The engineering behind Evolutor

Professor Tuck Seng Wong, based at The University of Sheffield in the UK, leads a team focused on applying the concept of Darwinian evolution to engineer biological systems for industrial applications

TALK LIKE A BIOMANUFACTURER

BIOECONOMY — the economic potential of harnessing the power of bioscience

ENZYMES — the proteins responsible for catalysing all chemical reactions in cells

EVOLUTION — the change in the characteristics of a species over several generations, which relies on the process of natural selection

EXPERIENTIAL LEARNING — the process of learning through experience, more narrowly defined as ‘learning through reflection on doing’

GENOME SEQUENCING — the process of determining the entirety, or nearly the entirety, of the DNA sequence of an organism’s genome

NATURAL SELECTION — the process through which populations of living organisms change and adapt

SURVIVAL OF THE FITTEST — a phrase that originated from Darwinian evolutionary theory as a way of describing the mechanism of natural selection

Charles Darwin revolutionised our understanding of life on Earth when he presented his concept of natural selection in his ground-breaking book On the Origin of Species in 1859. Natural selection is the process by which living organisms change and adapt and is a key mechanism of evolution. Organisms that are better adapted to their environment are more likely to survive, which means the genes that enabled their survival are more likely to be passed on.

We have come a long way since Darwin published his concepts, and engineers and scientists have borrowed the concept of ‘survival of the fittest’ and applied it to engineering biological systems for industrial applications. Professor Tuck Seng Wong, a chemical engineer based at the University of Sheffield, explains this process of mutation and selection with this very useful analogy: “Mercedes has dominated the Formula 1 race by winning the constructors’ titles (that celebrates the car designers rather than the drivers) consecutively since 2014. Among the F1 constructors (e.g., Ferrari, Williams, McLaren, Red Bull, etc., which are examples of variation), Mercedes has proven to be the best chassis and engine manufacturer in the F1 race, and so is the ‘chosen’ winner.” So, how does this relate to Tuck’s work?

In our evolving world, where climate change is forcing us to look at manufacturing and technology from a new perspective, Tuck and his team believe that applying this Darwinian concept to biomanufacturing will help provide the solutions we need for a sustainable future. Tuck explains, “We deliberately introduce mutations into a biological system (e.g., a gene encoding an enzyme) and apply artificial selection to perpetuate a desirable trait (e.g., an enzyme with higher activity) in order to expedite the process of evolution.”

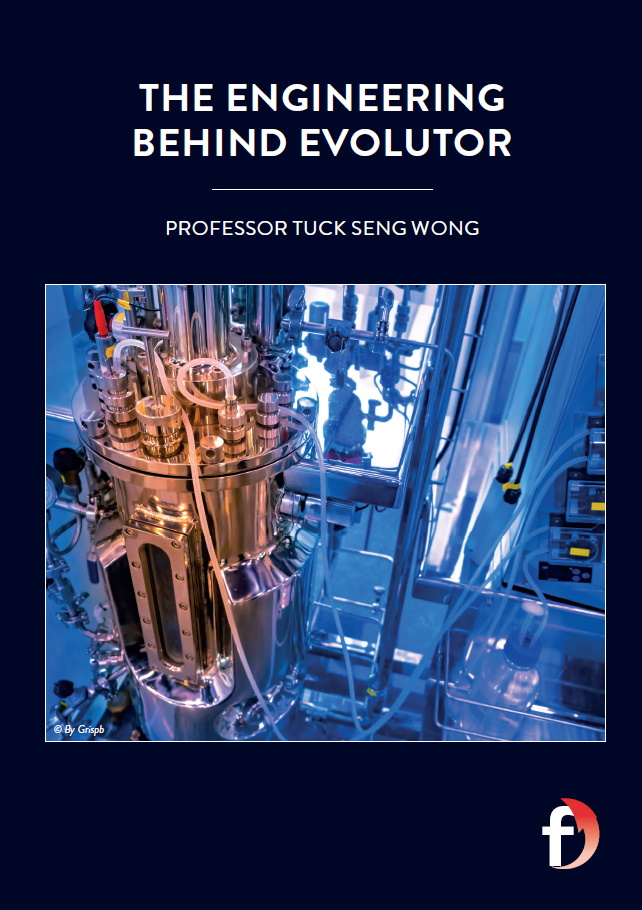

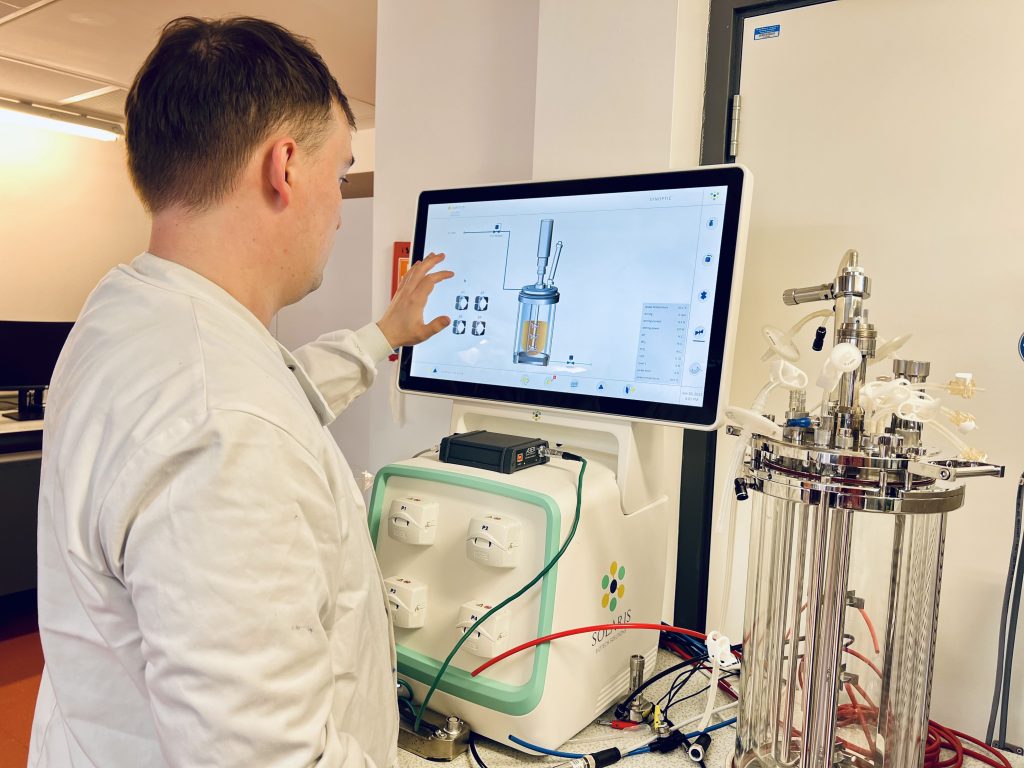

EVOLUTOR

By evolving microbes, the team can optimise natural resources. Tuck explains, “Bacteria and yeast can be adapted to turn waste products into food ingredients, biodegradable plastics, biofuels and other valuable resources.” Microbes need to be evolved and adapted to do these specific jobs, and Tuck and his team have developed Evolutor to do just that. The Evolutor technology enables them to evolve microbes with specific properties and, importantly, with accuracy and predictability.

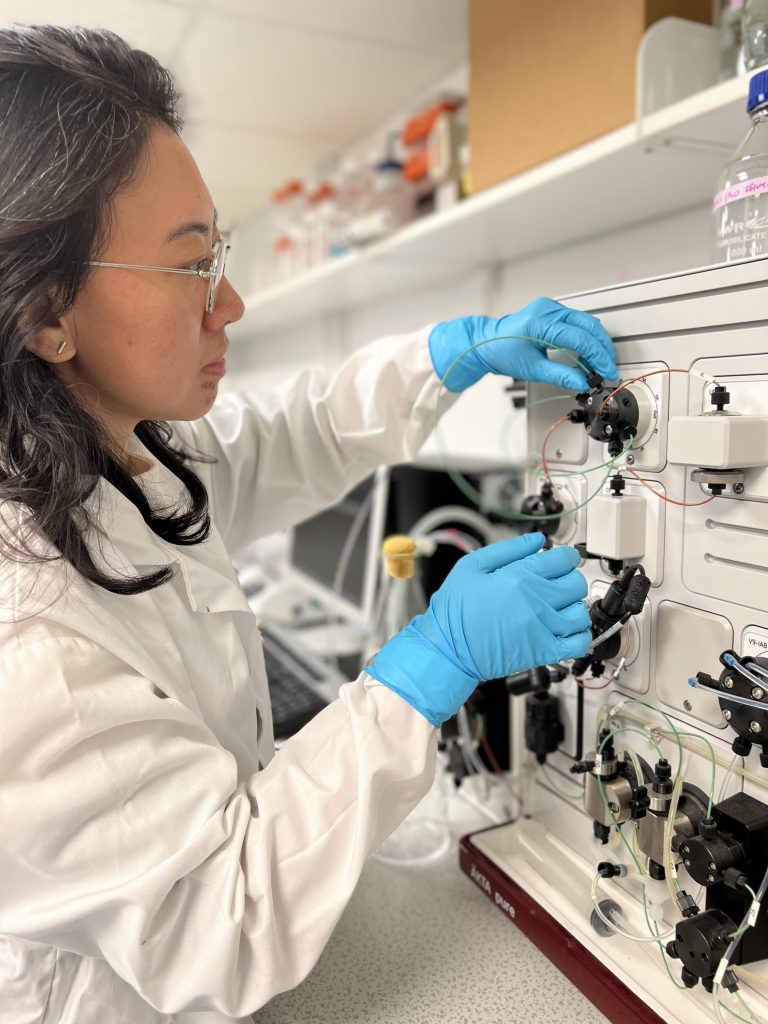

The elements of Evolutor which make such precision possible have been developed through experiential learning – learning by doing. The team in Sheffield has over 40 years of accumulated research experience in applying an evolutionary approach to engineering biology. “Our advances are the manifestation of our experience (both good and bad) in laboratory evolution,” says Tuck. “The intelligent control of Evolutor allows us to automate the laborious workflow of evolution, bypass human intervention, reduce human error, lower the risk of contamination and achieve a predictable and positive outcome of laboratory evolution.”

GENOME SEQUENCING

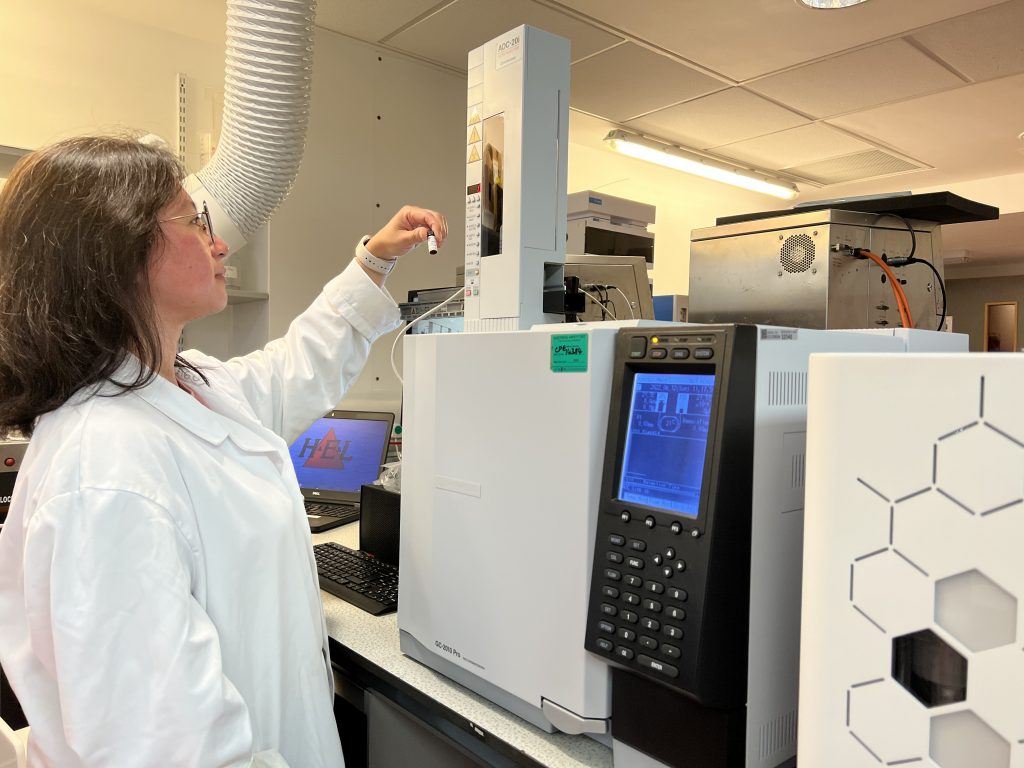

Genome sequencing allows the team to ‘read’ the genetic alphabets in a genome. “By comparing a DNA sequence against a reference, engineers or scientists can quickly identify the genetic variations that are responsible for a trait,” explains Tuck. “For example, if we isolate a baker yeast variant that produces more biofuel, such as isobutanol, we will be able to understand the genetic basis of this improvement in productivity through sequencing the genome of this yeast variant. Mutations responsible for trait improvement are commonly referred to as beneficial mutations.”

HARDWARE DESIGN

The team believes that, in engineering, simplicity is often the best solution, so it has ensured its hardware and software are not complicated. They are designed to be goal-oriented, in that they do what they are supposed to do, and user-focused, so they can be used by target users. These product design principles have enabled the team to build a ‘fit-for-purpose’ device that enables its users to automate laboratory evolution to save time and resources. The data collected by the Evolutor provide a more predictable evolution outcome – microbes can be optimised as intended and without any lengthy processes or unexpected errors.

EVOLVING PROPERTIES

Evolutor has been built in response to the ‘Bio Revolution’, the biological science innovations that are able to transform economies, societies and our lives. These innovations are designed to help us tackle the global challenges we face, from climate change to pandemics. “Evolutor is a clever device, which allows us to manipulate and control the conditions of microbial growth. Through increasing or reducing the temperature of the microbial cultivation chamber, we can select microbial sub-population that tolerates high temperature (evolving for thermotolerance) or low temperature (evolving for cold adaptation),” explains Tuck. “Depending on how we design the experiment or operate the Evolutor, we can evolve a wide range of microbial properties such as carbon utilisation (microbes need food to grow and to manufacture a product), pH tolerance, inhibitor tolerance, product tolerance and productivity.”

APPLICATIONS IN MANUFACTURING

Evolutor’s microbe optimisation capabilities can be widely applied across many biotech industries. Due to the team’s evolution-based approach, it is able to optimise any microbe, regardless of the availability or confidentiality of genetic information. “The next-level microbe development capabilities of the Evolutor technology are especially relevant for bio-manufacturers in food and drink, pharmaceuticals and biologics, chemicals, agri-tech, biofuels, nutritional ingredients and microbiome health, materials, and flavours and fragrances,” says Tuck. The breadth of application is huge; the potential impacts bigger still.

TEAM SUCCESS

Tuck is keen to emphasise the importance that teamwork has played in the development of Evolutor. For him, it would not have been possible to develop Evolutor without the input of every team member who brings their own experience, skill, enthusiasm, commitment, persistence and hard work to the project.

THE NEXT STEPS

Tuck and his team now want to understand biological blueprints through the lens of evolution. “Biology is complex. Microbial cell factories can manufacture fascinating molecules (e.g., bioplastic and antibiotics). How these factories are designed and constructed is still a puzzle to engineers and scientists,” explains Tuck. “Through laboratory evolution, we hope to develop a better understanding of the genetic makeup of a microbe, the gene function and how the genes are regulated.”

PROFESSOR TUCK SENG WONG

PROFESSOR TUCK SENG WONG

Department of Chemical and Biological Engineering, University of Sheffield, UK

FIELD OF RESEARCH: Biomanufacturing

RESEARCH PROJECT: Applying the concept of Darwinian evolution to engineer biological systems for industrial applications

FUNDERS: Royal Academy of Engineering, Research England, Innovate UK, Biotechnology and Biological Sciences Research Council’s (BBSRC), The University of Sheffield

ABOUT BIOMANUFACTURING

Biomanufacturing is a type of manufacturing or biotechnology that makes use of biological systems to produce a range of applications for use across various industries. Scientists within the field can come from several different arenas, including chemical engineering, biochemical engineering, protein engineering, engineering biology, microbiology, molecular biology and genetics.

OPPORTUNITIES

Tuck and his team’s research helps the UK make the transition into a circular bioeconomy and build a sustainable future. “We turn sustainable and economical carbon feedstock into bio-products,” says Tuck. “Ultimately, this brings direct benefits to society.”

“Mother Nature is the best engineer!” explains Tuck. “She has evolved some of the most interesting solutions for us to exploit (e.g., microbes that can capture and utilise CO2, microbes that produce bioplastics, microbes that make hydrogen, etc.). These are the opportunities for our next generation of biomanufacturers!”

PATHWAY FROM SCHOOL TO BIOMANUFACTURING

Tuck recommends students study mathematics, physics, chemistry and biology to enter the field of biotechnology and biomanufacturing.

You will usually need a degree in a relevant scientific subject such as biotechnology, bioscience, microbiology, biochemistry or chemical engineering.

https://nationalcareers.service.gov.uk/job-profiles/biotechnologist

EXPLORE CAREERS IN BIOMANUFACTURING

• The Department of Chemical and Biological Engineering, where Tuck and his team are based, offers public outreach to teach people about this field, and Tuck often delivers talks to sixth form colleges and international schools.

• Built with Biology has some great information about the mind-blowing innovations that are happening across the bio-industry.

• There are a range of science magazines and professional engineering institution webpages that could prove useful to those interested in pursuing a career in biomanufacturing. The Chemical Engineer, IChemE, Royal Academy of Engineering and The Scientist are notable examples.

• According to Prospects, the starting salary for graduates generally is between £19,000 and £24,000, although more experienced biotechnologists can earn between £25,000 and £50,000.

MEET PROFESSOR TUCK SENG WONG

I wanted to be a medical doctor when I was young. Unfortunately, my parents couldn’t afford my tuition fee in a medical school. I started my engineering education after winning a full scholarship, offered by the Department of Chemical Engineering at the National University of Singapore. It turned out that engineering suits me!

Reference

https://doi.org/10.33424/FUTURUM292

I have been greatly inspired by Nobel Laureate Professor Frances H. Arnold (Nobel Prize in Chemistry 2018). I was awarded a Summer Undergraduate Research Fellowship by the California Institute of Technology when I was still an undergraduate student studying chemical engineering. The fellowship allowed me to spend time in Arnold’s lab, and my passion in laboratory evolution was kindled by this experience.

I owe my success to not giving up! I am always curious and want to do more and better.

A eureka moment in my career was when I received a Proof of Concept fund from the Royal Academy of Engineering for my Evolutor idea on my second attempt (I failed in my first attempt). Without this fund, it would not have been possible for us to establish Evolutor Ltd. A Proof of Concept fund is by invitation only. The scheme is only open to academics holding fellowships awarded by the Royal Academy of Engineering. I held two fellowships from the Royal Academy of Engineering – an Industrial Fellowship in 2016 and The Leverhulme Trust Senior Research Fellowship in 2019.

My top three proudest achievements are: establishing Evolutor Ltd, publishing my protein engineering textbook and winning six awards for Excellence in Learning & Teaching.

My ambitions for the future: (1) continue to create impact through the science we do in Sheffield, (2) help South-East Asian countries (where I come from) to develop their Research and Development (R&D). I am currently a Visiting Professor at BIOTEC in Thailand and an Adjunct Professor at the Bandung Institute of Technology in Indonesia, (3) coach young researchers from Black, Asian and minority ethnic (BAME) backgrounds.

JOE PRICE

Joe describes himself as “the interface between the team’s research and the commercial world”.

“I’ve always loved biology and nature. This passion inspired me to study zoology and introduced me to the exciting world of bio-industry.

My career, so far, has been driven by wanting to disrupt old-fashioned systems and industries. My biggest eureka moment was when I first discovered how our bio-factories can change the world.

Speaking to businesses across the globe and learning about everything they are doing to solve some of our world’s biggest problems have been highlights for me.

My ambition is to lead Evolutor Ltd. to be the leading developer of biological factories in the UK and, one day, beyond!”

A DAY IN THE LAB IN THREE WORDS:

exciting, thought-provoking, busy!

JOE’S TOP TIP: Start to think now about what your interests are, how you can pursue them and how you can make a positive impact in the world.

DR IWONA SMACZYNSKA-DE ROOIJ

Iwona uses almost thirty years of expertise in physiology, molecular biology, and genetics of common and pathogenic yeasts to construct new strains that can withstand a variety of growing conditions and produce substances useful in medicine, food and chemical industries.

“The person who inspired me to become a scientist was Professor Tomasz Umiński, who later became my zoology lecturer. I first met him when I was eleven years old. He told me then that there is nothing more beautiful than the variety and complexity of life, and that if I decided to study its secrets in the future, it might not be an easy road, but it would certainly be a rewarding one. Throughout my scientific career, I have always worked with yeasts, trying to unlock the secrets of their life and function. Now, it is time for me to make changes in them and alter their functioning myself.”

A DAY IN THE LAB IN THREE WORDS:

genetic-manipulation, cultivation, research

IWONA’S TOP TIPS: Do not to be afraid to challenge yourself. Do not give up your dreams.

ASSISTANT PROFESSOR KANG LAN TEE

Kang Lan co-creates ideas with Tuck and applies over twenty-years’ engineering biology experience to the research.

“I find the idea of applying scientific knowledge to solve real life challenges very exciting and the outcome very rewarding.

I always enjoyed STEM subjects in school. I liked their logic and how they help us understand the things around us. From everyday events like how the colours in rainbow are created and why fish do not freeze in winter, to more complex systems like how the age-old concept of evolution can improve industrial biomanufacturing.

Developing Evolutor, I enjoyed working with this great team. The incorporation of Evolutor Ltd. To enable more people to benefit from our technology is also a highlight.”

A DAY IN THE LAB IN THREE WORDS:

design, analyse, solve

KANG LAN’S TOP TIP:

A good plan is half the battle won, but the unknown is worth exploring.

MATTHEW HUTCHINSON

Matthew is a research scientist and manager providing laboratory support to the group.

“Growing up, I always had an interest in science, and I’ve been lucky enough to follow my interest into my career.

I’ve worked in multiple labs in different research areas, but all of them have helped me grow as a scientist and develop various skills I use in my research today. My eureka moment was when I learned it’s okay to ask questions!

It’s always interesting working on the translation of scientific principle into something practical – with Evolutor, it’s exciting because it’s so novel and so close to commercial use. I want to be able to see something in the real world and be able to say, I helped make it happen.”

A DAY IN THE LAB IN THREE WORDS:

plan, experiment, analyse

MATTHEW’S TOP TIP:

Be adaptable and willing to learn new things. You never know how exactly your career will develop and what opportunities may become available.

Do you have a question for Tuck and the Evolutor team?

Write it in the comments box below and Tuck and the Evolutor team will get back to you. (Remember, researchers are very busy people, so you may have to wait a few days.)

I would like to congratulate the whole evolutor team for a wonderful concept which hopefully will help all of us. I wanted to say that I found out about your project thanks to involvement of Iwona Smaczynska de Rooij which I met 20 years ago in Veenendaal. I’m really emotional to see such a revolutionary and courages ideas put in life. I hope to see use of this technology in managing plastic waste. Thank you for your dedication and hard work. Kind regards Wiga