experiments, and the chance to use my brain to interpret their results.

When I was a child, I wanted to be the first woman in space, but was beaten to it! When I was about 12, I learnt about the field of engineering (and that being an engineer didn’t mean being a car mechanic) and set my eyes on that for the rest of my time in school. I was one of only two girls in my school to take Design & Technology at GCSE. My one regret is being too narrowly focused on science-leaning subjects – I wish I had taken GCSE drama! I thought arts and engineering are incompatible, but they certainly are not.

Outside of work, I spend a lot of time with my family, and I like to sing, write poetry and read. I also preach at my local church and am doing an online theology degree in my spare time. Though all these interests are very different to engineering, I find the range of perspectives they give me very stimulating and life-giving.

MEET ANDY HIBBERT

I’m a technician in the Blast and Impact Diagnostics Lab. I run a selection of high-speed video cameras, as well as doing on-site photography. I also help with the general day-to-day running of the laboratory.

The sense of achievement I get when our hard work produces great results is the best part of this project – as well as the chance to blow stuff up! I also enjoy getting to watch videos back in super slow motion, seeing exactly what happens during an explosion.

As a technician, a typical day starts off with a team meeting and discussing the plans for the day. Then we will prepare the test area and I will set up the cameras. Finally, it’s time to make a bang and retrieve the data we have just captured.

It was through photographing BMX riding that I became interested in slow-motion filming. I understood the fundamentals of photography and became involved with filming explosions, ultimately working with lots of different types of cameras and equipment as a career.

THE TEAM’S TOP TIPS

01 The better you do at school, the more choices you have in life. Try and give your best to whatever you do, without burning yourself out.

02 Find something that you enjoy, sparks your imagination and gets you excited to learn more. Don’t be afraid to follow what you love.

03 Don’t be put off if you don’t achieve what you want straight away. Things can take time.

04 Show interest and talk to people! Enjoy yourself and try to make a positive difference to the people around you.

Do you have a question for Sam, Sam, Gen or Andy?

Write it in the comments box below and Sam, Sam, Gen or Andy will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)

Hi

Question. There was an explosion near Moscow March 2. I believe drone hit compressor station. I’m trying to find , and can’t, seismic activity for that area. Kolomna, Russia..Site of gazprom natural gas facility. I want to “ see” how much damage was done, before TASS makes a statement. Is there a site that I can monitor seismic activity, real time?

Thanks

Carol Dailey

Pennsylvania, USA

Dear Carol,

Thanks for getting in touch with me via the futurum comments.

How close you need the monitoring to be done depend on how large the blast was. For volcanic eruptions, and large explosions like Beirut worldwide data can be used.

I’ve attached an open-access paper on the topic and have reached out to some of my colleagues about where the best seismic data can be found. Please see below.

https://ngawest2.berkeley.edu/

https://link.springer.com/content/pdf/10.1038/s41598-021-93690-y.pdf

Hope this helps.

Sam

To start with I am not an engineer, but rather a stationary battery technician/analyst. Though they are rare, there are explosions that occur within some vented lead acid cells, that initially appear to have an unknown cause. But I think that we may have discovered part of the cause of the explosions.

During normal float charging these generate hydrogen and oxygen gasses, which are combustible, and if I understand correctly the volume of gas expands to a greater volume than when it is just the hydrogen and oxygen gasses.

Is there a formula that can be used to calculate the volume of the exploded gas. For example, if I have a one cubic centimeter of hydrogen oxygen gas, and it explodes, how large a volume of space will it displace? I am not even sure if I am asking this correctly but would appreciate any help possible.

Thank you in advance.

Peter DeMar

We have contacted Dr’s Rigby and Clarke but unfortunately your question lies beyond their field of expertise. Apologies they could not be of assistance and thank you for your very interesting question.

Why is it that companies blasting in Residential areas cause damage to drywall seams and yet continually deny any culpability claiming these homes are outside the safe perimeter where blasts occur. They also claim to measure every blast near residential areas when in fact that is not true.